In the highly competitive steel production industry, enhancing efficiency is crucial for enterprises to gain a competitive edge. The high-efficiency power-type steel plate clamp emerges as the perfect solution for improving steel production efficiency. This innovative clamp offers a range of remarkable features that can significantly optimize the steel production process.

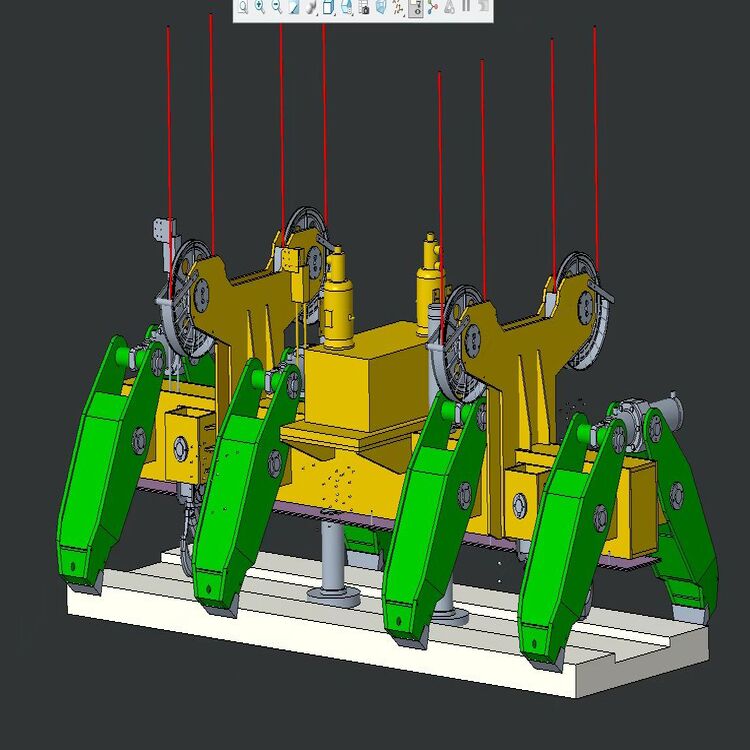

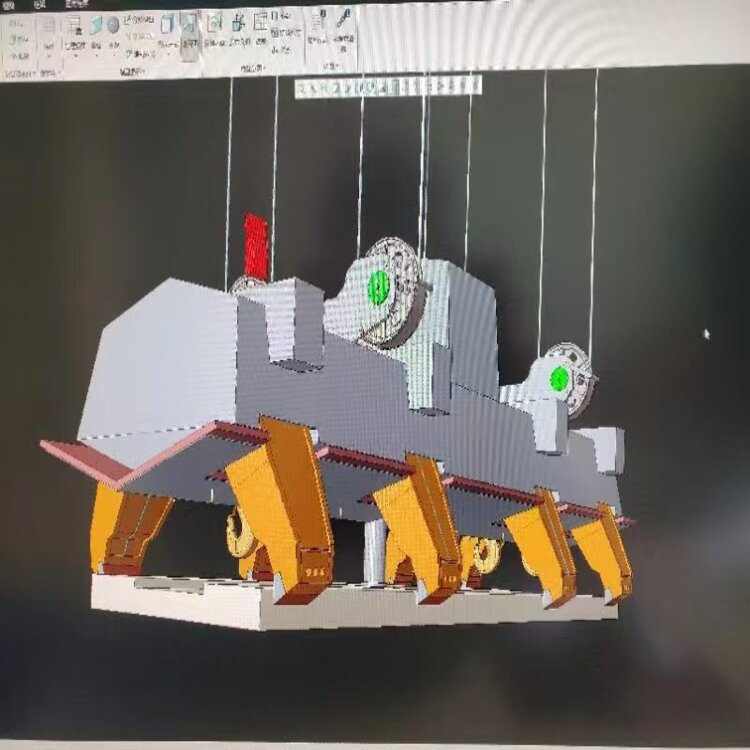

One of the key features of these clamps is their hydraulic drive mechanism. This advanced technology enables precise movement and adjustable clamping force. With a precision of up to ±0.5 degrees in movement, it ensures that steel plates can be accurately positioned during handling. The adjustable clamping force, which can range from 5 tons to 20 tons depending on the model, allows the clamp to adapt to different sizes and weights of steel plates, providing a secure grip.

These clamps are highly versatile and can be applied in various steel production scenarios. In steel production facilities, they have been proven to reduce the handling time of steel plates by up to 30%. In hot rolling mills, where high temperatures are a challenge, the clamps are designed to withstand temperatures up to 800°C, ensuring the safe and efficient handling of hot steel plates. In continuous casting workshops, the automatic opening and closing function of the clamps reduces the need for manual intervention, thereby lowering the operational risk. In cold rolling steel plants, the clamps help to improve the accuracy of plate stacking, increasing the overall production efficiency by approximately 25%.

When compared with traditional clamps, high-efficiency power-type steel plate clamps offer several significant advantages. Traditional clamps often have limited clamping force and poor precision, which can lead to unstable handling and potential safety hazards. In contrast, the new clamps provide adjustable clamping force and precise movement, ensuring a more reliable and efficient operation. Moreover, traditional clamps usually require more manual labor, while the automatic features of the new clamps reduce the labor intensity and improve the overall productivity.

Industry experts point out that the technical principle of high-efficiency power-type steel plate clamps is based on the combination of hydraulic technology and intelligent control systems. This integration allows for more precise and efficient operation. In terms of development trends, experts predict that these clamps will become more intelligent and automated in the future, with features such as real-time monitoring and remote control.

Many steel enterprises have already benefited from using high-efficiency power-type steel plate clamps. For example, a large steel mill in [Region] reported a 28% increase in overall production efficiency after replacing traditional clamps with these new ones. The reduction in production delays also led to significant cost savings.

In conclusion, high-efficiency power-type steel plate clamps are indeed the perfect solution for boosting steel production efficiency. They offer a combination of advanced technology, versatility, and safety, which can bring high - efficiency production and competitive advantages to steel enterprises.

Are you looking to improve your steel production efficiency? Contact us now to learn more about how our high - efficiency power - type steel plate clamps can transform your production process!