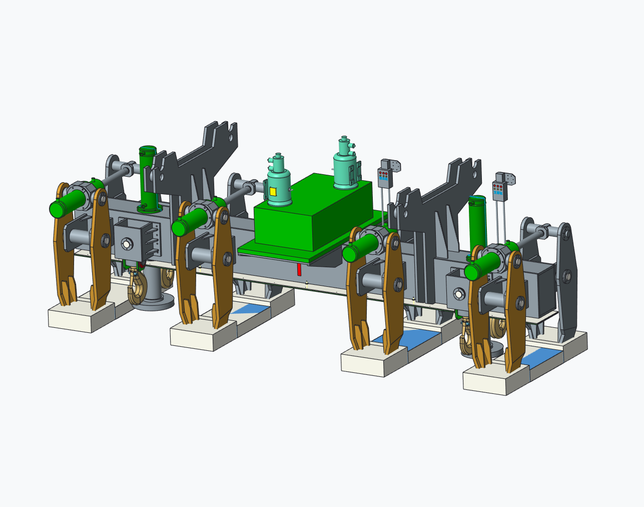

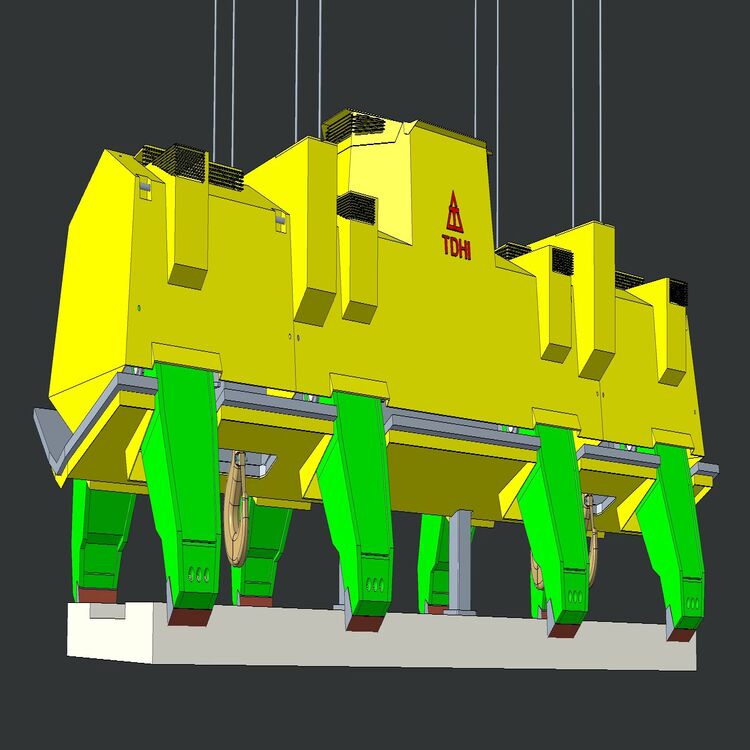

In today’s demanding aluminum production environment, the handling and transportation of aluminum ingots pose critical challenges. Industrial operators face frequent equipment wear, unexpected downtimes, and escalating maintenance costs when using conventional aluminum ingot clamps that fail to meet rigorous operational requirements. Addressing these pain points necessitates clamps that deliver not only precision and safety but also exceptional durability and strength.

Our high-strength aluminum ingot clamps are engineered explicitly to tackle these challenges. Manufactured using premium-grade alloy steel blends with advanced heat treatment technologies, these clamps exhibit superior tensile strength and corrosion resistance compared to typical market alternatives.

Comprehensive lab and field tests confirm the enhanced durability of our clamps. In controlled fatigue testing, the clamps endured over 1.2 million load cycles without structural deformation or loss of clamping force—surpassing industry standards by more than 40%. Salt spray tests verified resistance to corrosive environments, critical for outdoor storage yards.

Moreover, extreme temperature stress simulations exhibited stable performance across a broad range: from -40°C to 80°C, ensuring reliability in diverse climatic conditions encountered worldwide.

Our clamps are widely utilized throughout aluminum processing plants—from initial ingot casting to downstream shipping logistics. Their robust design secures ingots firmly during rigorous handling, minimizing slip risks and reducing potential aluminum material loss due to accidental drops.

Industrial clients report:

| Feature | Our Aluminum Ingot Clamp | Typical Market Clamp |

|---|---|---|

| Load Cycle Endurance | 1.2 million cycles | 850,000 cycles |

| Corrosion Resistance (Salt Spray Test) | Passes 1200 hr | Passes 800 hr |

| Operational Temperature Range | -40°C to 80°C | -20°C to 70°C |

| Average Replacement Cycle | 3 years | 2 years |

A top-tier aluminum manufacturing group in Europe transitioned to our high-strength ingot clamps in early 2023. Over eight months, they reported a striking 25% reduction in maintenance interventions related to clamp wear and failure, while enhancing operational throughput by approximately 12%. The enhanced clamp reliability directly contributed to minimizing unplanned downtime, optimizing labor deployment and reducing indirect costs.

Such real-world validations underscore the strategic value of integrating these durable clamps into aluminum material handling workflows—particularly for businesses prioritizing operational stability and long-term cost efficiency.

To summarize, our clamps offer:

For industrial partners seeking reliable, high-performance aluminum ingot clamps that minimize downtime and maximize equipment longevity, contacting us is the first step toward elevating your operational efficiency.