High-efficiency powered steel plate clamps have emerged as a game-changer in the steel industry. Through their advanced hydraulic drive mechanism, automatic switch function, and other advantages, they play a crucial role in helping steel enterprises reduce costs and increase efficiency in various scenarios such as steel production facilities, hot rolling mills, and more. This article will unveil the details through real customer cases.

Many steel enterprises are constantly seeking ways to optimize their production processes and cut costs. One such enterprise, [Enterprise Name], was facing challenges in handling steel plates efficiently. The traditional methods were time - consuming, labor - intensive, and prone to errors, leading to increased production costs and lower efficiency.

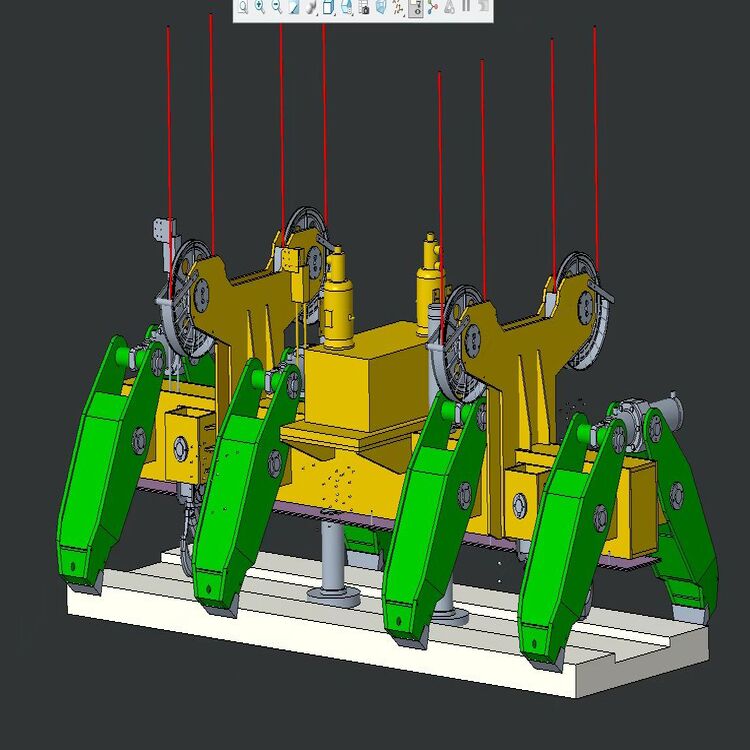

The high - efficiency powered steel plate clamps come with several remarkable features. First, the hydraulic drive mechanism provides strong and stable power. It can lift heavy steel plates with ease, reducing the time required for loading and unloading operations. Second, the clamps can achieve precise movement, which is essential for accurate placement of steel plates in the production line. Third, the adjustable clamping force allows the clamps to adapt to different types and sizes of steel plates, ensuring a secure grip. Finally, the automatic switch function simplifies the operation process, enabling workers to quickly start and stop the clamping action.

Steel Production Facilities: In steel production facilities, the clamps are used to transfer steel plates between different processing units. Before using the high - efficiency powered steel plate clamps, the average time for each transfer operation was about 15 minutes. After the adoption of these clamps, the time was reduced to 5 minutes, resulting in a 66.7% increase in transfer efficiency.

Hot Rolling Mills: In hot rolling mills, the clamps are used to handle hot steel slabs. The adjustable clamping force ensures that the hot steel slabs are securely held during transportation. This has significantly reduced the risk of accidents and product damage. Additionally, the production efficiency has increased by 30% as the clamps can quickly move the steel slabs to the next processing stage.

Continuous Casting Workshops: In continuous casting workshops, the automatic switch function of the clamps has streamlined the production process. Workers no longer need to manually operate the clamps, which has reduced labor intensity and improved production accuracy. The production cycle has been shortened by 25%.

After [Enterprise Name] started using the high - efficiency powered steel plate clamps, the overall production efficiency increased by 40%. In terms of cost reduction, the labor cost was reduced by 30% as fewer workers were needed for plate handling operations. The equipment maintenance cost also decreased by 20% due to the more stable operation of the clamps.

[Enterprise Name] used to have problems with plate misplacement and damage during handling. The high - efficiency powered steel plate clamps solved these problems. The precise movement and adjustable clamping force ensured that the steel plates were accurately placed and securely held, reducing the scrap rate from 5% to 1%.

Compared with traditional clamps, the high - efficiency powered steel plate clamps have obvious advantages. Traditional clamps are usually manual or semi - automatic, which require more labor and time. They also have limited clamping force and less precise movement. In contrast, the powered clamps are fully automatic, with strong and adjustable clamping force, and can achieve precise positioning.

Industry experts believe that the advanced hydraulic drive technology used in these clamps is the key to their high performance. In the future, with the development of the steel industry, the demand for more intelligent and efficient clamps will continue to grow. The high - efficiency powered steel plate clamps are expected to play an even more important role in the industry.

The high - efficiency powered steel plate clamps are truly an indispensable tool for steel production and transportation. They can bring significant cost - reduction and efficiency - improvement effects to steel enterprises. We invite you to share your thoughts and experiences in the comment section below. Do you think these clamps can solve the problems in your steel production process?

If you are interested in learning more about how these high - efficiency powered steel plate clamps can transform your steel production, click here to contact us now!