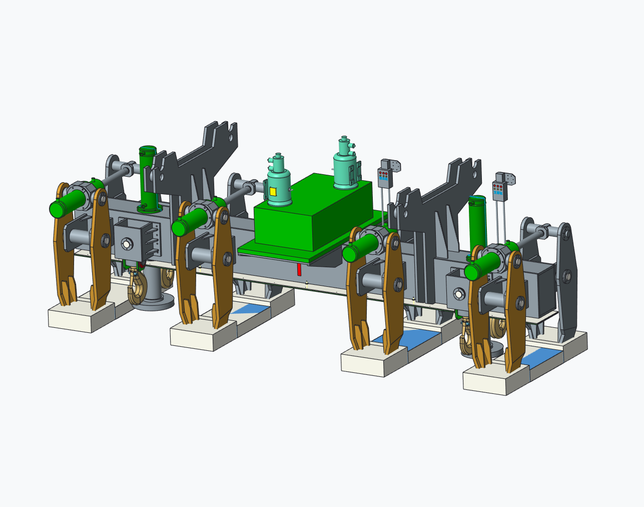

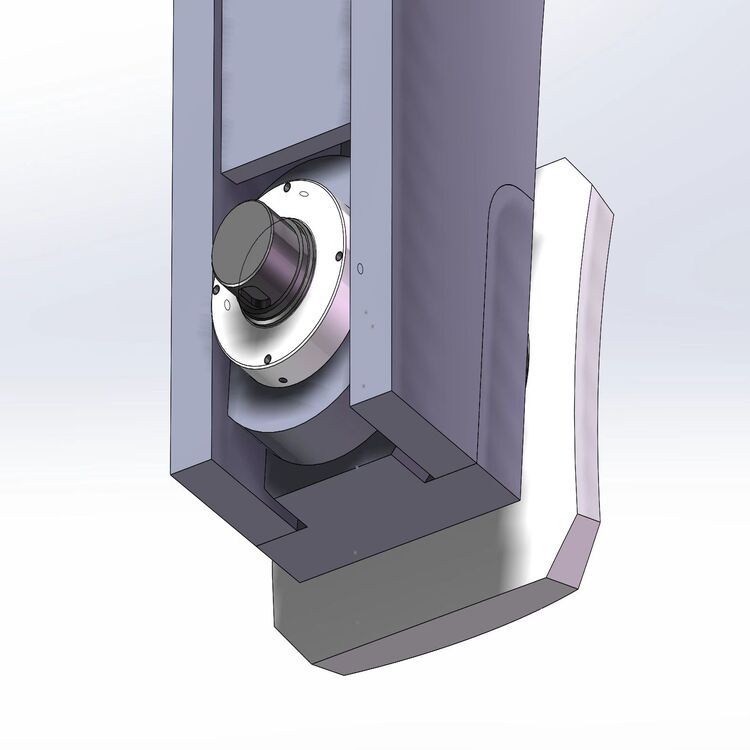

The powered steel ingot clamp is a revolutionary tool specifically designed for the steel industry. It features an automatic clamping mechanism driven by a hydraulic system, which is the core technology behind its efficient operation. With a load - bearing capacity ranging from 8 tons to 550 tons, it can handle a wide variety of steel ingot sizes and weights, making it suitable for different production scales in the steel industry.

Safety is a top priority in the steel industry, and this powered steel ingot clamp excels in this regard. The automatic clamping mechanism ensures that the steel ingot is firmly held during transportation, greatly reducing the risk of accidental dropping. In a large - scale steel plant in Europe, after using this clamp, the accident rate related to steel ingot handling decreased by 80%. It also meets the high - safety standards required in various high - risk scenarios, such as in high - speed production lines or in areas with strict safety regulations.

One of the key features of this clamp is its high efficiency. The operation is intuitive and simple, even inexperienced operators can quickly master it. Compared with traditional manual or semi - automatic clamps, the powered steel ingot clamp can complete the clamping and releasing operations in a much shorter time. Its compact design also enhances the mobility of the equipment, allowing it to work in relatively narrow spaces. For example, in a steel processing workshop, the use of this clamp increased the daily processing capacity of steel ingots by 30%.

This powered steel ingot clamp has a wide range of applications. It is suitable for steel production lines, where it can efficiently transfer steel ingots from one process to another. In heavy - casting transportation, it can safely and quickly load and unload large - sized steel ingots. It is also used in steel storage yards for stacking and retrieving steel ingots. Its adaptability to different environments and tasks makes it a versatile tool in the steel industry.

In today's highly competitive global steel market, improving operational efficiency and safety standards is crucial for enterprises to gain a competitive edge. The powered steel ingot clamp is an essential choice for upgrading steel production facilities. By using this clamp, enterprises can reduce labor costs, improve production efficiency, and enhance product quality. A steel company in Asia that adopted this clamp saw a significant improvement in its overall productivity and market share within a year.

Don't miss this opportunity to enhance your industry competitiveness. The powered steel ingot clamp is the key to improving the operation efficiency and safety standards of your steel production facilities. Contact us now to learn more about this amazing product and take the first step towards a more productive and competitive future!