In the fast - paced automotive industry, production efficiency and safety are of utmost importance. Traditional lifting tools often present a series of problems that hinder the smooth progress of production. For example, a well - known automotive manufacturing plant once faced significant delays due to the low - efficiency and high - maintenance traditional lifting tools. The heavy - duty materials of these traditional tools not only increased the labor intensity of workers but also required frequent repairs, resulting in a 20% reduction in production efficiency.

The newly designed automobile production line lifting tool is a game - changer. It uses high - strength lightweight materials, which are 30% lighter than traditional materials while maintaining the same level of strength. This reduction in weight significantly reduces the energy consumption during operation and the physical burden on workers.

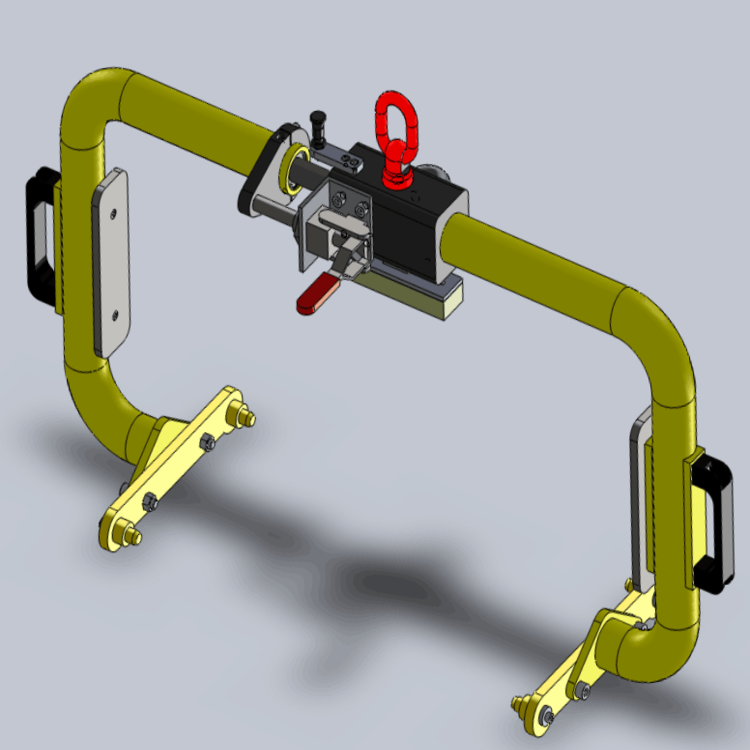

One of the most remarkable features is its unique clamping mechanism, similar to a universal clamp. It can firmly hold various shapes and sizes of automotive parts, eliminating the need for multiple types of lifting tools. Moreover, the adjustable function allows it to adapt to different working heights and angles, providing greater flexibility in the production process.

In the automotive manufacturing scenario, this lifting tool has been proven to increase production efficiency by 35%. Workers can complete tasks more quickly and accurately, reducing the time spent on handling parts. In the automotive repair workshop, it reduces the labor intensity of mechanics by 40%. They no longer have to struggle with heavy and cumbersome traditional tools.

Here are some real - user evaluations: "This lifting tool has completely changed our production process. We have seen a significant improvement in efficiency and a decrease in accidents," said a production manager from a large - scale automotive factory. "As a mechanic, I used to dread lifting heavy parts. Now, with this tool, my work has become much easier," shared a technician from an auto - repair shop.

This innovative lifting tool plays a crucial role in promoting the intelligent and efficient development of the automotive industry. It is compatible with automated production lines, enabling seamless integration with other intelligent manufacturing equipment. As the industry moves towards greater automation, this tool will become an indispensable part of the production process.

In the future, with the continuous improvement of automotive technology and the increasing demand for high - quality production, the application prospects of this lifting tool are very broad. It can be used in new - energy vehicle production, high - end automotive customization, and other emerging fields.

The core advantages of this automobile production line lifting tool include high - strength lightweight materials, a unique clamping mechanism, and adjustable functions. These features not only improve production efficiency, ensure safety, and reduce labor intensity but also contribute to the sustainable development of the automotive industry.

If you are looking for a reliable solution to improve your automotive production or repair process, we encourage you to learn more about this innovative lifting tool. Click here to get detailed product information and start your journey towards a more efficient and safer automotive production.