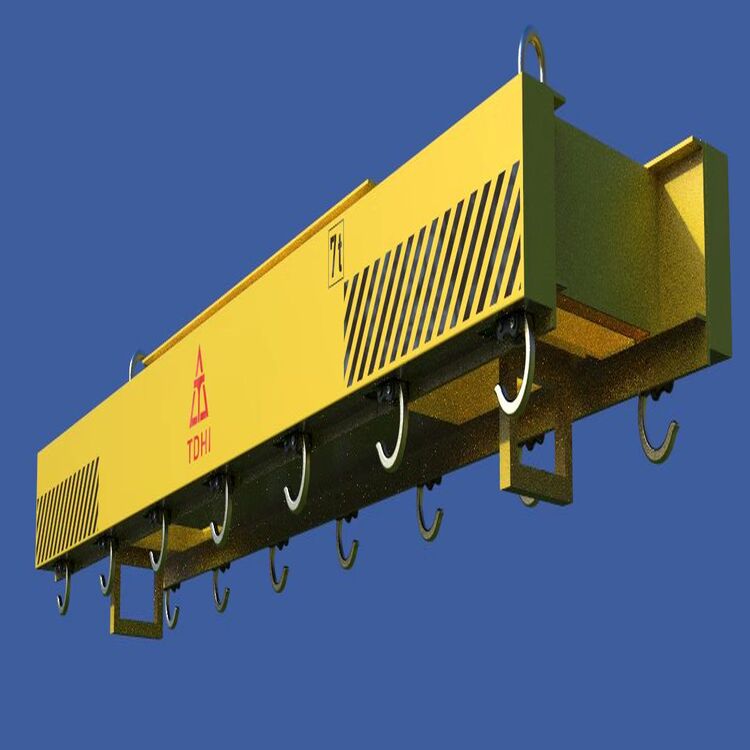

In the realm of high - altitude heavy load lifting operations, challenges are numerous. For instance, in a large - scale bridge construction project, the engineers faced the daunting task of lifting heavy steel girders to a height of over 80 meters. Traditional lifting methods were not only time - consuming but also posed significant safety risks. This is where the high - altitude heavy load lifting release beam comes into play, offering a revolutionary solution to such problems.

The high - altitude heavy load lifting release beam is designed with several advanced technologies. Firstly, it adopts a unique hydraulic control system. This system can precisely control the release process, with an accuracy of up to ±0.1 seconds in the release time. For example, in a mining operation where the release of heavy equipment at a specific time is crucial, this hydraulic control system ensures seamless and safe operations.

Secondly, the product is made of high - strength and lightweight materials. Carbon fiber - reinforced composites are used, which reduce the weight of the beam by 30% compared to traditional steel beams, while maintaining a high strength - to - weight ratio. Tests have shown that these beams can withstand a maximum load of up to 500 tons, making them suitable for a wide range of heavy - load lifting tasks.

Mining Industry: In a large open - pit mine, the high - altitude heavy load lifting release beam is used to lift large - scale mining equipment such as crushers and conveyors. By using this beam, the lifting time has been reduced by 40%, and the safety of the operation has been significantly improved. This not only increases the efficiency of mining operations but also reduces the risk of accidents.

Chemical Industry: In chemical plants, the installation and maintenance of large - scale reaction vessels often require high - altitude lifting. The high - altitude heavy load lifting release beam can ensure the precise placement of these vessels, reducing the damage rate during installation from 5% to less than 1%. This not only saves costs but also ensures the normal operation of the chemical plant.

Construction Industry: As mentioned earlier, in bridge construction, the beam enables the safe and efficient lifting of heavy steel girders. In a high - rise building construction project, it can also be used to lift pre - fabricated building components, accelerating the construction progress by 30%.

Logistics and Warehousing: For the handling of large - scale goods in warehouses, the high - altitude heavy load lifting release beam can quickly and accurately lift and place goods, increasing the handling efficiency by 50%.

Maintenance and Repair: In the maintenance of power transmission towers, the beam can safely lift maintenance equipment to the required height, reducing the maintenance time by 25%.

Compared with similar products in the market, the high - altitude heavy load lifting release beam has obvious advantages. Other products may lack the precise hydraulic control system, resulting in inaccurate release times. In terms of materials, traditional products are often heavier, which limits their application scope. Our product's high - strength and lightweight design, combined with advanced control technology, make it stand out in the market.

If you are involved in industries such as mining, chemical, construction, logistics, or maintenance, and are facing challenges in high - altitude heavy load lifting, the high - altitude heavy load lifting release beam is your ideal choice. We encourage you to further understand our product. Contact our company today to learn more about how this innovative product can meet your specific needs and enhance your operational efficiency.