In the realm of industrial handling, several persistent pain points have long plagued operations. Traditional handling methods often involve complex and time - consuming procedures. Operators may have to spend an average of 15 - 20 minutes per load adjusting and securing the equipment, which significantly slows down the overall workflow. Moreover, steel coils are highly susceptible to damage during handling. Statistics show that approximately 10% of steel coils in industrial settings experience some form of surface damage during the handling process, leading to quality issues and potential losses for businesses.

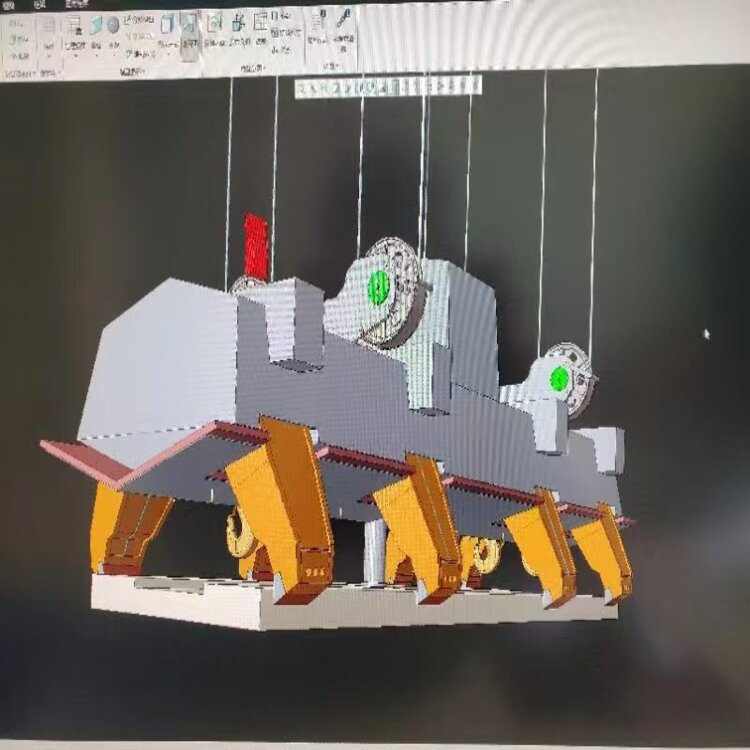

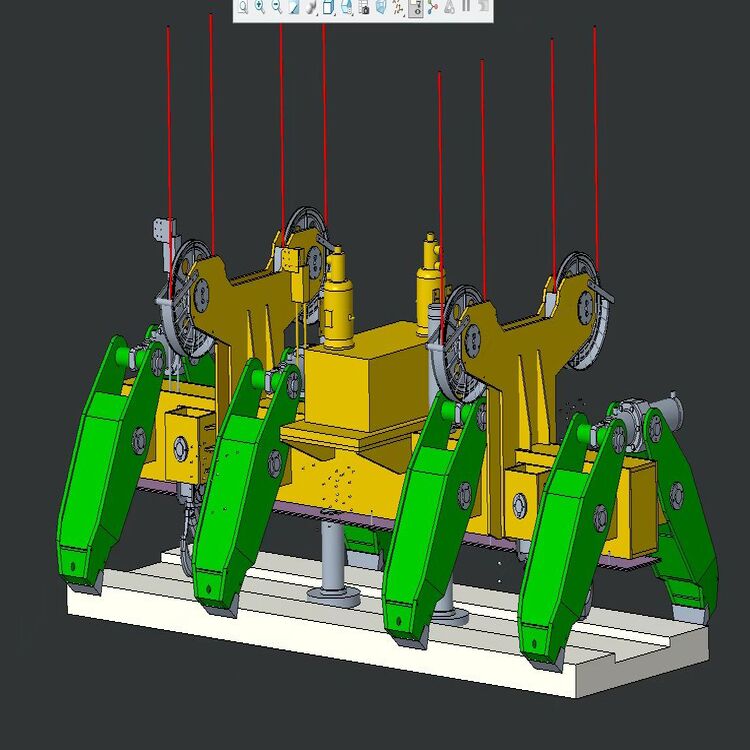

The heavy - duty steel coil clamp is equipped with a revolutionary gravity - operated mechanism. This design simplifies the operation process. Unlike traditional clamps that require multiple steps and manual adjustments, the gravity - operated system allows the clamp to open and close effortlessly. Once the clamp is positioned above the steel coil, gravity takes over, ensuring a quick and secure grip. This reduces the operator's workload and shortens the handling time per load to just 5 - 8 minutes, a significant improvement compared to traditional methods.

Another remarkable innovation is the adjustable support device. Steel coils come in various diameters, and traditional clamps often struggle to accommodate this diversity. The adjustable support device of this clamp can be easily modified to fit different coil diameters. This adaptability makes it suitable for a wide range of industrial applications. Whether dealing with small - diameter coils used in precision manufacturing or large - diameter coils in heavy - duty steel production, the clamp can provide a stable and secure hold.

To address the issue of steel coil damage, the clamp is lined with a special protective filling material. This material acts as a buffer between the clamp and the steel coil, preventing scratches and dents. As a result, the rate of coil damage has been reduced to less than 1%, ensuring the high - quality of the handled products.

Compared with traditional clamps, the innovative design of this heavy - duty steel coil clamp has brought about significant improvements in handling quality and efficiency. The reduction in handling time per load from 15 - 20 minutes to 5 - 8 minutes means that the overall handling capacity can be increased by up to 60%. At the same time, the low coil damage rate ensures that businesses can maintain high - quality product output, reducing waste and potential losses.

Safety is a top priority in industrial operations. The simple and intuitive operation of the clamp reduces the risk of operator errors. Many operators have provided positive feedback. One operator from a large steel plant said, "This clamp has made my job much easier. I no longer have to worry about complex adjustments and potential coil damage. It's a real game - changer."

In a well - known steel production company, after adopting this heavy - duty steel coil clamp, the production line throughput increased by 55% within three months. The company also reported a 90% reduction in coil damage - related losses. These figures clearly demonstrate the effectiveness of the clamp in real - world industrial settings.

In summary, the heavy - duty steel coil clamp offers a range of innovative design features, a wide range of applications, and significant improvements in handling quality and efficiency. It is a reliable solution for various industrial sectors, including steel mills and non - ferrous metal processing plants. If you are looking to enhance your industrial handling operations, don't miss out on this exceptional product. Click here to learn more and take the first step towards a more efficient and high - quality industrial handling process.