In the heavy industries of metal smelting, port logistics, warehousing, and construction, one challenge consistently stands out: how to handle heavy plate materials efficiently while ensuring worker safety. High-strength plate clamps powered by multi-drive systems have emerged as a game-changer. From mechanical to hydraulic, electric, and pneumatic operations, coupled with intelligent safety devices, these industrial clamps address the persistent bottlenecks of productivity and risk in material handling.

These clamps come with lifting capacities ranging from a modest 8 tons up to a robust 550 tons. Their compact yet powerful designs deliver unmatched flexibility in maneuvering bulky plates, redefining what heavy material handling equipment can achieve across various sectors.

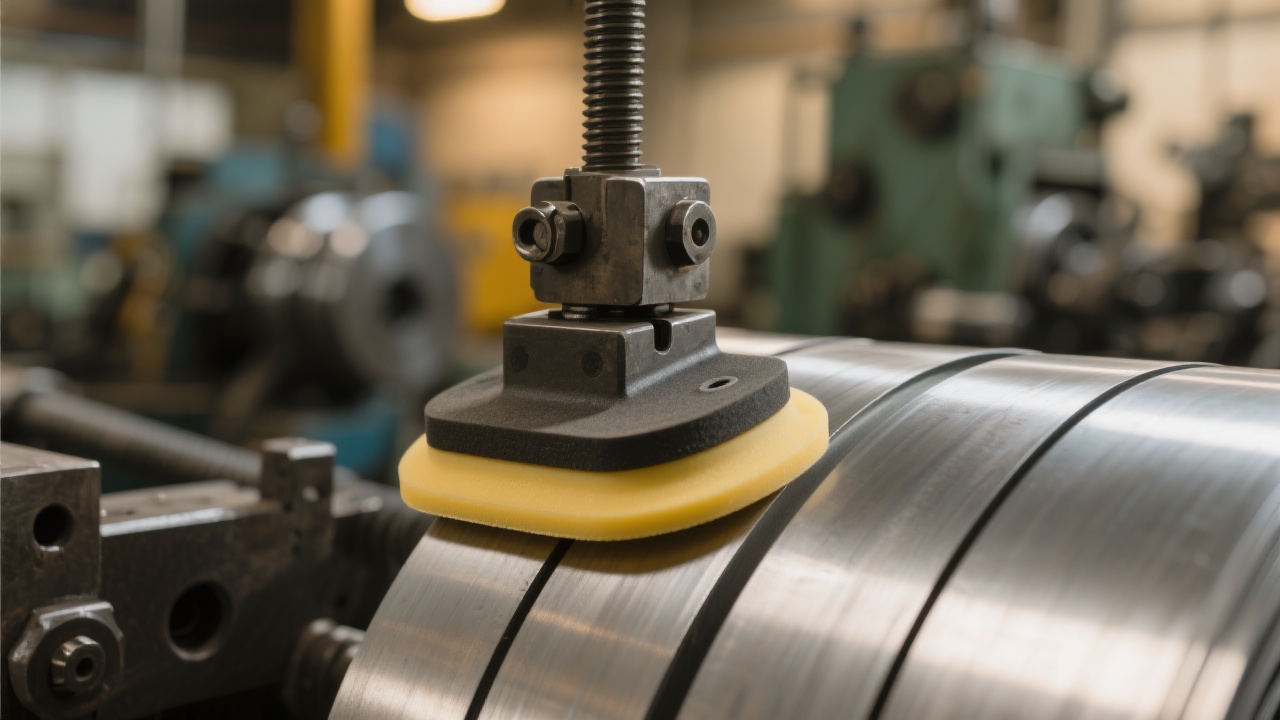

At the heart of these clamps is a high-strength alloy steel body engineered to withstand extreme stress while maintaining durability. The lever principle design optimizes force transmission, making load securing highly effective without excessive operator effort. Multiple driving modes—mechanical, electric, pneumatic, and hydraulic—offer adaptable performance tailored to specific site demands and energy availability.

Safety isn’t an afterthought but a primary focus. Integrated limit switches and smart locking feedback mechanisms guarantee secure grip confirmation, thereby minimizing accidents caused by clamp slippage or operator error. Such built-in devices also allow real-time operational monitoring, facilitating preventive maintenance and reducing unexpected downtime.

The metal smelting sector demands clamps that can cope not only with heavy weights but also with high ambient temperatures and corrosive environments. Our featured clamps utilize corrosion-resistant coatings and heat-tolerant designs. These features ensure operational stability even during continuous hot-metal handling.

In the bustling port terminals, space constraints and rapid loading cycles require compact clamp designs with pneumatic drives for fast, repeatable operations. Here, these clamps' modular systems allow seamless integration with existing gantry cranes and forklifts.

Warehouses benefit enormously from electric and mechanical modes which offer quiet and clean operation, ideal for indoor environments. The precise gripping force controls reduce the risk of material damage during stacking and unstacking tasks.

Meanwhile, construction and heavy equipment sectors appreciate the robust hydraulic models for their superior grip force and adaptability to rugged terrain, ensuring plates remain secure even amid vibrations and shocks.

Operators report notable ease of use thanks to intuitive controls and ergonomic designs that reduce fatigue. Feedback systems visually and audibly confirm clamp engagement and release, significantly mitigating risks stemming from human error during high-stress operations.

Moreover, the clamps’ compact form factors facilitate maneuvering in tight spaces, expediting workflows without compromising load security. Such improvements have led to measurable productivity gains, lowering labor costs and enhancing jobsite safety records.

| Parameter | Mechanical Drive | Electric Drive | Pneumatic Drive | Hydraulic Drive |

|---|---|---|---|---|

| Load Capacity (tons) | 8 - 150 | 10 - 200 | 8 - 100 | 50 - 550 |

| Precision Control | Moderate | High | Moderate | Very High |

| Operational Noise | Low | Very Low | Medium | Medium |

| Maintenance Complexity | Low | Moderate | Moderate | High |

Choosing the proper drive system depends on your specific operational environment and priorities. For example, hydraulic drives shine in ultra-heavy lifting with the highest precision and grip strength but come with increased maintenance demands. Conversely, electric drives excel in indoor, noise-sensitive environments, making them ideal for warehouses.

Mechanical and pneumatic drives offer cost-effective, reliable solutions particularly suited to outdoor or high-cycling applications such as port handling. The key is aligning your core needs — weight capacity, safety, workflow speed, and maintenance budgets — with the clamp system that fits best.

Let heavy plate handling become effortless and safe — say goodbye to manual risks, and welcome the era of intelligent operation.