In the realm of industrial steel plate handling, safety and efficiency are of paramount importance. Traditional handling tools, such as conventional clamps, have long been associated with significant drawbacks, including instability, jamming, and a lack of precision. These issues not only pose serious safety risks but also lead to reduced productivity and increased operational costs. In this article, we will delve into the advanced transmission mechanism of the translational slab clamp and contrast it with traditional counterparts, highlighting its ability to eliminate the common problems of shaking and jamming.

Let's start by examining some real - world cases. In a steel mill, a traditional clamp malfunctioned during the handling of a large steel plate. The shaking and jamming of the clamp caused the steel plate to fall, resulting in a significant safety incident and halting production for several hours. Similar scenarios occur frequently in ports and metal processing workshops, where traditional clamps struggle to provide a stable and reliable solution for steel plate handling.

The root cause of these problems lies in the design of traditional gear or hydraulic systems. These systems often suffer from issues such as backlash, leakage, and wear, which lead to imprecise control and unstable operation. For example, in a traditional hydraulic clamp, hydraulic fluid leakage can cause a loss of clamping force, while gear systems may experience tooth wear and breakage over time.

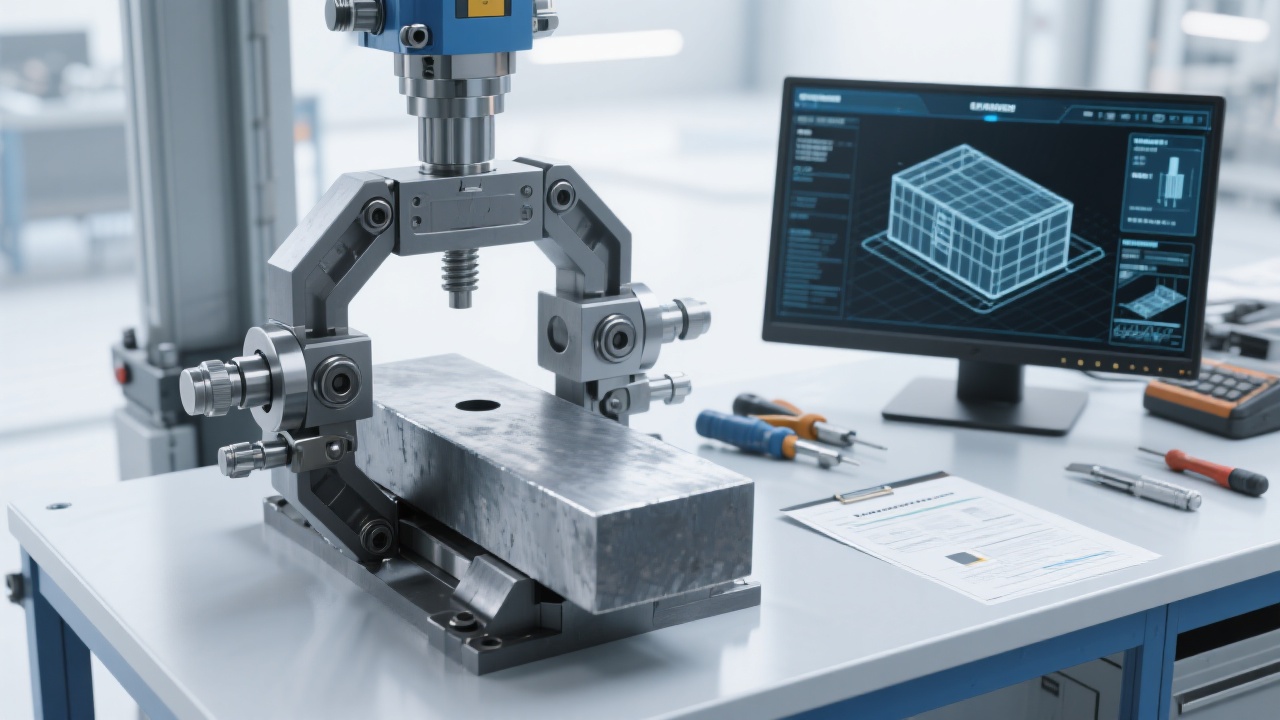

The translational slab clamp features an innovative transmission mechanism that offers superior stability and precise control. Unlike traditional systems, this mechanism is designed to minimize backlash and ensure smooth operation. It uses a combination of high - precision bearings and advanced linkages to translate the input motion into a stable and accurate clamping action.

When compared to traditional gear systems, the new mechanism reduces the risk of tooth wear and breakage by up to 80%. In addition, it eliminates hydraulic fluid leakage issues, providing a more reliable and maintenance - free solution. This results in a significant improvement in the overall safety and efficiency of steel plate handling operations.

The structural design of the translational slab clamp is another key factor contributing to its long - term stability. It is constructed using high - strength alloy materials that can withstand heavy loads and harsh working environments. The clamp has a service life of up to 10 years under normal operating conditions, which is significantly longer than that of traditional clamps.

The use of advanced manufacturing techniques ensures that the clamp maintains its structural integrity even after repeated use. For example, the welding joints are designed to have high fatigue resistance, and the surface treatment provides excellent corrosion protection.

The translational slab clamp is suitable for a wide range of applications, including continuous casting, port loading and unloading, and warehouse stacking. In continuous casting, the clamp's precise control allows for accurate positioning of steel slabs, improving the quality of the casting process. In port operations, it can handle large - scale steel plate handling tasks with ease, reducing the time required for loading and unloading.

In a port, after replacing traditional clamps with translational slab clamps, the loading and unloading efficiency increased by 30%. In a metal processing workshop, the use of these clamps reduced the number of safety incidents by 50% and improved overall productivity by 25%.

The translational slab clamp represents a significant advancement in industrial steel plate handling technology. Its advanced transmission mechanism, combined with its high - strength structure and multi - scenario applicability, provides a comprehensive solution for the problems associated with traditional handling tools. By choosing the translational slab clamp, you can say goodbye to the shaking and jamming of traditional clamps, significantly enhance the safety and efficiency of your operations, and make it an essential tool for modern industrial steel plate handling.

If you are interested in learning more about the details of this product or obtaining technical support, please click here.