In continuous casting workshops, the demand for efficient material handling is critical. The traditional methods of moving hot steel plates often face significant delays and risks, which can impede the overall production process. This article will explore how high - efficiency power - type steel plate clamps can address these issues and optimize the steel production process.

Continuous casting workshops are at the heart of steel production. The ability to quickly and safely move hot steel plates from the casting area to the next stage is crucial for maintaining a smooth production flow. Traditional handling methods, such as manual or semi - automated systems, are often slow and fraught with risks. These delays can lead to longer production cycles, increased energy consumption, and a higher likelihood of accidents.

Traditional handling methods rely on workers to manually operate lifting equipment or use simple mechanical clamps. This approach has several drawbacks. Firstly, it takes time for workers to position the clamps accurately, which causes delays between the casting and the transportation of hot steel plates. Secondly, manual operation is prone to human error, increasing the risk of dropping the hot steel plates, which can lead to serious accidents and damage to equipment.

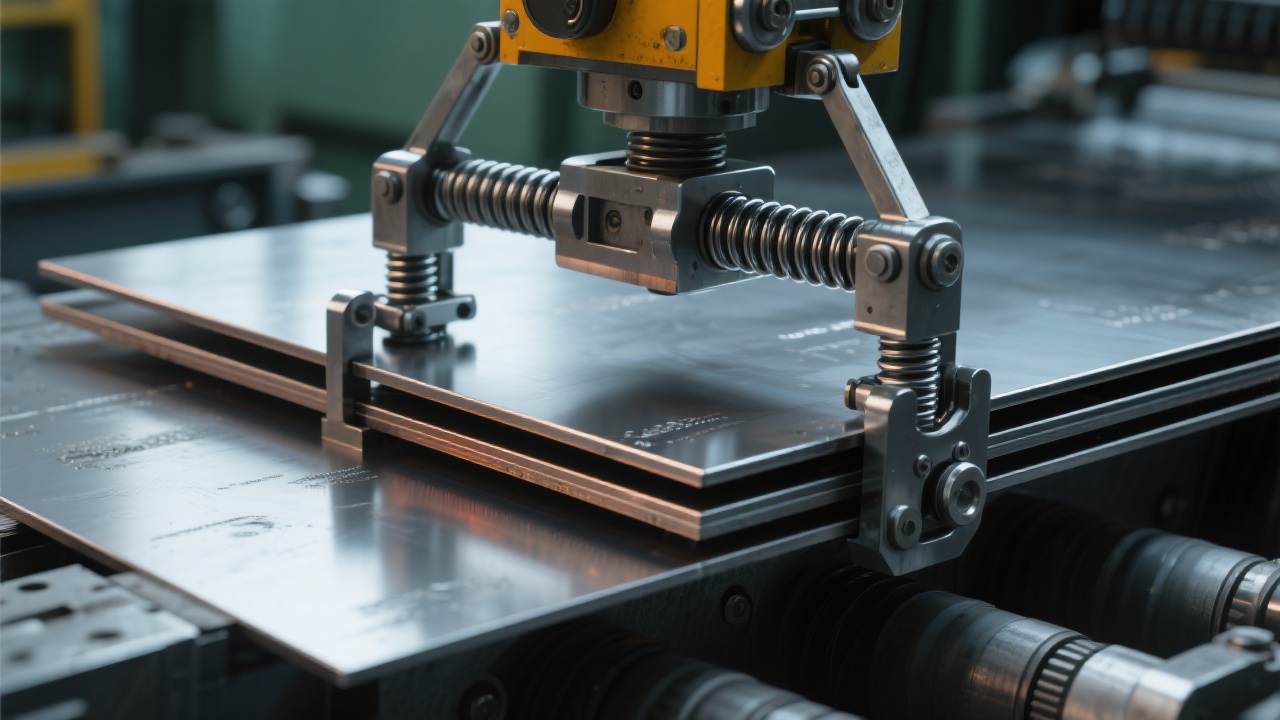

High - efficiency power - type steel plate clamps are equipped with advanced technologies that offer significant improvements over traditional methods. The key features include hydraulic drive, adjustable clamping force, and an automatic switch function.

The hydraulic drive system provides precise control over the clamping and lifting process. It can generate a large amount of force quickly, allowing the clamp to grip the hot steel plate firmly and securely. This ensures that the plate can be lifted and transported without any slippage.

The adjustable clamping force feature allows the operator to set the appropriate force according to the size and weight of the steel plate. This flexibility ensures that the clamp can handle different types of steel plates without causing damage to the plates or the equipment.

The automatic switch function enables the clamp to open and close automatically, reducing the need for manual intervention. This not only speeds up the handling process but also improves safety by minimizing the operator's exposure to hot steel plates.

One of the most significant advantages of high - efficiency power - type steel plate clamps is their ability to transport hot steel plates immediately after casting. This eliminates the waiting time associated with traditional methods, significantly shortening the production cycle.

A real - world example from a steel mill shows the remarkable benefits of these clamps. After implementing high - efficiency power - type steel plate clamps, the production cycle was shortened by 15%. This reduction in production time means that the steel mill can produce more steel products in the same amount of time, increasing its overall productivity.

In addition, the accident rate decreased by 40%. The precise control and automatic functions of the clamps reduce the risk of human error, making the handling process much safer. As one manager from the steel mill put it in a quote box: "These clamps have transformed our production process. We've seen a significant improvement in both efficiency and safety."

High - efficiency power - type steel plate clamps are designed to be adaptable to various scenarios. They can be used in different types of continuous casting workshops, regardless of the size or production capacity of the factory. Moreover, these clamps are built to last, with high - quality materials and robust construction. Their long - term durability means that factories can rely on them for continuous operation, reducing the need for frequent replacements and maintenance.

High - efficiency power - type steel plate clamps are a key piece of equipment for lean production in the steel industry. Their advanced technological features, practical application effects, and long - term value make them an ideal choice for steel enterprises looking to optimize their casting processes. By using these clamps, steel companies can shorten production cycles, improve safety, and enhance their competitiveness in the market. Let every minute create value. Say goodbye to waiting and start a new rhythm of high - efficiency production. Discover how our high - efficiency power - type steel plate clamps can transform your steel production process today!