In industrial handling operations, many companies face a series of challenges. Complex operation processes often require a large amount of labor and time. For example, in traditional steel coil handling, workers need to spend an average of 30 minutes per operation to adjust the lifting equipment, which not only reduces work efficiency but also increases labor costs. Moreover, steel coils are easily damaged during handling. Statistics show that about 15% of steel coils are damaged to some extent during the handling process, resulting in significant economic losses for enterprises.

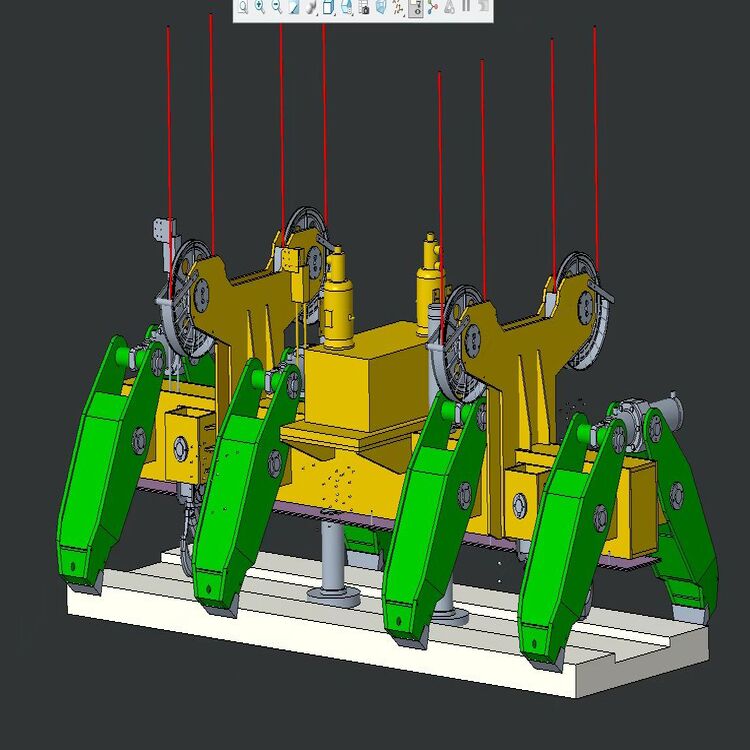

This heavy - duty steel coil clamp adopts a gravity - operated mechanism. Unlike traditional lifting equipment that requires complex power systems and control operations, this mechanism uses the weight of the steel coil itself to achieve automatic clamping. Once the clamp is placed on the steel coil, the gravity of the coil activates the clamping device, ensuring a firm grip. This simplifies the operation process and reduces the risk of human - error, increasing the safety and efficiency of handling.

The support device of the clamp can be adjusted according to different coil diameters. Whether it is a small - diameter steel coil with a diameter of 500mm or a large - diameter one of 2000mm, the clamp can provide stable support. This flexibility makes the clamp suitable for a wide range of steel coils, increasing its versatility and applicability in different industrial scenarios.

To prevent damage to the steel coil surface, the clamp is equipped with a protective filling material. This material can effectively buffer the pressure between the clamp and the steel coil, reducing scratches and dents. In practical applications, after using this clamp, the damage rate of steel coils during handling has been reduced to less than 3%, greatly improving the quality of the steel coils after handling.

The innovative design of this heavy - duty steel coil clamp has significantly improved industrial handling quality and efficiency. Firstly, it has increased productivity. The simplified operation process allows workers to complete a handling task in an average of 10 minutes, which is three times faster than the traditional method. Secondly, the adjustable support device and wide applicability increase the flexibility of the clamp, enabling it to be used in various industrial fields such as steel mills, non - ferrous metal processing, heavy machinery manufacturing, and metallurgical plants. Thirdly, by reducing the damage rate of steel coils and labor costs, the overall handling cost has been reduced by about 20%.

The clamp has a high - level safety design. The gravity - operated mechanism ensures that the clamp will not accidentally release during handling, and the protective filling material also reduces the risk of injury to workers. Many operators have given positive feedback on its user - friendliness. For example, an operator from a steel mill said, "This clamp is very easy to operate. I don't need to worry about complex control systems anymore, and it can protect the steel coils well."

In a large - scale steel mill, after using this heavy - duty steel coil clamp, the monthly handling volume of steel coils has increased from 5000 tons to 7000 tons, a growth rate of 40%. At the same time, the damage rate of steel coils has decreased from 15% to 2%. In a non - ferrous metal processing plant, the clamp has also improved the handling efficiency by 35% and reduced the cost by 18%. These data fully demonstrate the advantages of this product.

This heavy - duty steel coil clamp is an ideal choice for industrial handling, which can bring significant benefits to your enterprise. With its innovative design, high - efficiency performance, and user - friendly features, it can effectively solve the pain points in industrial handling. If you want to improve your industrial handling efficiency and quality, don't miss this excellent solution. Click here to learn more about this heavy - duty steel coil clamp and take the first step towards a more efficient industrial handling process!