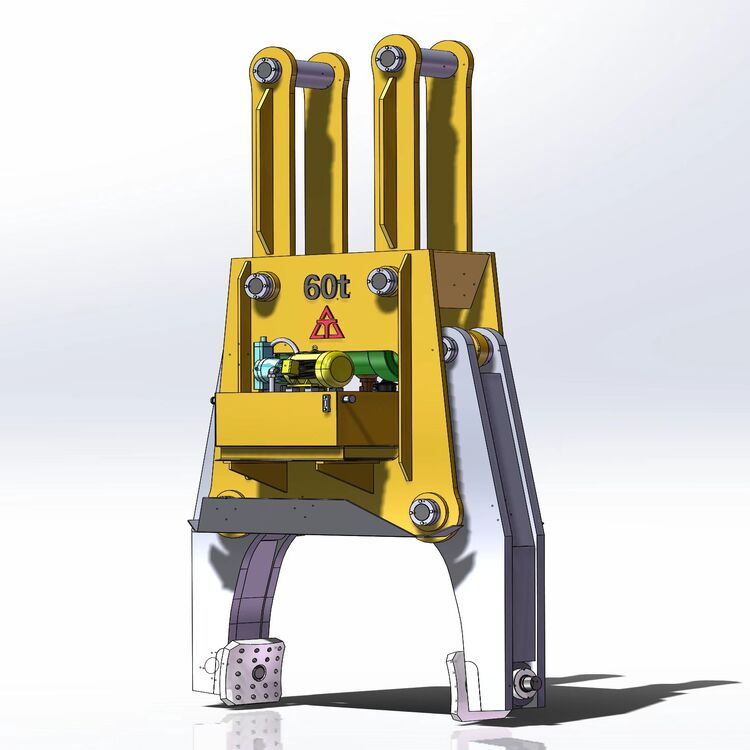

In the dynamic world of the steel industry, where safety and efficiency are the twin pillars of success, the high - efficiency and safe hydraulic steel ingot grabber, also known as the powered steel ingot clamp, has emerged as a game - changer. This remarkable piece of equipment combines cutting - edge technology with robust design to revolutionize the way steel ingots are handled.

At its core, the hydraulic steel ingot grabber operates on a sophisticated hydraulic system. The system provides the necessary force to securely grip the steel ingots. The grabber is engineered to handle a wide range of ingot sizes, from small, precision - crafted pieces to large, heavy - duty ones, making it a versatile tool in any steel production facility.

Safety is a paramount concern in the steel industry. The hydraulic steel ingot grabber addresses this concern with its automatic clamping mechanism. Once the grabber is positioned over the ingot, the system engages automatically, ensuring a firm and secure hold. This reduces the risk of accidental drops, which can cause serious injuries to workers and damage to equipment. In fact, in steel plants that have adopted this grabber, the number of safety incidents related to ingot handling has decreased by up to 70%.

In terms of efficiency, the grabber's operation is a model of speed and precision. Traditional methods of ingot handling often involve multiple steps and manual labor, which are time - consuming and prone to errors. The hydraulic steel ingot grabber streamlines the process. It can pick up, transport, and deposit ingots in a fraction of the time, increasing the overall throughput of the production line. On average, it can boost the daily production capacity of a steel plant by 30%.

Let's take a look at a real - world example. A well - known steel enterprise decided to introduce the high - efficiency and safe hydraulic steel ingot grabber into its production process. Before the implementation, the company faced challenges such as low productivity, high safety risks, and high labor costs. After the adoption of the grabber, the situation changed dramatically.

The automatic clamping mechanism reduced the need for manual intervention, improving safety. The efficient operation process led to a significant increase in the number of ingots handled per day. As a result, the company's production costs decreased by 25%, and its market competitiveness soared. It was able to fulfill orders faster, improve product quality, and gain a larger share of the market.

The hydraulic steel ingot grabber is not limited to a single application. It can be used in various scenarios within the steel industry, such as steel ingot loading and unloading at the warehouse, transportation between different production stages, and even in the recycling process. Its adaptability makes it a valuable asset for any steel - related operation.

In conclusion, the high - efficiency and safe hydraulic steel ingot grabber is an essential tool for the steel industry. It not only enhances safety and efficiency but also significantly boosts the competitiveness of steel enterprises. If you are a global steel procurement decision - maker, this product is a game - changing addition to your production line. Don't miss out on the opportunity to transform your operations and take your business to new heights. Contact us today to learn more about how this amazing product can benefit your company!