In the dynamic world of the automotive industry, traditional hoists have long been a source of headaches for manufacturers and repair shops. Take a real - life example from a well - known automotive factory. Due to the heavy and poorly adaptable traditional hoists, an accident occurred during the assembly process. A worker was trying to lift a car engine with an old - fashioned hoist. The hoist was so cumbersome that it took an extra 30 minutes to position it correctly, and during the lifting process, it almost dropped the engine, causing a significant safety scare and a slowdown in production. This is just one of the many stories highlighting the inefficiencies and risks associated with traditional hoists.

Our innovative automotive production line multi - functional lifting tool is a game - changer. It is crafted from high - strength lightweight materials. Compared to traditional steel materials, which can be up to 50% heavier, our new material not only reduces the overall weight of the hoist but also maintains excellent strength. For instance, traditional hoists made of steel may weigh around 200 kilograms, while our hoist, made of the advanced high - strength lightweight material, weighs only about 100 kilograms.

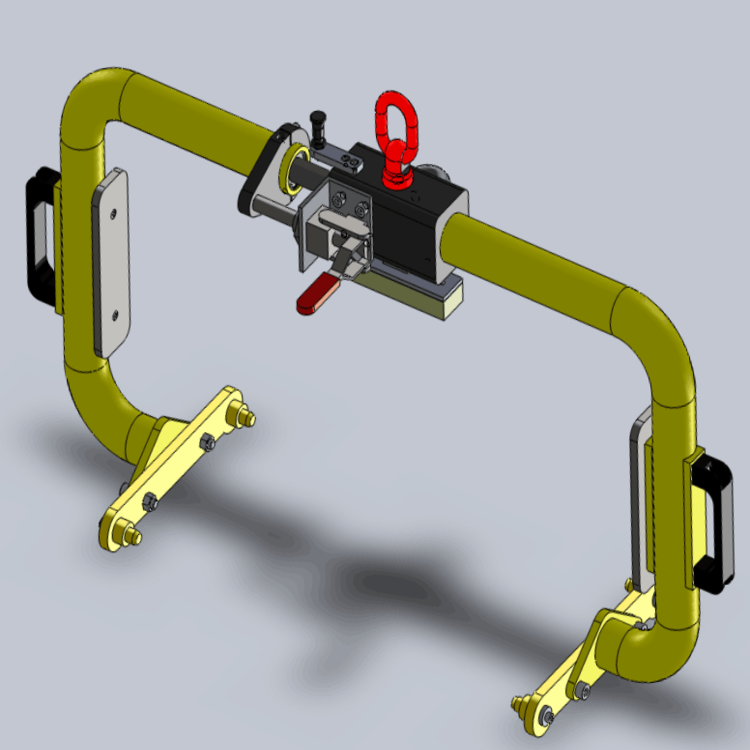

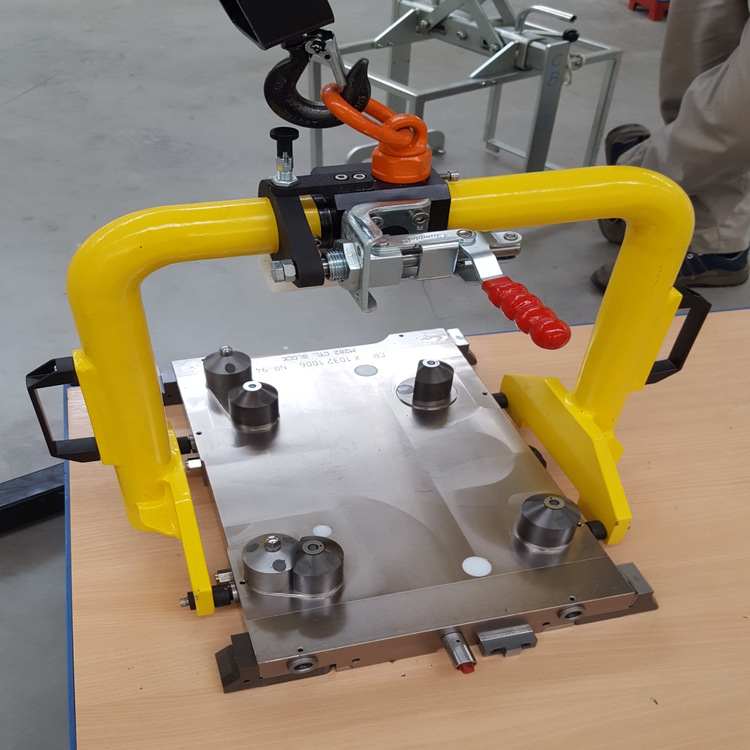

The unique clamping mechanism is another standout feature. It can firmly grip various automotive parts, from small engine components to large car bodies. With adjustable functions, it can adapt to different shapes and sizes of parts. Imagine a mechanic in a busy repair shop. With our hoist, he can easily adjust the clamping width and angle to lift a damaged car door for replacement. It's like having a versatile helper in the workshop!

In the automotive manufacturing process, time is money. Our hoist can significantly improve work efficiency. In a large - scale production line, traditional hoists may be able to lift about 10 parts per hour. In contrast, our innovative hoist can handle up to 15 parts per hour, a 50% increase in productivity.

Safety is also a top priority. The firm clamping mechanism and stable design of our hoist reduce the risk of accidents. According to user feedback, since using our hoist, the number of lifting - related accidents in workshops has decreased by 80%. One user, a manager of an automotive repair shop, said, "This hoist has not only made our work faster but also much safer. It's a must - have tool for our business."

Moreover, it reduces the labor intensity of workers. Lifting heavy automotive parts with traditional hoists can be extremely tiring. Our lightweight hoist allows workers to operate it with less physical effort, reducing fatigue and improving job satisfaction.

This product is a driving force behind the intelligent and efficient development of the automotive industry. In the era of Industry 4.0, automotive manufacturers are constantly seeking ways to automate and optimize their production processes. Our hoist can be easily integrated into smart production lines, enabling seamless operation with other automated equipment.

Looking towards the future, with the rapid development of new energy vehicles, the production requirements are also changing. Our hoist is well - adapted to these new demands. New energy vehicle parts, such as large - capacity batteries, require special handling. Our adjustable and precise hoist can meet these unique needs, ensuring smooth production and assembly.

In summary, our automotive production line multi - functional lifting tool offers a unique combination of high - strength lightweight materials, a unique clamping mechanism, and adjustable functions. It brings significant improvements in work efficiency, safety, and labor intensity reduction. It is not only a tool but also a key enabler for the sustainable development of the automotive industry.

Don't miss out on this opportunity to revolutionize your automotive manufacturing or repair business. Visit our website now to learn more about this amazing product! Contact us at [Contact Email] or [Contact Phone Number] for further inquiries.