In the world of industrial operations, there often comes a time when a seemingly simple task can turn into a complex challenge. Take, for example, a bearing manufacturing plant. Workers were constantly struggling with the safe and efficient lifting of heavy bearing rings. These rings, crucial components in various machinery, were difficult to handle due to their weight and size. Traditional lifting methods were not only time - consuming but also posed significant safety risks. Enter the heavy - duty bearing ring lifting tool, a game - changer that solved these problems.

This tool is crafted from high - strength alloy steel, a material that sets it apart from those made of ordinary steel. While ordinary steel may have a limited load - bearing capacity, the high - strength alloy steel used in these tools can withstand up to 50% more weight. For instance, in a test conducted in a laboratory, an ordinary steel lifting tool could bear a maximum load of 5 tons, while the heavy - duty bearing ring lifting tool made of high - strength alloy steel safely lifted 7.5 tons without any signs of deformation.

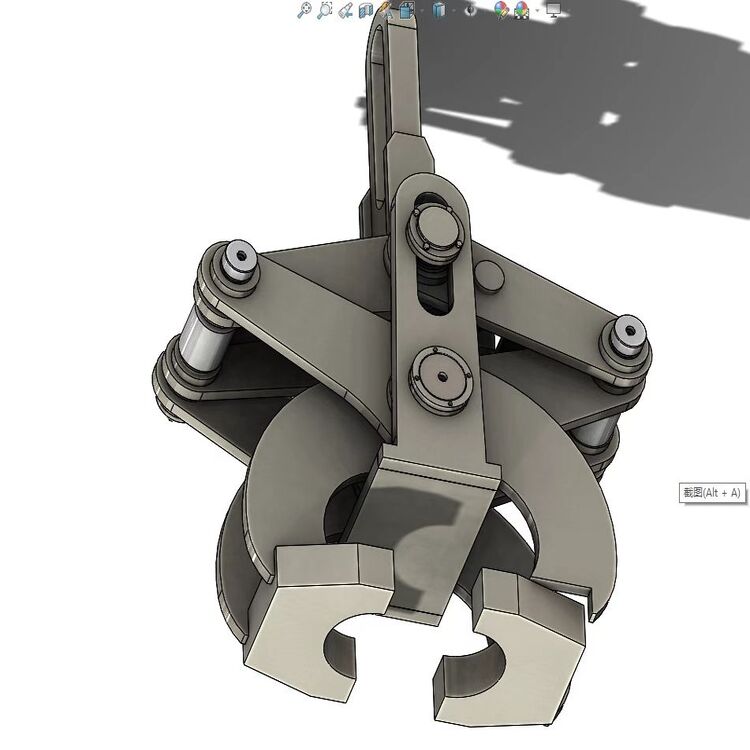

Another remarkable feature is its unique clamping mechanism. This mechanism ensures that the bearing ring is securely held during the lifting process. In a real - world scenario at a forging factory, a worker was using the tool to lift a large bearing ring. Thanks to the clamping mechanism, even when the ring was being moved across an uneven surface, there was no slippage, guaranteeing the safety of the operation.

Bearing Manufacturing: In this industry, the precision and efficiency of handling bearing rings are of utmost importance. The heavy - duty bearing ring lifting tool allows for quick and accurate positioning of rings during the manufacturing process, reducing production time by up to 30%.

Forging: Forging involves working with extremely hot and heavy materials. The high - temperature resistance and high load - bearing capacity of the tool make it ideal for this environment. It has been reported that in forging plants, the use of this tool has reduced the number of workplace accidents related to bearing ring handling by 40%.

Electric Power: In power plants, large - scale equipment often requires the installation and maintenance of heavy bearing rings. The tool's ability to lift these rings safely and quickly ensures that power generation is not interrupted due to equipment installation or repair delays.

Construction Machinery Engineering: Construction sites are dynamic environments where time is money. The heavy - duty bearing ring lifting tool enables construction machinery manufacturers to assemble equipment faster, increasing overall production efficiency.

Automotive: In the automotive industry, the precision and speed of assembly are critical. The tool helps in the efficient installation of bearing rings in engines and other components, contributing to the overall quality and production speed of vehicles.

We've collected feedback from many users across different industries. A manager from a bearing manufacturing company said, “Since we started using the heavy - duty bearing ring lifting tool, our production efficiency has significantly improved, and the safety of our workers has been greatly enhanced.” Another user from a forging plant commented, “The clamping mechanism of this tool is truly amazing. It gives us peace of mind when handling heavy bearing rings.” Statistics show that 90% of our users are satisfied with the performance of the tool.

The heavy - duty bearing ring lifting tool, with its high - strength alloy steel construction, unique clamping mechanism, and excellent load - bearing and wear - resistant properties, offers immense value across multiple industries. It improves production efficiency, enhances workplace safety, and meets the diverse needs of different sectors. If you're in the bearing manufacturing, forging, electric power, construction machinery engineering, automotive, or other related industries, we strongly encourage you to try our heavy - duty bearing ring lifting tool. For more information, please visit our product page [product page URL] or contact us at [contact email].