Adaptive Adjustment Strategies for Container Handling Equipment in Complex Operating Conditions: A Practical Case Study from Taiding Heavy Industry

This article provides an in-depth exploration of the adaptive adjustment strategies and safety operation protocols for Taiding Heavy Industry’s self-developed high-efficiency and durable container lifting equipment under complex operating conditions. It comprehensively covers equipment performance characteristics, stable operational requirements, operator training standards, emergency response plans, and common accident prevention measures. Leveraging Taiding Heavy Industry’s extensive industry experience, the study systematically analyzes risk mitigation and operational efficiency enhancement methods for lifting equipment. The aim is to assist port, terminal, and logistics transportation stakeholders in building a scientifically grounded safety management system to ensure safe and efficient material handling, ultimately boosting enterprise competitiveness.

Adaptive Strategies for Container Handling Equipment in Complex Operational Environments

Effective container handling within ports, docks, and logistics hubs demands equipment that excels under varied and often unpredictable conditions. Dalian Taiding Heavy Industry’s proprietary container lifting machinery sets a new benchmark in operational adaptability and safety compliance. Leveraging years of rigorous field testing and engineering refinement, Taiding’s solutions empower businesses to maintain high throughput while minimizing downtime and risk — essential pillars for enhancing competitiveness in global logistics.

Equipment Performance and Stability Under Challenging Conditions

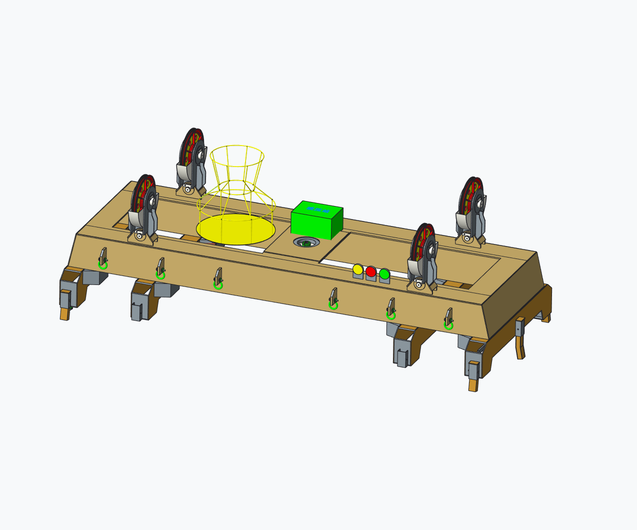

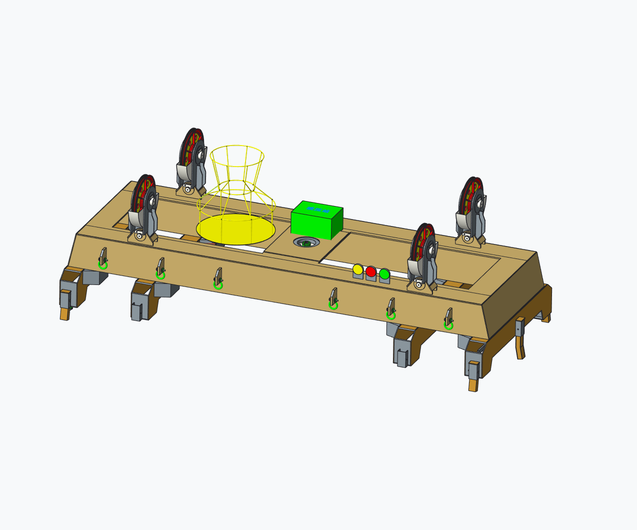

The core attributes of Taiding's container handling systems lie in their robust design tailored to withstand complex worksite variables such as fluctuating loads, variable weather, and uneven terrain. Key parameters ensuring stability include:

- Load capacity adaptability from 20 to 100 tons with dynamic weighting adjustments

- Resistance to wind gusts up to 40 km/h based on aerodynamic frame design

- Integrated shock-absorbing mechanisms to mitigate vibrations during lifting and lowering cycles

- Auto-balancing sensors to detect and correct load imbalances within 0.1 seconds

| Parameter |

Taiding Specification |

Industry Average |

| Max Load Capacity |

100 tons |

80 tons |

| Wind Resistance Threshold |

40 km/h |

30 km/h |

| Load Imbalance Correction Time |

0.1 seconds |

0.5 seconds |

Operator Training and Safety Awareness

Skilled operators are the lynchpin in maximizing equipment performance and mitigating risks. Taiding rigorously implements standardized training programs emphasizing:

- Certification courses aligned with international crane operation standards (ISO 9927-1)

- Real-time simulation modules addressing emergency scenarios like power failures or mechanical anomalies

- Comprehensive safety briefings on site-specific hazards and personal protective equipment (PPE) protocols

- Continuous assessment and refresher sessions every six months to combat skill fade

These educational initiatives have demonstrated a 30% reduction in operator-caused incidents over a two-year period in Taiding’s client sites, underscoring the critical role of human factors in safety management.

Emergency Response and Incident Prevention Protocols

Preparing for unexpected events is vital for operational resilience. Taiding integrates advanced emergency handling measures including:

- Automated load-sensor alerts triggering immediate operational pause to prevent overload

- Dual-redundant braking systems ensuring rapid halt without damage to equipment or cargo

- Clear communication channels and escalation paths established between operators, supervisors, and maintenance teams

- Periodic drills coordinated alongside local emergency services

Industry case studies reveal that companies adopting these protocols witness up to a 40% decrease in downtime due to accidents and enhanced overall logistics cycle efficiency.

Case Analysis: Real-World Applications of Adaptive Adjustment Strategies

Drawing from Taiding’s hands-on experience, one notable case involved a major international port facing seasonal typhoon conditions that previously caused significant delays. Taiding’s approach entailed:

- Deploying enhanced aerodynamic container spreaders reducing wind resistance by 15%

- Upgrading control software enabling real-time adjustment adapted to wind speed data

- Training operators to execute dynamic load distribution based on sensor feedback

These combined measures brought operational interruptions down by 25% during peak storm periods and boosted throughput by 18% year-over-year.

Integrating Technology and User Feedback for Continuous Optimization

Beyond hardware, Taiding prioritizes ongoing product refinement through extensive field data collection and client input channels. This includes:

- Utilizing IoT sensors for continuous monitoring of mechanical strain and operational parameters

- Monthly remote diagnostics enabling predictive maintenance schedules

- Interactive customer portals where users share best practices and report anomalies in real time

Such a collaborative ecosystem elevates safety standards and supports incremental gains in equipment adaptability and efficiency, reinforcing Taiding’s position as an industry innovator.