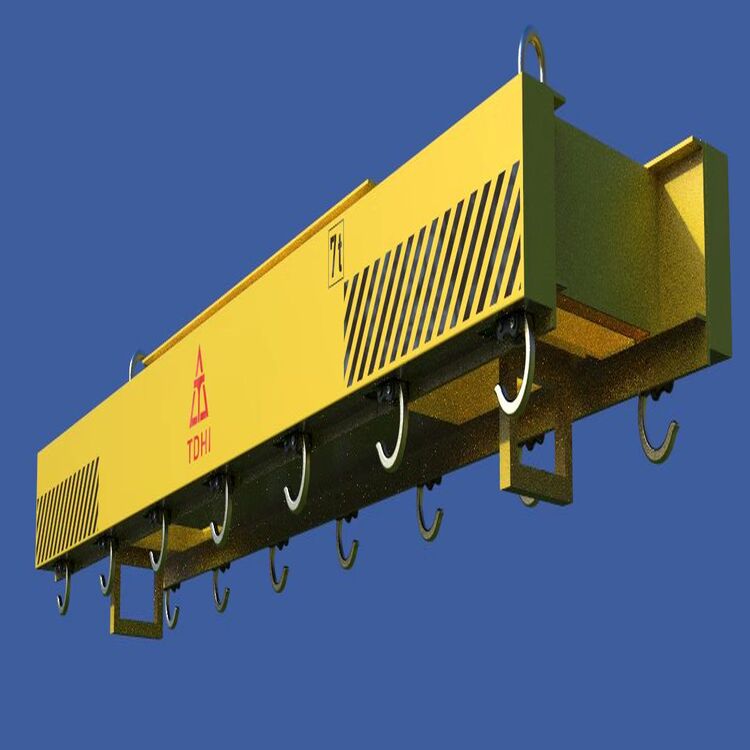

In the realm of heavy lifting operations, challenges abound. Consider a scenario in a large - scale construction project where a team needed to hoist heavy steel beams to a height of over 50 meters. Traditional lifting methods were not only time - consuming but also carried significant safety risks. This is where the high - altitude heavy lifting release beam comes into play, a revolutionary tool that is set to transform the landscape of lifting operations across various industries.

This innovative release beam is built upon advanced technology. For instance, it is equipped with a state - of - the - art control system that allows for precise and real - time adjustments during the lifting process. The accuracy of this control system can reach up to 0.1 degrees in angle adjustment, ensuring that the heavy objects are lifted and placed with extreme precision.

Safety is a top priority in its design. The release beam adheres to strict safety principles, using fail - safe mechanisms. In case of any power outage or system malfunction, the beam can lock the load securely, preventing any potential accidents. It is also made of high - strength and lightweight materials, such as carbon fiber - reinforced composites. These materials reduce the overall weight of the beam by up to 30% compared to traditional steel beams, while still maintaining a high load - bearing capacity of up to 50 tons.

**Mining Industry**: In a large gold mine, the high - altitude heavy lifting release beam was used to lift heavy mining equipment to underground work areas. It increased the lifting efficiency by 40%, reducing the downtime of the mining operations. The precise placement also minimized the risk of damage to the expensive equipment.

**Chemical Industry**: When installing large - scale chemical reaction vessels, the release beam's accurate control system ensured that the vessels were placed in the correct position within millimeters. This improved the overall safety of the chemical production process by reducing the chances of leaks and other hazards.

**Construction Industry**: As mentioned earlier, in high - rise building construction, the release beam can quickly and safely lift heavy building materials to great heights. It has been shown to shorten the construction period of a 30 - story building by up to 20%.

**Logistics and Warehousing**: In large - scale logistics centers, the release beam can efficiently stack heavy pallets of goods, increasing the storage density by 30% and improving the overall logistics efficiency.

**Maintenance and Repair**: When servicing large - scale machinery, such as wind turbines, the release beam can precisely lift and replace damaged parts, reducing the maintenance time from days to hours.

Compared with other lifting tools on the market, the high - altitude heavy lifting release beam stands out. Its advanced technology and lightweight materials give it a significant edge in terms of efficiency and safety. Many similar products lack the precise control system and high - strength lightweight materials, resulting in lower accuracy and higher risks during lifting operations.

In conclusion, the high - altitude heavy lifting release beam is a game - changer for lifting operations in multiple fields. It offers enhanced safety, precision, and efficiency, bringing a qualitative leap to the lifting work of various industries. If you are interested in learning more about this amazing product or would like to contact our company for further inquiries, please do not hesitate. Unlock the potential of your lifting operations with our high - altitude heavy lifting release beam!

Contact us now to explore how our high - altitude heavy lifting release beam can benefit your business!