In the highly competitive steel production industry, finding tools that can enhance efficiency and reduce costs is crucial. The high-efficiency power-type steel plate clamp emerges as a game-changer, specifically designed to meet the demanding requirements of the steel manufacturing process.

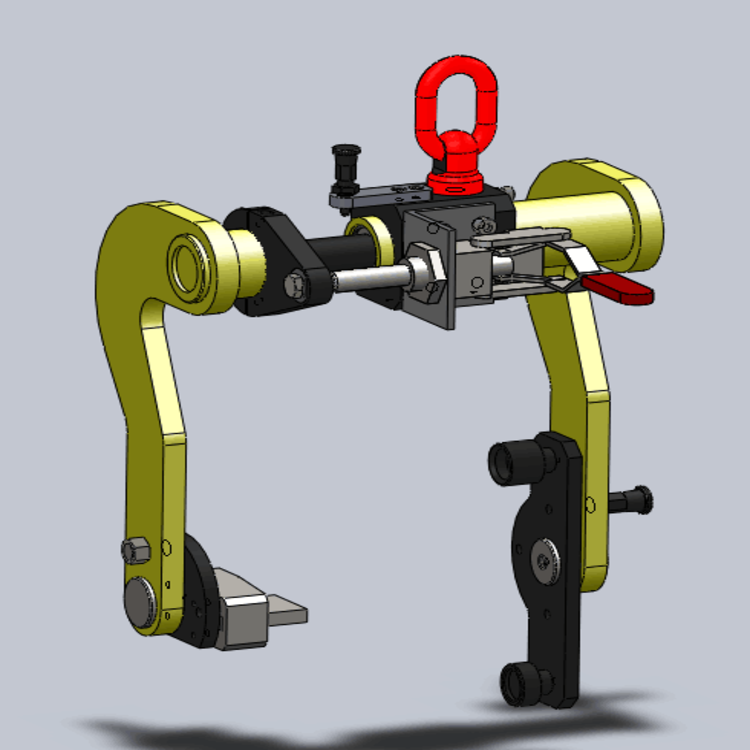

The high-efficiency power-type steel plate clamp is engineered for the continuous casting and transportation of high-temperature steel plates. Its hydraulic drive mechanism enables precise movement and adjustable clamping force. This is a significant advantage as it allows operators to handle steel plates of different sizes and weights with ease. The clamp is made of high-strength alloy steel, which is not only durable but also highly resistant to wear and tear, ensuring a long service life even in harsh industrial environments.

One of the key advantages of this clamp is its ability to achieve precise movement. This precision reduces the risk of errors during the handling process, leading to fewer accidents and improved safety. The adjustable clamping force feature allows the clamp to securely hold the steel plates without causing damage. Additionally, some models come with an automatic switch function, which further simplifies the operation and saves time.

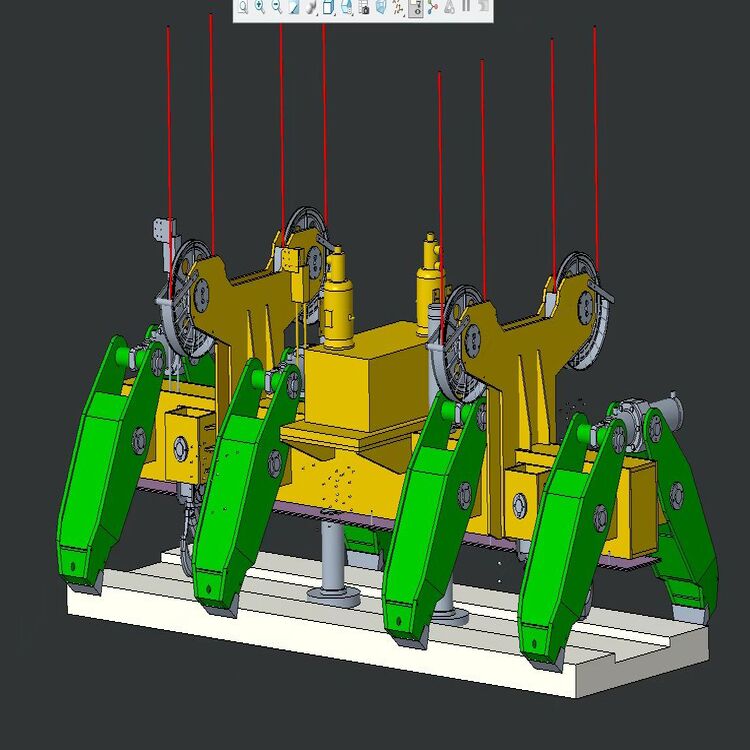

The high-efficiency power-type steel plate clamp is suitable for a variety of applications, including steel mills, hot-rolling plants, and continuous casting workshops. In steel mills, it can significantly increase the speed of steel plate handling, reducing the time required for each operation. In hot-rolling plants, the clamp's ability to withstand high temperatures ensures smooth and efficient production. In continuous casting workshops, it helps to maintain a continuous flow of steel plates, improving overall productivity.

Data shows that the use of this clamp can increase production efficiency by up to 30%. This increase in efficiency directly translates into cost savings. For example, a steel plant that previously took 10 hours to complete a certain volume of steel plate handling can now achieve the same output in just 7 hours, reducing labor costs and energy consumption.

Many steel enterprises have already benefited from using the high-efficiency power-type steel plate clamp. One large-scale steel mill reported that after adopting this clamp, their production line uptime increased from 80% to 95%. This not only improved their overall production capacity but also enhanced their competitiveness in the market.

Compared with traditional clamps, the high-efficiency power-type steel plate clamp offers several significant improvements. Traditional clamps often lack the precision and adjustable clamping force, which can lead to damage to the steel plates and a higher risk of accidents. Moreover, traditional clamps are usually more labor-intensive and time-consuming to operate. In contrast, the high-efficiency power-type steel plate clamp streamlines the process, making it more efficient and safer.

Industry experts believe that the high-efficiency power-type steel plate clamp represents the future of steel plate handling technology. The hydraulic drive mechanism and high-strength materials used in this clamp are the result of continuous innovation in the industry. As the demand for higher efficiency and lower costs in steel production continues to grow, the popularity of this clamp is expected to increase.

Do you have any questions about the high-efficiency power-type steel plate clamp? Or do you want to share your experiences with similar products? Leave your comments below, and our team will be happy to answer your questions.

Don't miss out on the opportunity to revolutionize your steel production process. Contact us today to learn more about how the high-efficiency power-type steel plate clamp can help your business enhance productivity, reduce costs, and gain a competitive edge in the market!