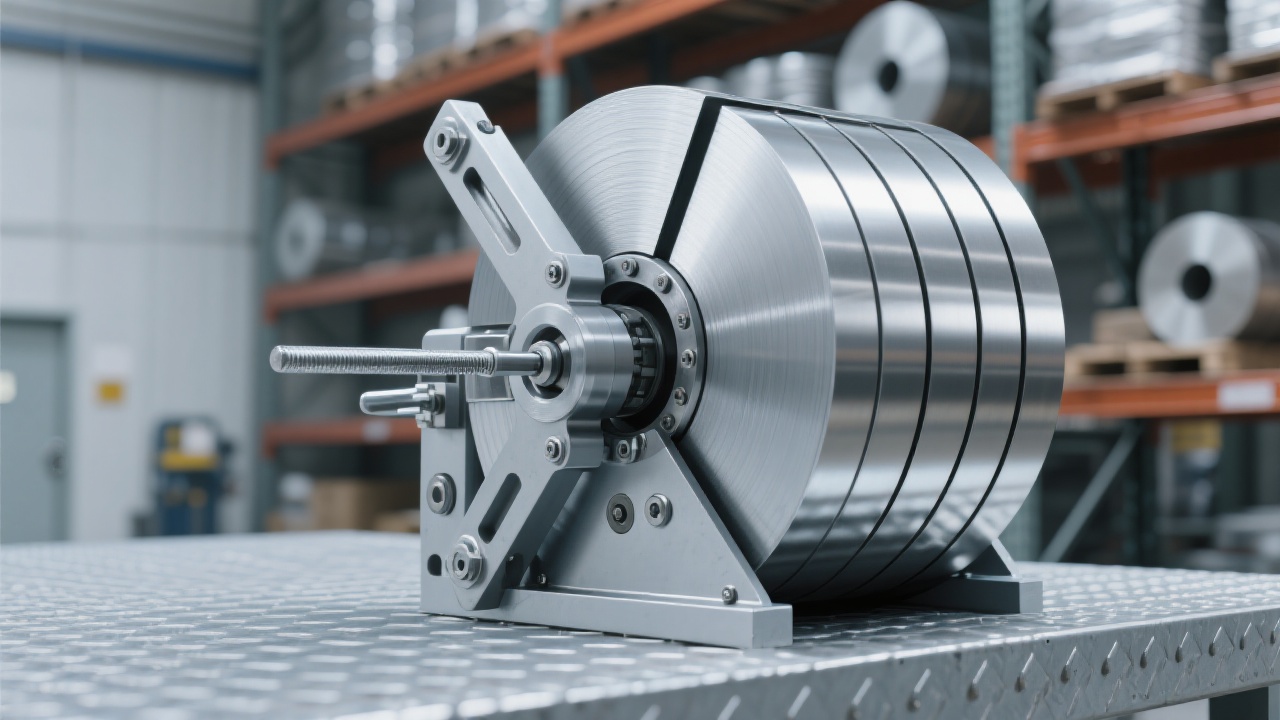

In the realm of industrial heavy-duty handling, efficiency and safety have long been pressing concerns. Traditional steel coil handling methods often face challenges such as low efficiency, potential damage to coils, and high safety risks. However, a revolutionary solution - the roll clamp - has emerged to address these pain points head - on.

The roll clamp features a gravity - operated mechanism and an adjustable support device. The gravity - operated mechanism allows the clamp to securely grip the steel coil with minimal external power input. This not only saves energy but also significantly speeds up the handling process. According to industry data, factories using this roll clamp have reported a 30% increase in steel coil handling efficiency compared to traditional methods.

The adjustable support device is another key innovation. It can be easily adjusted to fit steel coils of different sizes and shapes. This means that a single roll clamp can be used in a wide range of industrial scenarios, eliminating the need for multiple types of handling tools. For example, in a large - scale steel plant, with just a few roll clamps, they can handle steel coils from small - sized ones used in precision manufacturing to large - scale coils for construction purposes.

The roll clamp is equipped with a protective filling material. This material acts as a buffer between the clamp and the steel coil, preventing scratches and other damages during the handling process. In a case study of a steel processing factory, after using the roll clamp with protective filling material, the rate of coil damage decreased from 5% to less than 1%. This not only saves costs associated with damaged products but also ensures the quality of the final products.

One of the most significant advantages of the roll clamp is its user - friendly operation. The controls are simple and intuitive, even for operators with limited experience. A user from a steel mill shared his experience: "I was able to master the operation of the roll clamp within a day. It's so much easier than the old - fashioned handling tools we used before."

In terms of safety, the roll clamp is designed with multiple safety features. For example, it has an automatic locking mechanism that ensures the clamp remains firmly attached to the steel coil during lifting and transportation. This reduces the risk of accidents and provides a safer working environment for operators.

Let's take a look at some real - world applications. In a large steel plant, after implementing the roll clamp, the daily steel coil handling capacity increased from 500 tons to 650 tons. This increase in capacity directly translates to higher production efficiency and greater profitability.

User feedback also speaks volumes about the roll clamp. Many operators have mentioned that the adjustable support device allows them to handle different types of steel coils without the hassle of changing tools. And the protective filling material gives them peace of mind knowing that the coils are well - protected.

In conclusion, the roll clamp offers a comprehensive solution for industrial heavy - duty handling. Its innovative design, including the gravity - operated mechanism, adjustable support device, protective filling material, user - friendly operation, and safety features, makes it an indispensable tool in the steel and related industries. If you are looking to improve the efficiency and safety of your steel coil handling operations, don't miss out on this amazing product. Click here to learn more about the roll clamp and how it can transform your business!