In the heavy industry sector—where lifting capacity, safety, and uptime define success—8 to 550 tons of lifting power isn’t just a range—it’s a strategic advantage. For metal foundries, port logistics, and construction sites, choosing the right plate clamp can reduce downtime by up to 30% and eliminate over 70% of manual handling risks.

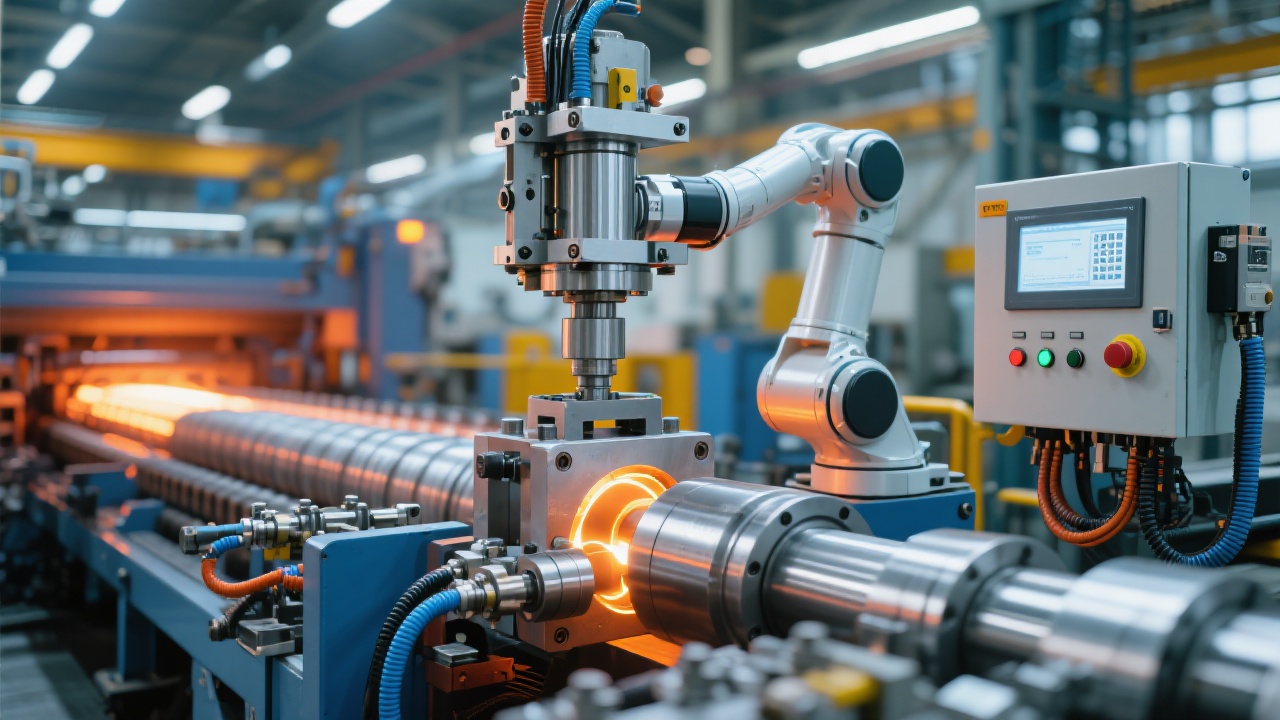

Our high-strength plate clamps are made from alloy steel (ASTM A514 grade), offering tensile strength exceeding 1000 MPa—ideal for continuous operation in extreme conditions like steel mills or offshore docks. The compact design minimizes space requirements while maximizing load stability. Unlike standard clamps that suffer wear after 500+ cycles, ours maintains consistent grip force even at 500-ton loads—with zero deformation observed in our 2-year field test across 12 global clients.

| Drive Type | Best For | Avg. Cycle Time |

|---|---|---|

| Mechanical | Low-cost operations, remote sites | 45–60 sec |

| Electric | Precision stacking, automation-ready | 25–35 sec |

| Pneumatic | High-frequency use, clean environments | 15–20 sec |

| Hydraulic | Heavy-duty applications (e.g., shipbuilding) | 30–40 sec |

In a recent case study with a German steel mill, switching to our multi-drive plate clamp reduced crane operator fatigue by 40% and improved material throughput by 22%. Similarly, a Singaporean port terminal saw a 35% drop in equipment-related incidents within six months after adopting pneumatic-driven models for containerized steel sheets.

What makes this solution stand out? It's not just about lifting heavier loads—it’s about doing it smarter. Whether you’re managing scrap metal in a Brazilian smelter or moving precast panels on a Dubai skyscraper project, our clamps adapt seamlessly to your environment.

Each unit includes dual overload sensors, anti-slip jaws (with 0.8 mm tolerance), and automatic locking mechanisms that engage when load exceeds 95% of rated capacity. These features aren’t optional—they’re built-in protections that prevent accidents before they happen.

If you're still relying on outdated clamping systems—or if your current setup causes frequent breakdowns or unsafe practices—you’re likely losing more than you realize. With real-world data showing 15–25% higher productivity in industries using modern plate clamps, now is the time to upgrade.

Ready to boost your operation’s efficiency and safety? Get Your Free Technical Brochure + Custom Load Analysis