In the world of heavy lifting, safety and efficiency are paramount. Every year, countless high-altitude lifting accidents occur, causing significant property damage and even endangering human lives. For instance, in a large-scale construction project last year, a traditional lifting device failed during the hoisting of a heavy component at a height of 80 meters. The accident not only led to a halt in the project for several weeks but also resulted in an estimated loss of over $500,000. This kind of incident highlights the urgent need for a reliable and innovative lifting solution. That's where the high-altitude heavy object lifting release beam comes in.

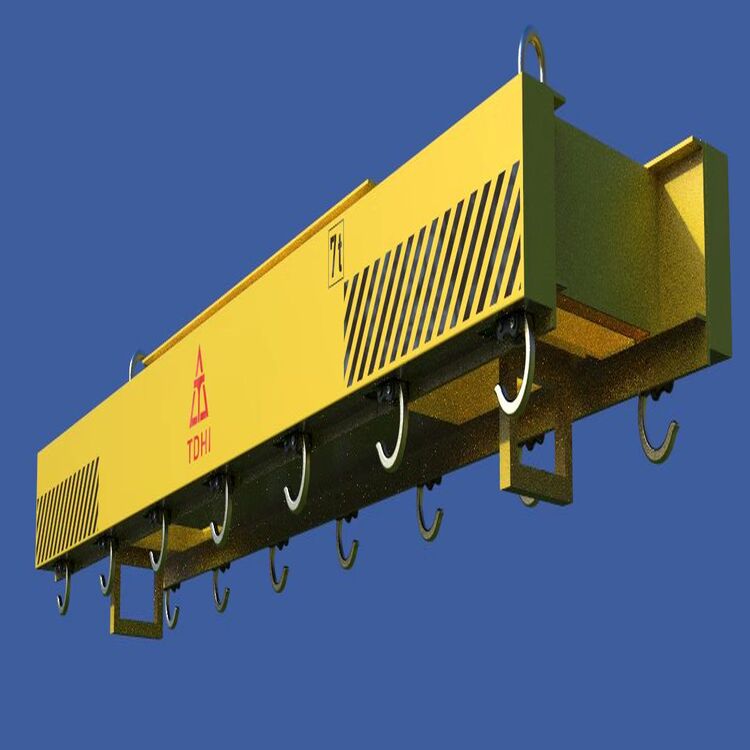

Designed specifically for high-altitude and special lifting scenarios, this lifting release beam combines advanced technology with strict safety principles. One of its most remarkable features is the use of high-strength, lightweight alloy materials. Compared with traditional materials like steel, these alloys offer several significant advantages. Steel, which is commonly used in traditional lifting equipment, is heavy and prone to corrosion, especially in harsh environments. In contrast, the alloy materials used in this lifting release beam are up to 30% lighter, which means less load on the lifting equipment and easier maneuverability. Moreover, they have excellent corrosion resistance, with a corrosion rate that is only 10% of that of steel, ensuring a longer service life even in extreme conditions.

The high-altitude heavy object lifting release beam is a multi-industry workhorse. In the mining industry, it can safely and efficiently lift heavy mining equipment, such as crushers and conveyors, reducing the time required for equipment installation and maintenance by up to 40%. In a large gold mine, after using this lifting release beam, the monthly production capacity increased by 15% due to reduced equipment downtime. In the chemical industry, where the handling of dangerous and heavy chemicals requires high precision and safety, this beam provides a reliable solution. It can accurately position chemical storage tanks, minimizing the risk of spills and accidents.

In the construction industry, it plays a crucial role in high-rise building projects. For example, in a 50-story skyscraper construction, the use of this lifting release beam enabled the construction team to complete the installation of exterior wall panels 20% faster than the original schedule. In the logistics and warehousing sector, it can quickly and safely move large and heavy cargo, improving the overall efficiency of the supply chain. And in maintenance and repair work, it allows technicians to easily access and replace heavy components, reducing the time and effort required for these tasks.

Don't just take our word for it. Many customers have already experienced the benefits of this high-altitude heavy object lifting release beam. A project manager from a construction company said, "Since we started using this lifting release beam, our work efficiency has significantly improved. The lightweight design makes it easy to operate, and the high strength gives us the confidence to handle heavy loads at high altitudes. It has truly become an indispensable tool in our projects." Another customer from the mining industry commented, "The corrosion resistance of this beam is amazing. In our harsh mining environment, it has withstood the test of time and weather, saving us a lot of maintenance costs."

If you're looking for a reliable, efficient, and safe solution to your high-altitude lifting problems, the high-altitude heavy object lifting release beam is the answer. It offers a unique combination of advanced technology, high-quality materials, and multi-industry applicability. To learn more about this innovative product, please visit our official website [Website URL] or contact our sales team at [Contact Email]. We're ready to provide you with detailed information and customized solutions to meet your specific needs.