In the fast - paced automotive industry, enhancing production efficiency and ensuring safety are top priorities. Traditional lifting tools have long been a headache for manufacturers. They are often heavy, bulky, and lack the flexibility to adapt to different components. For example, in an old - fashioned car factory, workers had to struggle with a large, inflexible lifting device to move car engines. It not only took a long time to set up but also posed a high risk of accidents due to its poor stability.

However, the automotive production line multi - functional lifting tool is here to revolutionize the game. This tool is made of high - strength lightweight materials, which is not only compact but also extremely durable. The use of these advanced materials reduces the weight of the lifting tool by up to 30% compared to traditional ones, while maintaining high strength. As shown in the following information chart:

| Lifting Tool Type | Weight | Strength |

|---|---|---|

| Traditional | Heavy | Standard |

| New Multi - functional | 30% lighter | High |

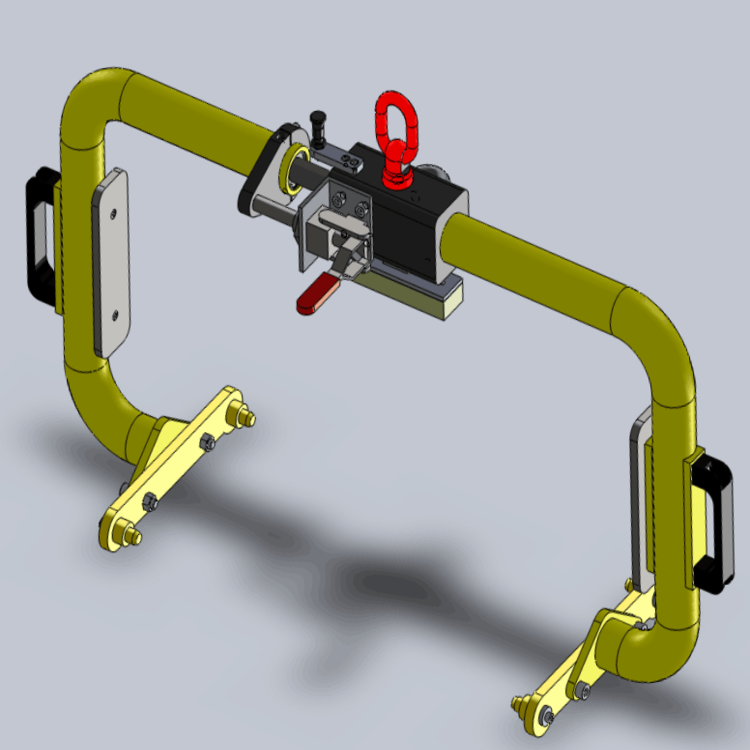

The unique clamping mechanism of this lifting tool is truly remarkable. It can firmly hold different automotive components, from small parts to large body panels. The adjustable function allows it to adapt to various shapes and sizes. For instance, it can easily adjust its clamping force and width to fit a car door or a transmission. Check out this amazing tool in action in the picture below:

In the automotive manufacturing process, this multi - functional lifting tool significantly improves efficiency. A study shows that it can reduce the time required for component handling by up to 40%. In addition, it greatly enhances safety. With its stable clamping and lightweight design, the risk of accidents during lifting operations is reduced by 50%. Many users have left positive feedback. One car manufacturer said, "This lifting tool has changed our production process. It's so easy to use and has saved us a lot of time and money."

This tool is not only suitable for automotive manufacturing but also for automotive repair and maintenance. In a repair shop, mechanics can use it to lift engines or other heavy parts with ease, reducing their labor intensity and improving work quality.

The introduction of this multi - functional lifting tool has a profound impact on the automotive industry. It promotes the development of the industry by improving production efficiency, reducing costs, and enhancing safety. In the future, we can expect to see it widely used in more automotive production lines and repair shops around the world.

"The automotive production line multi - functional lifting tool is a key innovation that will shape the future of the automotive industry." - Industry Expert

In conclusion, the automotive production line multi - functional lifting tool, with its high - strength lightweight materials, unique clamping mechanism, and adjustable function, is a revolutionary product. It not only improves production efficiency and safety but also has a positive impact on the sustainable development of the automotive industry.

Don't miss out on this amazing product! Come and visit our website to learn more about this high - efficiency solution for the automotive industry. Contact us at [Contact Information] for further details.