In the fast - paced automotive industry, the efficiency and safety of production lines are of utmost importance. Traditional slings in the automotive industry have long been a headache for many manufacturers. Let's start with a real - life story. A few years ago, a medium - sized automotive factory was struggling with its production efficiency. The old - fashioned slings they used were heavy and cumbersome. One day, during a crucial assembly process, a sling malfunctioned, causing a delay of nearly 3 hours and a loss of approximately $50,000 in that single day. This incident clearly shows the severity of the problems associated with traditional slings.

The automotive production line multi - functional lifting tool is a game - changer. First of all, it is made of high - strength lightweight materials. Compared with traditional steel slings, which can weigh up to 50% more, these new materials reduce the weight significantly while maintaining high strength. For example, the new material can withstand a pulling force of up to 10 tons, just like traditional materials, but it is much easier to handle.

Another outstanding feature is its unique clamping mechanism. Unlike traditional slings that rely on simple hooks or loops, this tool has a self - adjusting clamping system. It can automatically adapt to different shapes and sizes of automotive parts, ensuring a secure grip. Moreover, it has adjustable functions. The height and angle of the lifting can be easily adjusted according to the specific requirements of the production process.

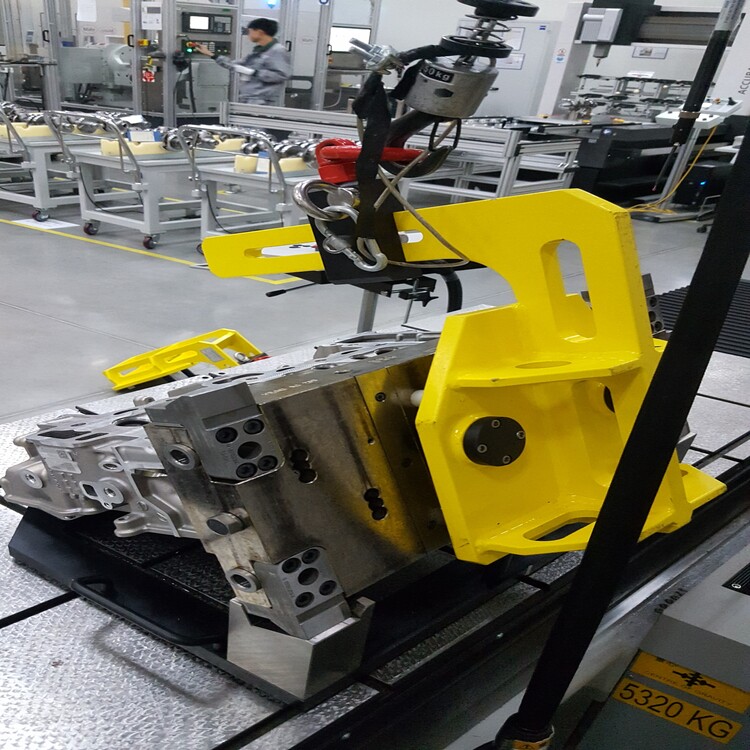

Take a look at these amazing pictures of the product:

In the scenarios of automotive manufacturing and maintenance, this tool brings huge value. In terms of efficiency improvement, a large automotive manufacturing plant reported that after using this new lifting tool, the assembly time for each vehicle was reduced by 20%. In the maintenance process, mechanics can complete tasks 30% faster because they no longer have to struggle with heavy and inflexible slings.

Safety is also greatly enhanced. The secure clamping mechanism reduces the risk of parts falling during lifting, which was a major safety concern with traditional slings. A survey showed that the number of accidents related to lifting operations decreased by 40% after the adoption of this new tool.

Let's take a look at some real - user evaluations. A mechanic named Tom said, "This lifting tool has completely changed my work. It's so much easier to use, and I don't have to worry about my back hurting after a long - day job."

This innovative lifting tool is playing a significant role in promoting the intelligent and efficient development of the automotive industry. It can be integrated with automated production systems, allowing for more precise and efficient operations. In the future, as the automotive industry continues to evolve towards greater automation and intelligence, the application prospects of this tool are extremely broad. It can be used in more complex production environments and for handling a wider variety of automotive parts.

To sum up, the automotive production line multi - functional lifting tool has many core advantages, including high - strength lightweight materials, unique clamping mechanisms, and adjustable functions. It significantly improves work efficiency, enhances safety, and reduces labor intensity. This product is not only a revolutionary tool for the current automotive industry but also an important factor in promoting the sustainable development of the automotive industry.

If you are interested in learning more about this amazing product, please feel free to contact us at [Contact Email] or call us at [Contact Phone]. We are looking forward to your inquiry!