The power-driven steel plate clamp is a remarkable innovation in the field of heavy - industry logistics. It is crafted from high - strength alloy steel, which provides exceptional durability. This material can withstand extreme forces and harsh environments, ensuring a long service life. For instance, in a large - scale steel plant in Germany, the clamps made of this alloy steel have been in use for over 10 years with minimal wear and tear.

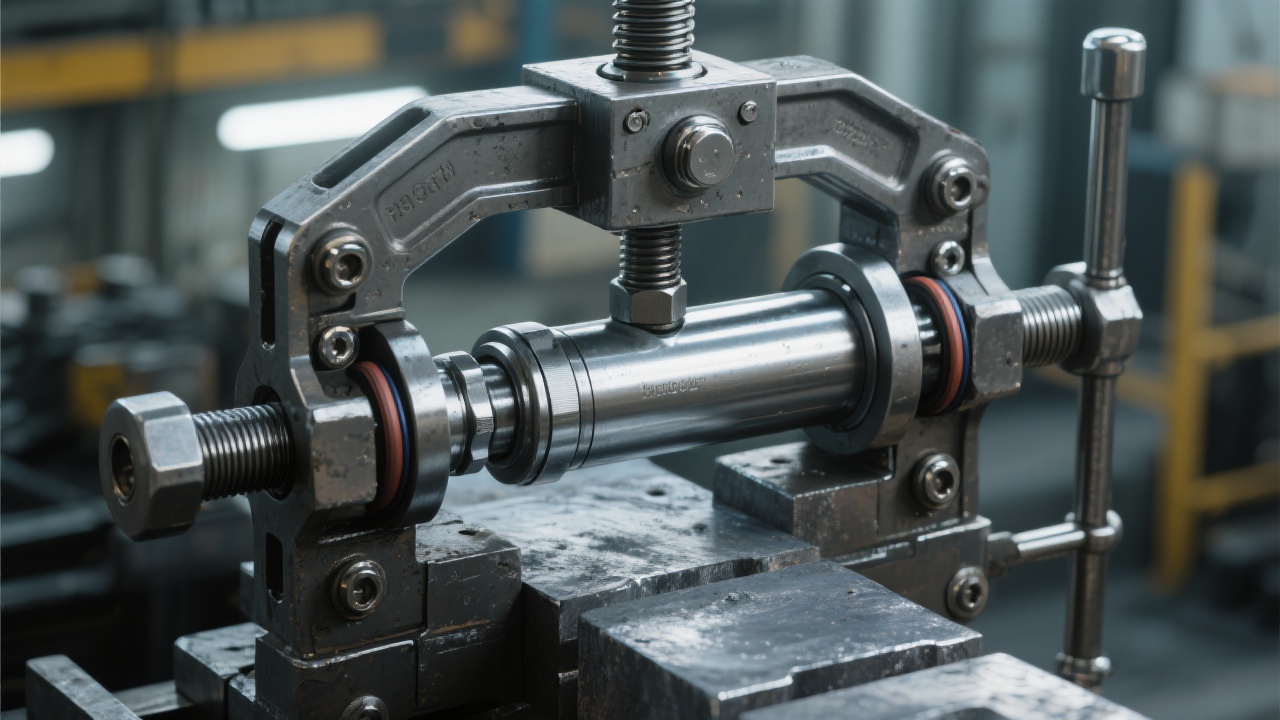

The core driving mechanism of the clamp is hydraulic. The hydraulic system allows for precise control of the clamping force. It can adjust the force according to the weight and size of the steel plates, ensuring a secure grip. In fact, industry data shows that the use of hydraulic - driven clamps can increase the efficiency of steel plate handling by up to 30% compared to traditional mechanical clamps.

The hydraulic drive offers several key advantages. Firstly, it provides smooth and stable operation. The continuous and adjustable force output reduces the risk of sudden shocks that could damage the steel plates or the equipment. Secondly, it is highly responsive. The operator can quickly adjust the clamping force as needed, which is crucial when dealing with different types of steel plates.

The automatic switch function is another highlight. It enables the clamp to open and close automatically, eliminating the need for manual intervention. This not only improves efficiency but also enhances safety. In a hot - rolling mill in Japan, the automatic switch function has reduced the accident rate during steel plate handling by 25%.

In steel plants, the power - driven steel plate clamp is used for moving large - sized steel plates from one production stage to another. It can handle high - temperature steel plates directly from the casting process. The high - strength alloy steel and the reliable hydraulic system ensure that the clamps can operate in high - temperature environments without deformation or failure.

Hot - rolling mills require precise handling of hot steel plates. The clamp's hydraulic drive and automatic switch function allow for quick and accurate positioning of the plates. This improves the overall rolling process efficiency and reduces the time between operations.

Logistics centers need to handle a large volume of steel plates daily. The power - driven steel plate clamp can significantly increase the loading and unloading speed. Its automatic operation reduces the labor intensity and the time required for each handling task.

In the high - temperature steel plate handling process, there are many safety risks, such as high - temperature burns, unstable clamping, and potential dropping of the plates. The power - driven steel plate clamp addresses these issues effectively. The high - strength alloy steel and the hydraulic system ensure stable clamping, and the automatic switch function reduces the chances of human error.

Are you facing similar safety and efficiency challenges in your steel handling operations? Share your experiences and let's discuss how the power - driven steel plate clamp can benefit your business.

Discover More About Our Power - Driven Steel Plate Clamps and Request a Trial!