In the years of working in the steel industry, it's been found that the most common pitfall for purchasers during high - temperature steel plate transportation is the lack of a reliable and safe handling solution. Traditional methods often face issues such as low efficiency, high accident risks, and potential harm to workers' health. The power - type steel plate clamp emerges as a revolutionary solution to these problems.

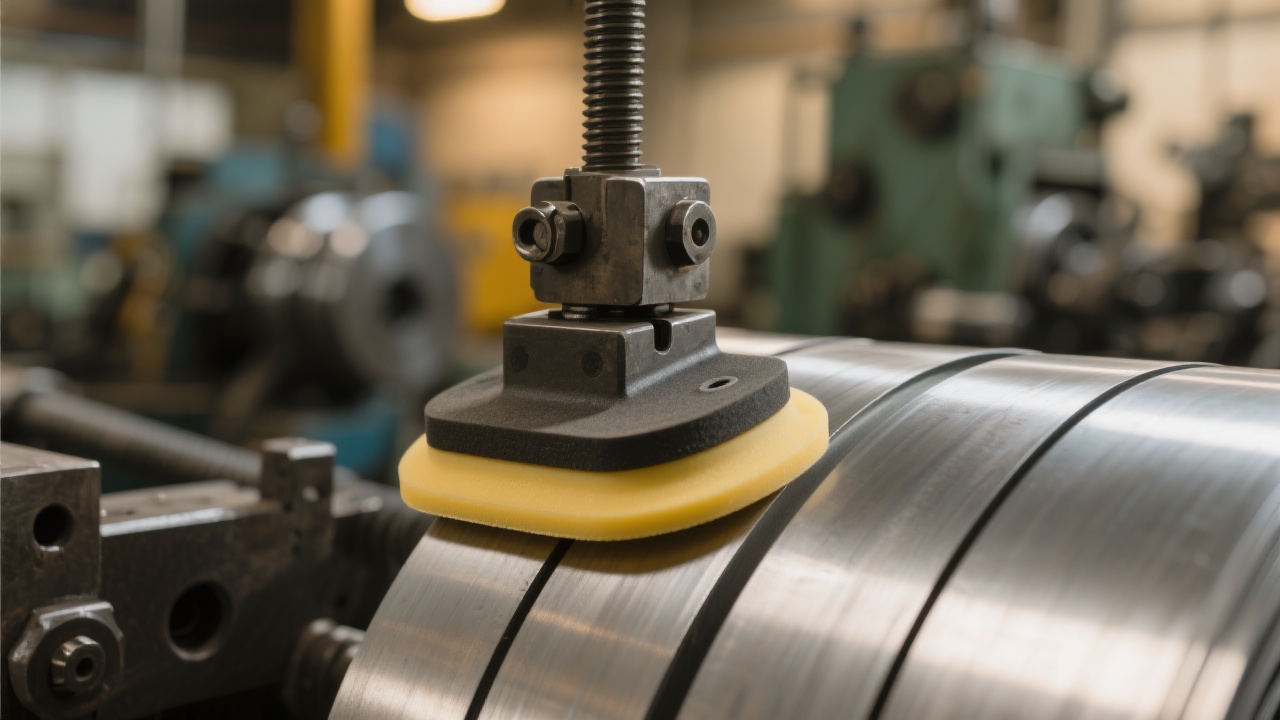

The power - type steel plate clamp is a hydraulic - driven lifting tool specially designed for the steel industry. Its technical features and design advantages make it highly valuable in continuous casting and high - temperature steel plate handling. The use of high - strength alloy steel in its construction provides excellent durability. This material can withstand the high - temperature environment in steel plants, with a heat resistance of up to 600°C, ensuring a long service life even under extreme conditions.

One of the core selling points is its hydraulic drive mechanism. The hydraulic system allows for precise control of the clamping force. For example, it can adjust the clamping force according to the thickness and weight of the steel plate, with an accuracy error of less than ±5%. This precision not only improves the safety of lifting but also enhances the efficiency of the handling process. Another key feature is the automatic switch function. Once the clamp is in place and detects the proper position and pressure, it automatically locks, reducing the need for manual operation and minimizing human - error risks.

In steel plants, where high - temperature steel plates are produced continuously, the power - type steel plate clamp significantly improves the production efficiency. In a typical steel plant, the use of this clamp has increased the daily handling volume of high - temperature steel plates by 30% compared to traditional methods. In hot - rolling mills, the clamp's ability to handle high - temperature plates with precision helps maintain the quality of the steel products. The automatic switch function ensures that the steel plates are lifted and transported without damage, reducing the scrap rate by about 15%.

In logistics centers, the clamp enables quick and safe loading and unloading of steel plates. It can handle multiple steel plates at once, depending on the model, which speeds up the logistics process. For instance, in a large - scale logistics center, the average loading and unloading time for a batch of steel plates has been reduced from 2 hours to 1 hour with the use of this clamp.

Transporting steel plates in high - temperature and harsh environments presents several challenges, such as thermal expansion of the clamp components and the risk of sudden loss of clamping force. The power - type steel plate clamp addresses these issues effectively. The high - strength alloy steel material has a low thermal expansion coefficient, which ensures the stability of the clamp's structure even at high temperatures. The hydraulic system is also designed with redundant safety features. For example, it has a backup pressure system that can maintain the clamping force in case of a primary system failure, reducing the safety risk by up to 80%.

Many users have provided positive feedback on the power - type steel plate clamp. A steel plant in Germany reported that after using this clamp, the number of safety accidents related to steel plate handling has decreased from 5 cases per month to almost zero. Another hot - rolling mill in Japan found that the overall production efficiency has increased by 25% due to the improved handling speed and reduced downtime caused by equipment failures.

These case studies clearly demonstrate that the power - type steel plate clamp can bring significant business improvements and safety guarantees. It not only reduces the accident risk but also optimizes the production process, leading to higher productivity and cost savings.

To better understand the power - type steel plate clamp, multimedia content such as structural schematics and operation videos can be very helpful. These visual materials can enhance brand trust and user understanding. If you are interested in learning more about how this product can transform your high - temperature steel plate transportation, click here to explore further and communicate with our experts. Do you have similar problems in your industry? Share your specific scenarios with us, and we'll send you 3 solution cases from the same industry.