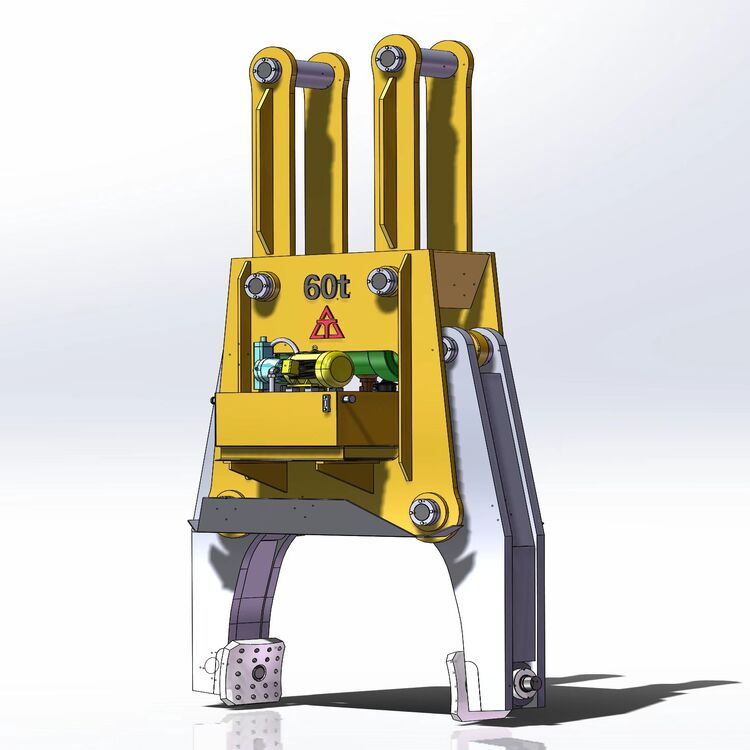

Powered steel ingot clamps are specifically designed for the steel industry. They are driven by a hydraulic system, which provides a reliable and efficient way to handle steel ingots. These clamps have a wide range of load - bearing capacities, typically from 8 tons to 550 tons, making them suitable for various steel - handling tasks.

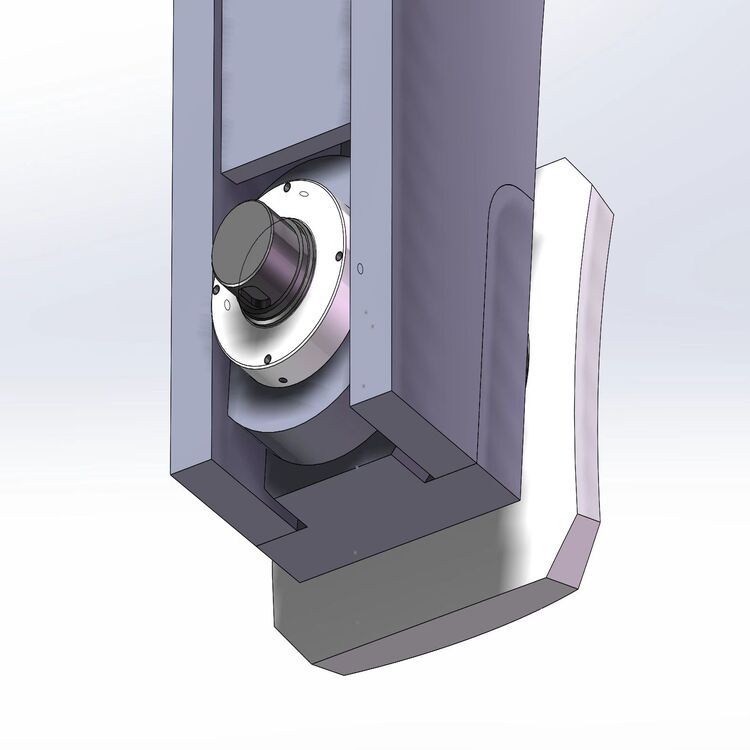

The hydraulic - driven automatic clamping mechanism is a key safety feature of these clamps. Once the clamp is positioned around the steel ingot, the hydraulic system automatically engages, ensuring a firm and secure grip. This reduces the risk of the ingot slipping during handling, which is a major safety concern in steel enterprises.

Powered steel ingot clamps are engineered to meet or exceed strict international safety standards. They undergo rigorous testing and quality control processes to ensure their reliability and safety. For example, in a large - scale steel plant in Europe, after replacing traditional clamps with powered steel ingot clamps, the number of safety accidents related to ingot handling decreased by 70% within a year.

The operation of these clamps is intuitive and straightforward. Workers can quickly master the operation skills, which significantly reduces the training time. In a steel production line in Asia, the use of powered steel ingot clamps increased the daily handling efficiency of steel ingots by 30% due to the simple operation.

The compact design of the clamps allows them to operate in limited spaces. They can be easily integrated into existing steel production lines and transportation systems, which simplifies the overall handling process. This not only saves space but also improves the overall efficiency of the steel - handling operations.

Powered steel ingot clamps are versatile and can be used in various scenarios. They are commonly used in steel production lines for transferring steel ingots from one process to another. In heavy - casting transportation, these clamps can safely and efficiently load and unload large - scale steel ingots. They are also suitable for steel storage yards, where they can quickly organize and relocate steel ingots.

In the highly competitive steel industry, safety and efficiency are crucial factors for enterprises. Powered steel ingot clamps can effectively solve the safety and efficiency problems faced by steel enterprises. By reducing safety risks and improving handling efficiency, enterprises can lower production costs, increase productivity, and enhance their market competitiveness. For instance, a steel company in North America improved its overall production efficiency by 25% after adopting powered steel ingot clamps, which helped it gain a larger market share.

Powered steel ingot clamps are the essential choice for steel enterprises to enhance their industry competitiveness. They can effectively solve the safety and efficiency problems in the steel - handling process. Don't miss this opportunity to transform your steel - handling operations!

Contact Us Now