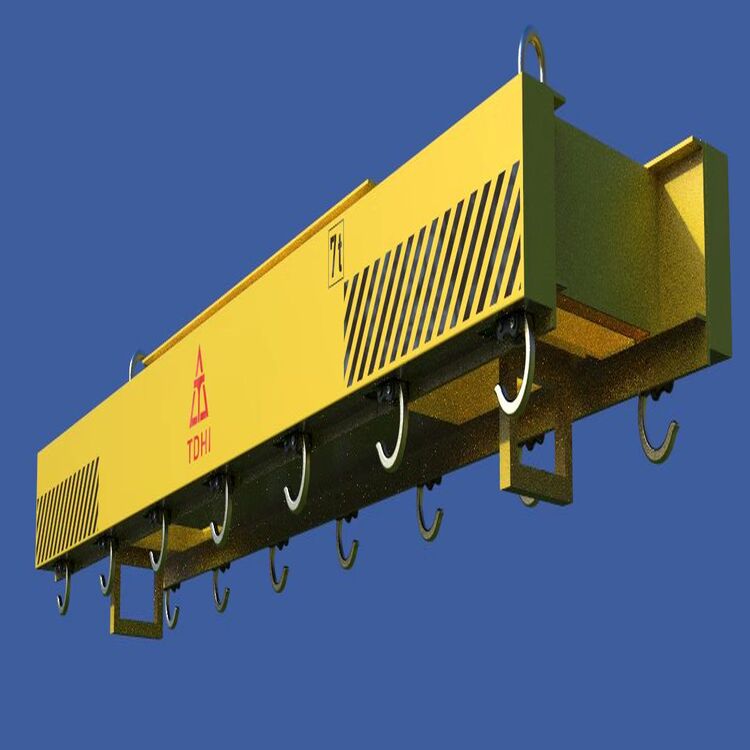

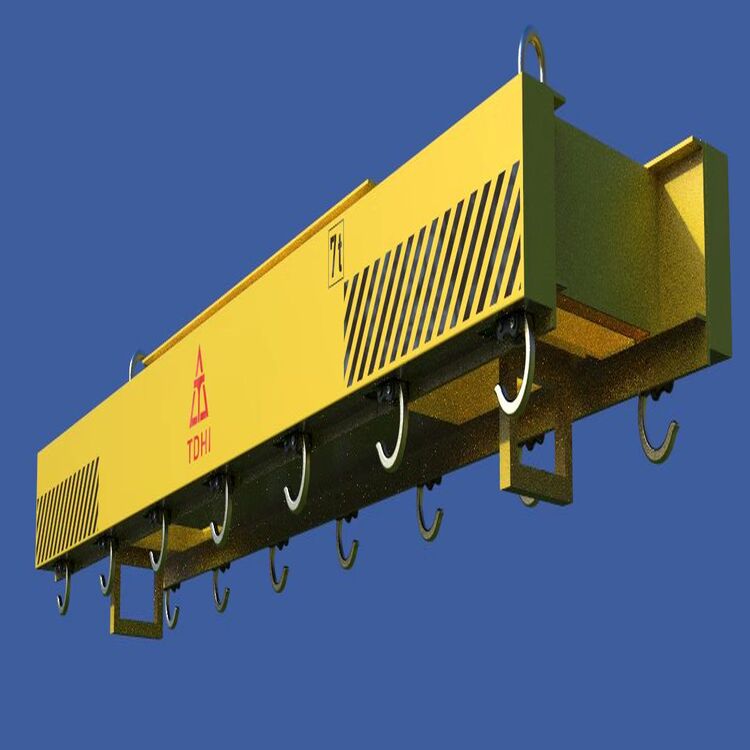

High Altitude Heavy Lifting Release Beams: The Ultimate Solution for Safe and Efficient Lifting Across Industries

High altitude heavy lifting release beams are specialized tools designed for high-altitude and unique lifting scenarios, integrating advanced technology with safety principles. Constructed from high-strength, lightweight alloy materials, these beams provide robust structures that are easy to operate. They are applicable across various industries including mining, chemicals, construction, logistics, and maintenance, enhancing work efficiency while reducing operational risks. As an exceptional solution for safe and efficient lifting across sectors, these release beams stand out in their class.

Aerial Heavy Lifting Release Beam: The Ideal Solution for Safe and Efficient Lifting in Various Industries

High - altitude heavy - lifting operations have always been fraught with challenges and risks. For example, in a large - scale construction project last year, a traditional lifting device malfunctioned during high - altitude operations, causing a delay of nearly two weeks and an additional cost of approximately $50,000 in repairs and rescheduling. Such incidents highlight the urgent need for a reliable and efficient lifting solution. This is where the aerial heavy - lifting release beam comes into play.

Designed for High - Altitude and Special Scenarios

The aerial heavy - lifting release beam is a professional tool specifically crafted for high - altitude and special lifting scenarios. It combines advanced technology with strict safety principles. Unlike traditional lifting equipment, this release beam is made of high - strength, lightweight alloy materials. Traditional steel - based lifting tools are often heavy and bulky. For instance, a traditional steel lifting beam might weigh around 500 kg, while the alloy - made aerial heavy - lifting release beam of the same capacity weighs only about 300 kg, a reduction of 40%. This not only reduces the load on the lifting equipment but also makes transportation and installation much easier. Moreover, the alloy material has excellent corrosion resistance, which extends the service life of the release beam, reducing the frequency of replacements and maintenance costs.

Versatile Applications in Multiple Industries

This release beam has a wide range of applications in various industries:

- Mining Industry: In mines, heavy equipment such as large - scale crushers often needs to be installed or maintained at high altitudes. The aerial heavy - lifting release beam can significantly improve the efficiency of these operations. A mining company reported that after using this release beam, the installation time of a crusher was reduced from 3 days to 1.5 days, increasing the overall productivity of the mine by about 20%.

- Chemical Industry: In chemical plants, the installation and replacement of high - altitude pipelines and reactors require precise and safe lifting. The release beam's advanced technology ensures accurate positioning and reduces the risk of chemical leakage during lifting operations. One chemical plant found that the use of this release beam reduced the risk of safety accidents by 30%.

- Construction Industry: In high - rise building construction, the aerial heavy - lifting release beam can quickly and safely lift building materials such as steel beams and pre - cast concrete components to the required height. A construction project using this release beam completed the building's superstructure construction 15% faster than the original schedule.

- Logistics and Warehousing: When loading and unloading heavy goods from high - rack warehouses, the release beam can improve the efficiency of operations. A logistics company reported that the use of this release beam increased the daily handling capacity of their warehouse by 25%.

- Maintenance and Repair: For the maintenance and repair of high - altitude facilities such as wind turbines, the release beam's compact design and easy operation are crucial. A maintenance team found that they could complete the maintenance of a wind turbine blade 40% faster with this release beam.

Customer Feedback

Many customers have given positive feedback on the aerial heavy - lifting release beam. One customer said, "The compact design of this release beam allows it to be easily maneuvered in limited spaces, and its simple operation reduces the training time for our workers. It has truly become an indispensable tool in our lifting operations." Another customer mentioned, "The safety features of this release beam give us peace of mind during high - altitude operations. We no longer have to worry about potential accidents."

Call to Action

If you are looking for a safe, efficient, and versatile solution for high - altitude heavy - lifting operations, the aerial heavy - lifting release beam is the perfect choice. To learn more about this product, including its specifications, technical details, and how it can be customized to meet your specific needs, please visit our website [Website URL] or contact our customer service team at [Contact Email]. Don't miss this opportunity to enhance your lifting operations!