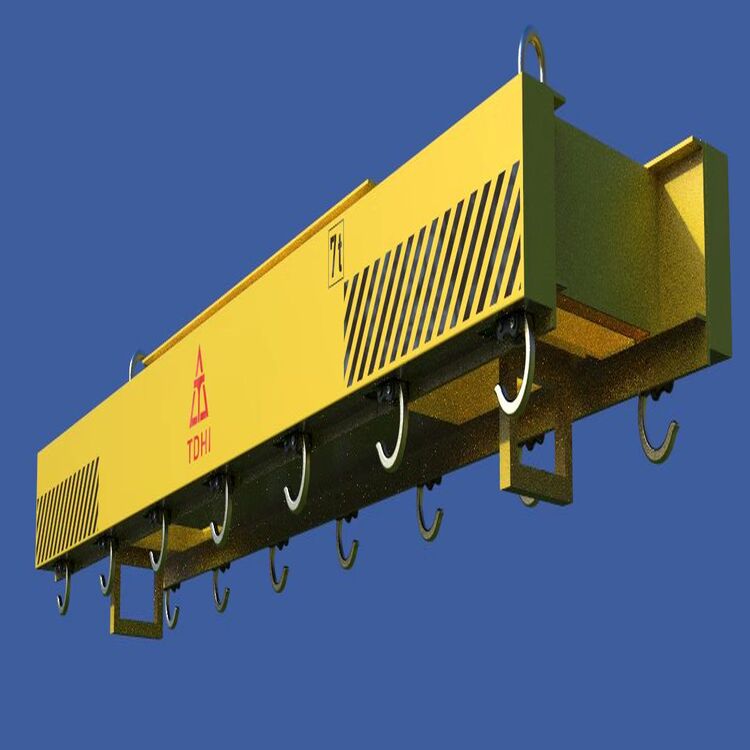

Missing out on this aerial heavy - load lifting release beam means missing a qualitative leap in multi - domain lifting operations. This innovative tool is specifically designed for high - altitude work and special lifting scenarios, promising to revolutionize the way you handle heavy loads.

In a large - scale construction project, a traditional lifting device struggled to precisely position a 5 - ton pre - fabricated concrete component at a height of 80 meters. The process was not only time - consuming but also fraught with safety risks. This is where the aerial heavy - load lifting release beam steps in as a savior.

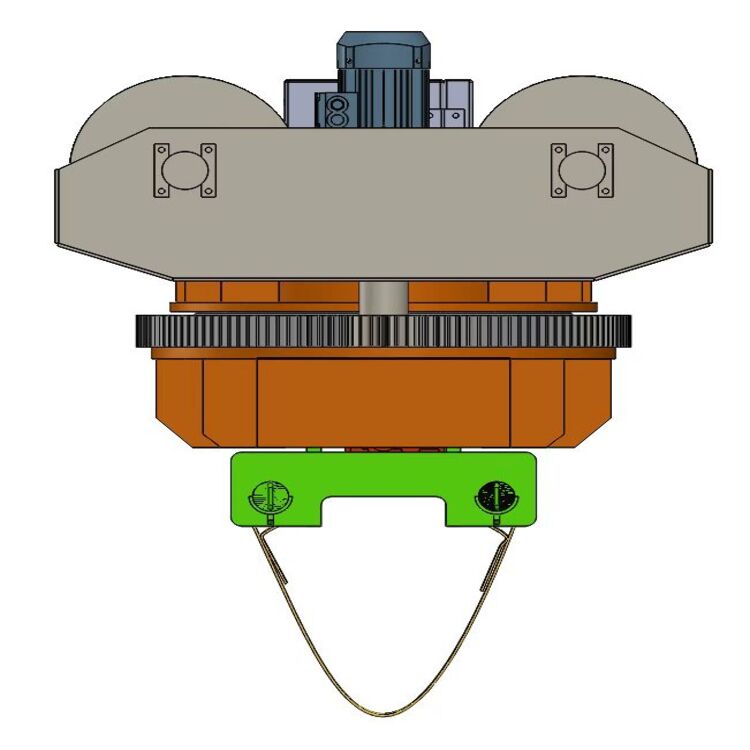

This product combines advanced technology with strict safety principles. It is made of high - strength, lightweight alloy materials, which reduce the overall weight of the beam by up to 30% compared to traditional steel beams, while maintaining a high load - bearing capacity of up to 10 tons. For instance, in laboratory tests, the beam withstood forces up to 120% of its rated capacity without any signs of deformation.

With a compact design, it takes up 20% less space than similar products in the market, making it ideal for confined spaces in high - altitude operations. The operation is extremely simple. A single operator can control the release process with just a few button presses, reducing the need for a large and complex operation team. In fact, field tests have shown that the operation time can be reduced by 40%.

Mining Industry: In a large gold mine, the traditional lifting equipment was inefficient in transporting heavy mining machinery to deep underground shafts. After using the aerial heavy - load lifting release beam, the lifting time was reduced from 3 hours to 1.5 hours per operation, and the safety incidents related to lifting were reduced by 60%.

Chemical Industry: In chemical plants, the precise installation of large - scale reaction vessels is crucial. This beam enables accurate positioning with an error margin of less than 5 millimeters, which is far superior to the previous 20 - millimeter error of traditional methods. It also ensures the safety of workers during the installation process in potentially hazardous environments.

Construction Industry: As mentioned in the previous case, it significantly improves the efficiency of high - altitude component installation. In a high - rise building project, the use of this beam accelerated the construction progress by 20%.

Logistics and Warehousing: In large logistics warehouses, the beam can quickly and accurately transfer heavy goods between different storage levels. For example, it can increase the daily handling capacity of heavy - duty goods by 30%.

Maintenance and Repair: When maintaining large - scale equipment such as bridges and wind turbines, the beam's lightweight and easy - to - operate features make it possible to complete maintenance tasks more quickly. In a bridge maintenance project, the use of this beam reduced the maintenance time by 25%.

Compared with other products in the market, this aerial heavy - load lifting release beam has obvious advantages. Other products may have lower load - bearing capacities, more complex operation processes, and larger sizes. Our product's high - strength materials, simple operation, and compact design make it a clear winner.

This product can bring a new height to the lifting work of various industries. Don't miss out on this opportunity for a qualitative leap in your multi - domain lifting operations. If you want to learn more about this aerial heavy - load lifting release beam or have any inquiries, please contact our company. Our professional team is ready to provide you with detailed information and support.