The aluminum processing industry faces increasing demands to accelerate production cycles while ensuring the highest standards of safety and operational reliability. Rising global competition and stringent safety regulations have pushed manufacturers to seek innovative solutions that not only enhance throughput but also mitigate risks associated with heavy ingot handling and transportation.

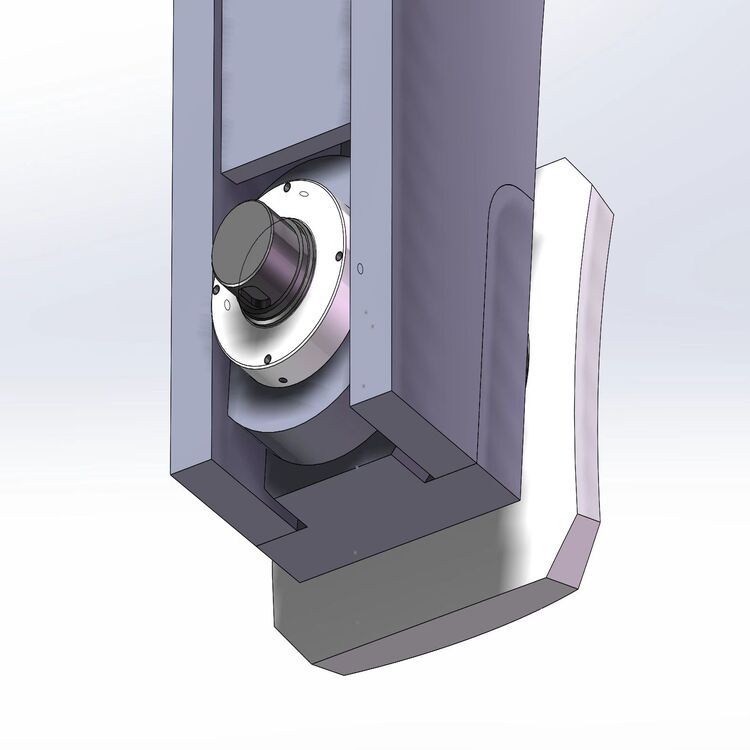

Hydraulic aluminum ingot clamps have emerged as a cornerstone equipment in modern aluminum processing plants. Leveraging hydraulic power, these clamps ensure secure, stable gripping of aluminum ingots during lifting, transport, and storage operations. Their key technical advantages include:

A prominent aluminum processing company, handling over 120,000 tons of aluminum annually, integrated hydraulic aluminum ingot clamps across its production and logistics lines. Prior to implementation, the plant experienced frequent delays due to manual handling inefficiencies and occasional ingot damage during transfer.

After adopting hydraulic clamps, the facility observed a remarkable 18% increase in material handling efficiency. Cycle times for ingot handling decreased from an average of 12 minutes to under 10 minutes per load. Moreover, the incidents of ingot surface damage fell by over 40%, significantly reducing scrap rates and associated costs.

Safety metrics also improved — near-miss reports related to ingot drops dropped from 7 cases per quarter to zero within six months of adoption. The company reported enhanced operator confidence and reduced strain injuries thanks to the ergonomic, powered clamp design.

| Feature | Hydraulic Aluminum Ingot Clamp | Traditional Mechanical Grip |

|---|---|---|

| Clamping Force Consistency | Highly consistent due to hydraulic control | Variable; operator-dependent |

| Load Capacity | Up to 5 tons | Typically less than 3 tons |

| Ease of Operation | Fast, minimal manual effort | Manual adjustment required |

| Safety | Integrated safety locking and pressure monitoring | Limited safety features; higher failure risk |

| Durability | High, suitable for harsh environments | Moderate; prone to wear |

As the aluminum processing sector moves toward greater automation and digital integration, equipment like hydraulic aluminum ingot clamps will play a pivotal role in achieving “smart factory” objectives. Their ability to integrate with IoT-based monitoring systems allows real-time tracking of clamp status and load safety, reducing downtime and maintenance costs.

Industry forecasts suggest that adopting such industrial clamp solutions could enhance overall plant efficiency by up to 25% within the next five years. Companies that proactively implement these technologies will not only boost operational efficiency but also lower workplace risks, thereby strengthening their market competitiveness on a global scale.

Ready to uplift your aluminum processing operations?

Discover how our hydraulic aluminum ingot clamps can enhance efficiency, reduce handling risks, and drive your competitive edge today.

Request a Consultation