In the fast-paced realm of port logistics and freight transport, the safe and efficient operation of container handling equipment remains paramount. With global container throughput exceeding 800 million TEUs annually, mishandling or operational errors risk costly delays and severe accidents. This technical guide unpacks critical safety protocols, operator training essentials, and emergency response strategies to empower B2B export enterprises, shipping companies, and terminal operators to optimize their container handling workflows.

Scientific management begins with rigorous adherence to equipment stability and environmental adaptability. Container cranes, reach stackers, and straddle carriers must operate within manufacturer-specified limits, considering load ratings, wind speed thresholds (typically below 20 m/s), and ground conditions. According to the International Maritime Organization (IMO), approximately 60% of container-related accidents involve equipment instability or overloading, underscoring the need for real-time monitoring and periodic equipment diagnostics.

Environmental factors such as uneven terrain, temperature extremes, or heavy rainfall affect equipment performance. Implementing automated sensors and IoT-enabled status alerts can proactively mitigate risks before crises arise.

Skilled operators are the first line of defense against accidents. A structured training regimen covering mechanical operation, safety regulations, and hazard recognition must culminate in recognized certifications. Industry best practices recommend a minimum of 40 hours of theoretical and practical training, supported by periodic refresher courses every 12 months.

Psychological preparedness also plays a crucial role. Operators need a strong safety mindset, cultivated via simulations demonstrating emergency scenarios such as load swinging, power failures, or entrapment. Some advanced programs incorporate VR-based modules for immersive experience.

Despite preventive efforts, incidents may occur. Establishing a clear, hierarchical emergency plan enables swift containment and recovery. Standard procedures include immediate equipment shutdown, site evacuation, and coordinated communication with safety officers.

Risk control strategies entail regular drills, installation of fail-safes such as anti-collision systems, and maintaining a comprehensive incident log for root cause analysis. Data from the U.S. Occupational Safety and Health Administration (OSHA) indicates that workplaces with documented emergency protocols reduce accident severity by up to 45%.

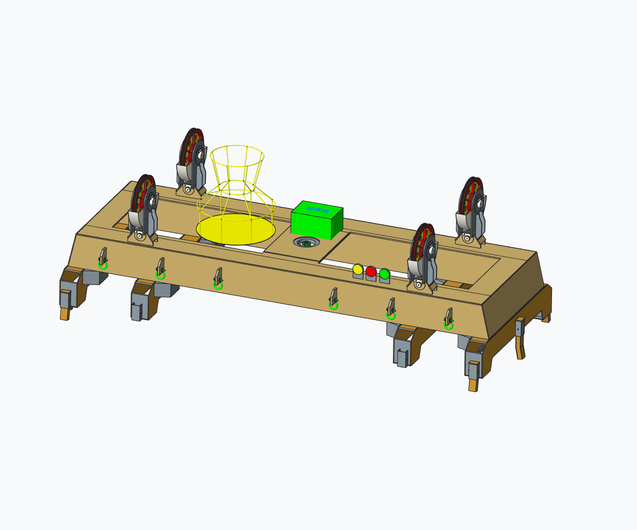

Titanium Heavy Industries (钛鼎重工), a global leader in container handling equipment manufacturing, exemplifies innovation through its integrated risk management systems. By deploying adaptive load sensors and AI-powered operational analytics, their equipment maintains peak stability even under challenging conditions such as crosswinds and high-frequency loading cycles.

In a recent project at a Mediterranean terminal, Titanium’s machinery improved turnaround times by 18% while reducing minor incidents by 33%, resulting in enhanced operational throughput and workforce safety.

| Common Accident | Primary Cause | Recommended Prevention |

|---|---|---|

| Load Drop | Improper rigging or exceeding load limit | Routine equipment inspection, load verification, operator training |

| Crane Tip-over | Unstable ground or high wind conditions | Site condition assessment, wind monitoring systems, operational limits enforcement |

| Operator Error | Inadequate training or fatigue | Comprehensive training, shift rotation, and on-site supervision |

Elevating operational safety is reinforced by diverse educational resources. Industry whitepapers, step-by-step operation manuals, and concise video tutorials enhance comprehension and adherence to best practices. Titanium’s proprietary online platform offers certified courses with interactive Q&A sessions, nurturing a community focused on safety innovation.

Content optimized for search engines significantly expands reach among key stakeholders. Targeting keywords such as "container handling safety standards," "lifting equipment risk mitigation," "crane operator certification," and "logistics equipment management" can increase organic traffic by over 40%. Titanium’s content strategy ensures these industry-specific phrases are naturally embedded, providing both visibility and authority.

Collaborative promotion with industry associations and equipment users further amplifies trust and content dissemination, fostering an ecosystem of shared safety responsibility.

Unlock the full potential of your container handling operations with Titanium Heavy Industries’ cutting-edge solutions. Experience firsthand how scientific management coupled with advanced equipment elevates safety and boosts your logistics productivity.

Discover Titanium Heavy Industries’ Innovative Container Handling Solutions