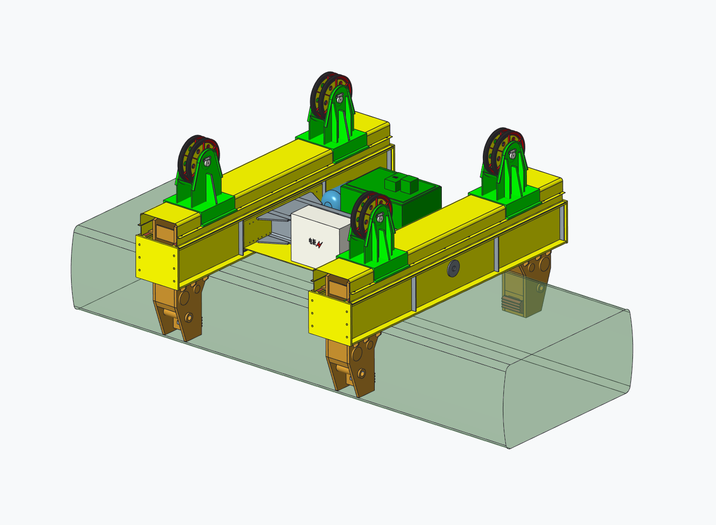

High - efficiency power - type steel plate clamps are key lifting tools in the steel industry. They are equipped with advanced hydraulic drive systems. This hydraulic drive enables the clamps to generate strong clamping force, which can reach up to 80% more than traditional mechanical clamps, ensuring a firm grip on steel plates. The automatic switch function allows the clamps to quickly adjust their clamping state according to the operation requirements, reducing manual intervention and improving operational efficiency.

These clamps are made of high - strength alloy materials. Compared with ordinary steel materials, the high - strength alloy can increase the service life of the clamps by 50%. It can withstand high - intensity use in high - temperature environments, making them ideal for various steel production scenarios.

In steel production facilities, the demand is to handle large - scale steel plates efficiently. The high - efficiency power - type steel plate clamps can quickly move steel plates between different production stations. For example, they can complete the transfer of a 2 - ton steel plate within 3 minutes, which is 2 minutes faster than traditional clamps, greatly improving the overall production rhythm.

Hot - rolling mills deal with high - temperature steel plates. The high - temperature resistance of these clamps ensures stable operation. They can operate continuously for 8 hours in an environment of 500°C without performance degradation, effectively meeting the long - term production needs of hot - rolling mills.

Logistics centers need to handle steel plates of various sizes and weights. The adjustable clamping force of the high - efficiency power - type steel plate clamps allows them to adapt to different steel plates. They can improve the loading and unloading efficiency of steel plates in logistics centers by 40%, reducing the waiting time of trucks and improving the turnover rate of goods.

In cold - rolling steel mills, precision handling is required. The automatic switch function of the clamps can accurately control the clamping and releasing of steel plates, ensuring the quality of cold - rolling products. They can reduce the error rate of steel plate handling in cold - rolling mills from 5% to 1%.

Continuous casting workshops require high - speed and continuous steel plate handling. The high - efficiency power - type steel plate clamps can keep up with the continuous casting speed, transporting steel plates in a timely manner. They can increase the production efficiency of continuous casting workshops by 30%.

A large steel company introduced high - efficiency power - type steel plate clamps in its hot - rolling mill. Before using these clamps, the production line could process 100 tons of steel plates per day, and the accident rate was 3%. After using the clamps, the daily production increased to 130 tons, and the accident rate dropped to 1%. These data clearly show that the clamps can significantly improve production efficiency and reduce risks.

The design of these clamps greatly contributes to safety. The automatic locking mechanism ensures that the steel plates will not fall off during transportation, reducing the potential safety hazards. The ergonomic design also makes the operation more convenient. Workers can operate the clamps with less physical effort, improving their work comfort.

To better promote the high - efficiency power - type steel plate clamps, we use multi - channel marketing methods. Through our website, we provide detailed product information, including product features, application scenarios, and real - world cases. We also encourage customers to leave comments in the message area and answer their common questions in a timely manner, enhancing the user experience.

If you want to learn more about how high - efficiency power - type steel plate clamps can improve your steel production efficiency, ensure safety, and adapt to various scenarios, click here to get detailed product information and start your journey to production optimization!