Industrial handling processes often face several challenges. Traditional methods of handling heavy steel coils are typically complex, requiring a significant amount of manual labor and time. Moreover, there is a high risk of damage to the steel coils during the handling process, which can lead to product quality issues and increased costs. For example, in some factories, the damage rate of steel coils during handling can reach up to 5%, resulting in substantial financial losses.

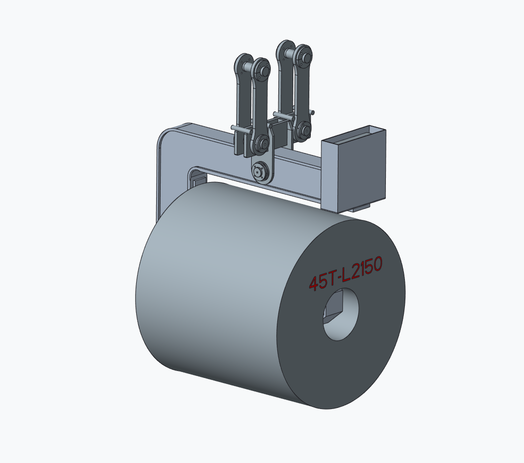

This is where the heavy-duty steel coil clamp, a type of roll clamp, comes into play. It offers innovative solutions to these long - standing problems, revolutionizing the way industrial handling is carried out.

The gravity - operated mechanism of this heavy - duty steel coil clamp is a game - changer. Unlike traditional clamps that rely on complex hydraulic or electrical systems, this clamp uses the force of gravity to secure the steel coil. When the clamp is lowered onto the coil, the weight of the coil activates the clamping mechanism, ensuring a firm and secure grip. This not only simplifies the operation process but also reduces the risk of mechanical failures. In fact, with this gravity - operated design, the maintenance frequency of the clamp can be reduced by up to 30% compared to traditional clamps.

The adjustable support device is another remarkable feature. Steel coils come in various sizes and shapes, and traditional clamps may not be able to adapt to these variations effectively. However, this heavy - duty steel coil clamp is equipped with an adjustable support device that can be customized according to the specific dimensions of the coil. This ensures that the coil is evenly supported during the handling process, reducing the risk of deformation. In a recent case study, a company using this clamp reported a 40% reduction in coil deformation compared to their previous handling methods.

To further protect the steel coils from damage, the clamp is lined with a protective filling material. This material acts as a buffer between the clamp and the coil, preventing scratches and dents. It is especially useful for high - quality steel coils where even minor surface damage can affect the final product quality. With the use of this protective filling material, the surface damage rate of steel coils during handling can be reduced to less than 1%.

The combination of these innovative designs significantly improves the quality and efficiency of industrial handling. The simplified operation process allows workers to handle steel coils more quickly, reducing the overall handling time. For example, in a large - scale steel manufacturing plant, the use of this heavy - duty steel coil clamp has increased the handling efficiency by 50%, enabling the plant to process more orders in a shorter period.

In addition, the reduced damage rate means that fewer steel coils need to be reworked or discarded, resulting in cost savings and improved product quality. This directly impacts the bottom line of the business, making it a more profitable operation.

Safety is a top priority in industrial handling. This heavy - duty steel coil clamp is designed with multiple safety features. The gravity - operated mechanism ensures that the clamp remains securely attached to the coil, even in the event of a power failure. The adjustable support device and protective filling material also contribute to the safety of the handling process by reducing the risk of coil slippage and damage.

From a user experience perspective, the clamp is easy to operate and maintain. Workers can quickly learn how to use the clamp, and the reduced maintenance requirements mean less downtime for the equipment.

Several companies have already benefited from using this heavy - duty steel coil clamp. A steel processing company in Europe reported a 60% reduction in handling costs and a 35% increase in productivity after implementing this clamp. Another company in Asia was able to improve its product quality significantly, leading to an increase in customer satisfaction and repeat business.

This heavy - duty steel coil clamp is an ideal choice for any steel coil lifting task. It offers innovative solutions to the common problems in industrial handling, improving both the quality and efficiency of the process. With its safety features and excellent user experience, it is a valuable investment for any industrial business.

This heavy - duty steel coil clamp is the perfect choice for any steel coil lifting task, bringing a brand - new experience to your industrial handling. Come and learn more!