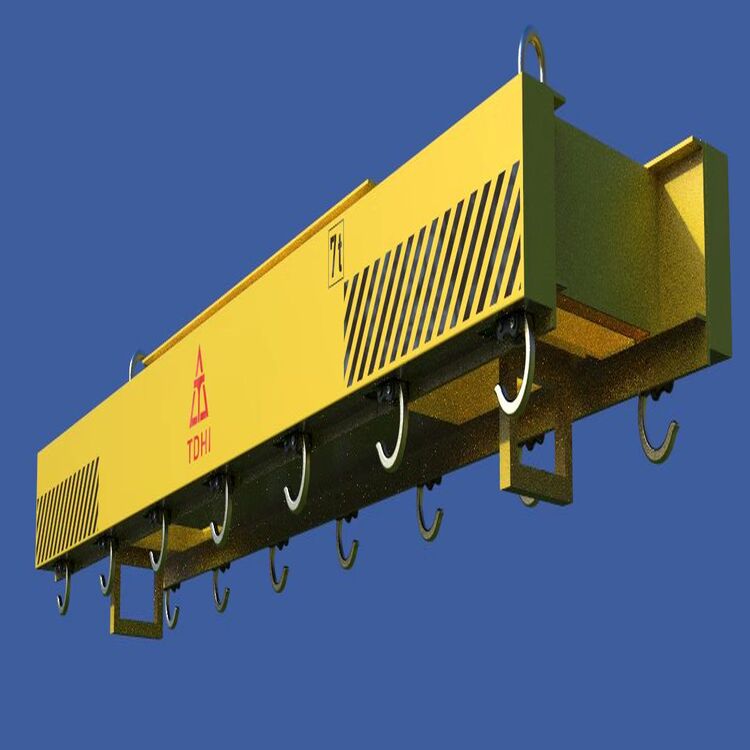

The global mining sector continually seeks advanced solutions that enhance operational safety and improve productivity amid increasingly complex extraction environments. Multifunctional high-altitude heavy load release beams, engineered from high-strength lightweight alloys, are emerging as pivotal tools that address these industry demands. These cutting-edge devices offer a combination of precision lifting, secure load release from elevated positions, and durable structural integrity, making them indispensable in modern mining operations worldwide.

A critical advancement behind these multifunctional lifting tools lies in their material composition. The adoption of high-strength aluminum and titanium alloys results in significantly reduced device weight—up to 35% lighter compared to conventional steel lifting beams—without compromising load-bearing capacity. This innovation not only facilitates easier transportation and installation in challenging high-altitude mining sites but also reduces operator fatigue and mechanical strain during operations.

The multifunctional tool’s capability for precise high-altitude load placement and controlled release significantly mitigates risks associated with traditional dangling or manual lifting methods. According to recent industry safety reports, incidents related to lifting accidents account for approximately 12% of mining site injuries globally. Implementation of these tools has demonstrated a potential reduction of up to 40% in load-handling accidents, underlining a substantial safety impact.

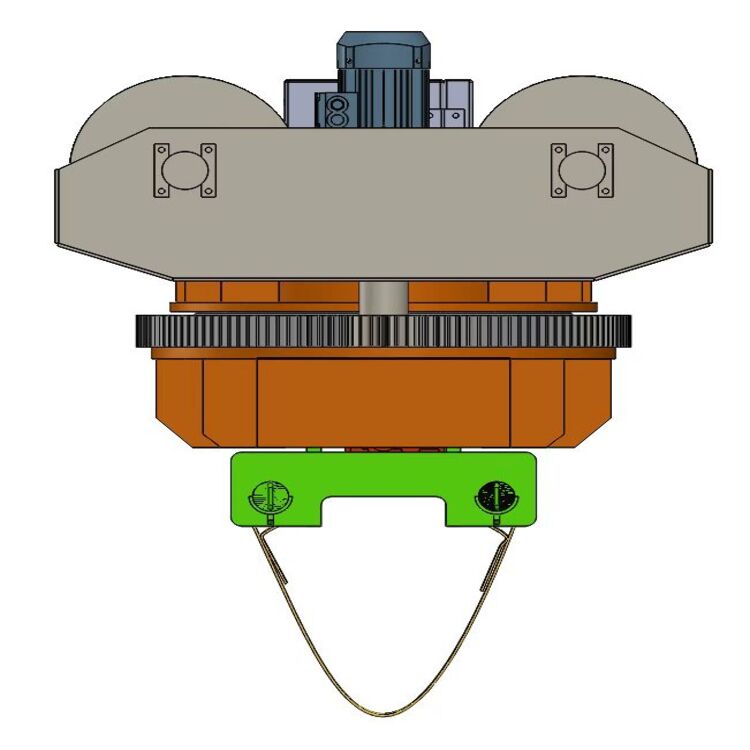

Furthermore, the integrated high-altitude release mechanism allows operators to control load disengagement remotely or via automated systems, minimizing human exposure to hazardous zones. This technology thereby aligns seamlessly with industry standards such as ISO 14001 and OHSAS 18001, promoting safer work environments.

Time efficiency is paramount in mining projects, where equipment downtime translates to significant financial loss. Case studies from leading mining operations in Australia and Canada reveal that utilizing multifunctional lifting beams can reduce equipment setup and load transition time by 25-30%, effectively increasing overall productivity.

Additionally, the durability of the high-grade materials used lowers maintenance frequency and costs by approximately 20% annually. This translates to reduced unscheduled stoppages, ensuring continuous operation—a critical factor in meeting production targets and contractual obligations.

The global mining market, valued at over $1.7 trillion as of recent estimates, is rapidly embracing such multifunctional equipment. Procurement specialists emphasize that multifunctionality and enhanced safety features constitute primary criteria in supplier evaluation, elevating these tools to preferred status.

Integration of multifunctional high-altitude load release beams optimizes capital expenditure by replacing multiple single-purpose tools, enabling operational versatility in diverse mining scenarios—from underground shafts to open-pit sites across continents. Additionally, compliance with international safety and environmental regulations bolsters the tools’ appeal among global stakeholders.

Multifunctional high-altitude heavy load release beams present a compelling value proposition for mining operations worldwide. By enhancing safety protocols, elevating precision in load handling, and diminishing operational downtime, these tools substantially improve workflow efficiency and asset longevity.

For procurement decision-makers searching for solutions that combine durable construction, multifunctionality, and compliance with stringent industry standards, this innovative lifting technology represents an optimal investment with tangible results.