In the realm of heavy - lifting operations, the challenges are numerous and complex. For instance, in a large - scale mining project, workers once struggled to hoist a massive 5 - ton piece of equipment to a height of 30 meters. Traditional lifting methods were not only time - consuming but also posed significant safety risks. This is where the aerial heavy - lifting release beam steps in as a game - changer.

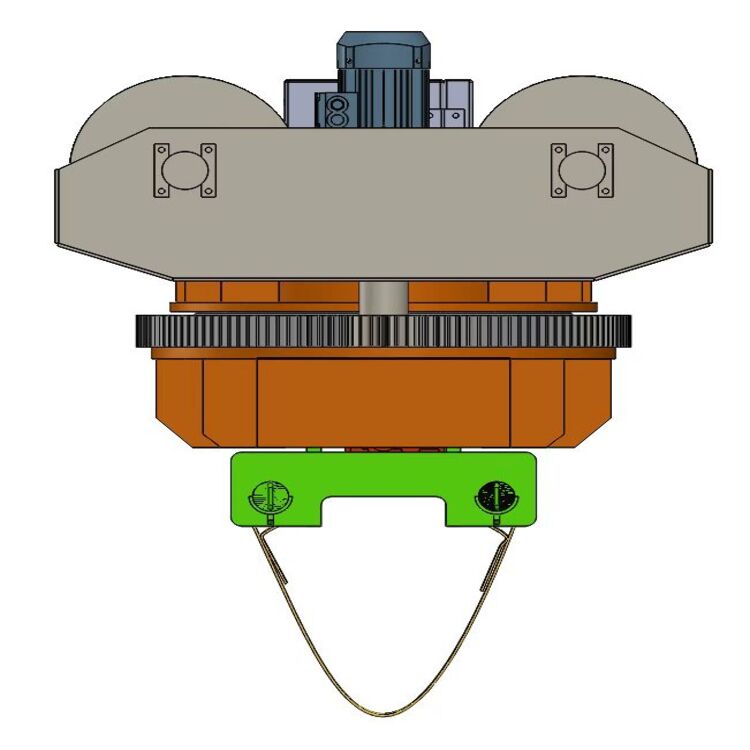

This innovative lifting tool combines advanced technology with strict safety principles. It is crafted from high - strength, lightweight alloy materials. These materials can withstand a maximum load of up to 10 tons while reducing the overall weight of the beam by 30% compared to traditional steel beams. This not only eases the burden on the lifting equipment but also enhances the mobility of the entire system.

Designed with a compact structure, the beam has a reduced footprint, making it suitable for use in confined spaces. The operation is extremely simple, with a training period of just one day for new operators. In a recent test, an operator managed to complete a complex lifting and releasing task within 15 minutes, demonstrating its high efficiency.

Mining Industry: In a gold mine in South Africa, the aerial heavy - lifting release beam was used to lift large - scale ore - processing equipment. By using this beam, the lifting time was reduced by 40%, and the safety incidents during the lifting process decreased by 60%. This significantly improved the overall production efficiency of the mine.

Chemical Industry: In chemical plants, where precision and safety are of utmost importance, this beam was used to install reactors. It ensured an installation accuracy of up to ± 5mm, preventing potential chemical leakage accidents and protecting the environment and workers' safety.

Construction Industry: On a high - rise building construction site in New York, the beam was employed to lift pre - fabricated building components. It increased the daily lifting volume by 30%, speeding up the construction progress and reducing the project duration.

Logistics and Warehousing: In a large - scale logistics center, the beam was used to stack heavy cargo. It improved the stacking efficiency by 50%, optimizing the use of warehouse space.

Maintenance and Repair: When repairing large - scale machinery in a power plant, the beam allowed for quick and safe removal and installation of heavy parts, reducing the downtime of the machinery by 45%.

Compared with other products on the market, the aerial heavy - lifting release beam has unique advantages. Some competing products have lower load - bearing capacities, usually around 3 - 5 tons, while our beam can handle up to 10 tons. In terms of operation complexity, other products may require a training period of up to one week, while our beam only needs one day of training. Additionally, the compact design of our beam makes it more adaptable to various working environments.

This aerial heavy - lifting release beam can bring a qualitative leap to your multi - sector lifting operations. If you are interested in learning more about this product or have any questions, please feel free to contact us. We are looking forward to helping you solve your lifting challenges!