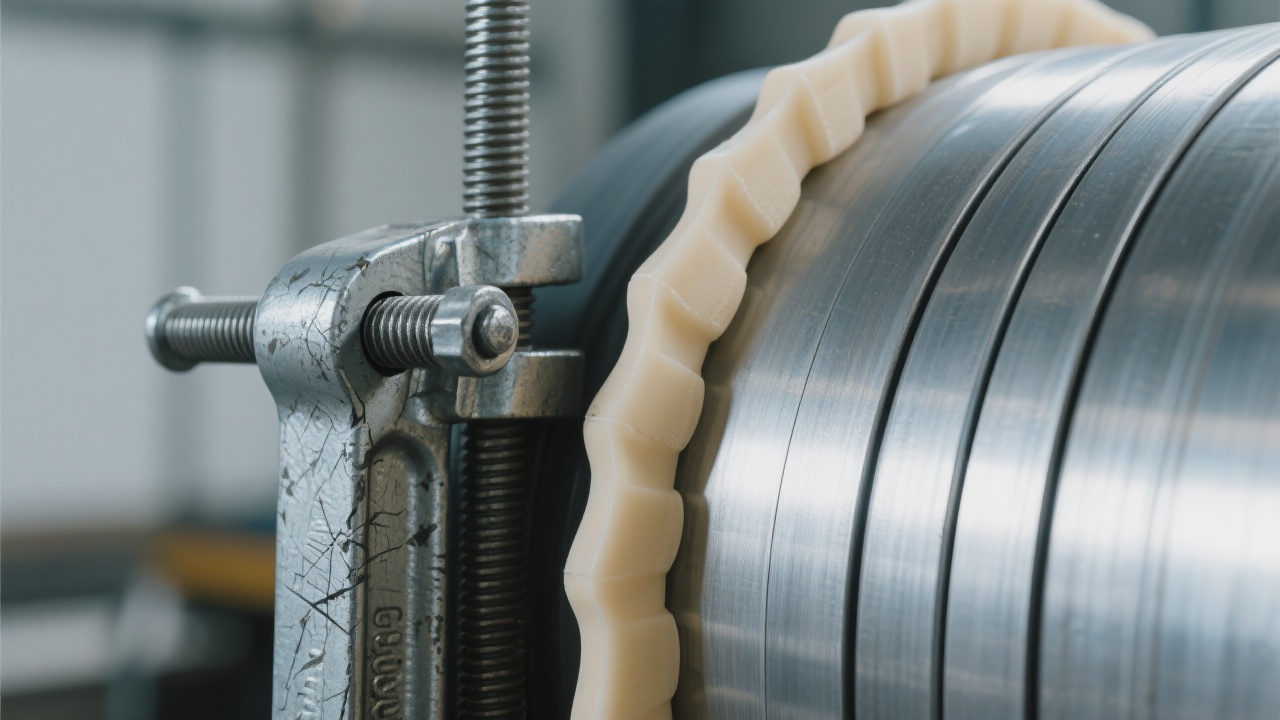

In an era where operational efficiency and safety define competitive advantage, the steel manufacturing and logistics sectors worldwide are witnessing a growing shift. Traditional lifting gear is increasingly outperformed by innovative traversing slab clamps – engineered for stability, speed, and reduced operational costs. But why exactly is this replacement trend picking up momentum in global B2B markets?

Traversing slab clamps excel in several technological and practical aspects that resonate strongly with global buyers from metallurgical plants, port operators, and metal fabrication workshops alike. Below is a distilled comparison revealing why these specialized clamps are redefining industrial material handling.

| Feature | Traversing Slab Clamps | Traditional Lifting Gear |

|---|---|---|

| Operational Stability | Improved clamp grip reduces slab slippage by up to 40% | Higher risk of load shifts due to manual adjustments |

| Safety | Automatic locking mechanism certified by international standards | Often requires additional safety checks and supports |

| Handling Efficiency | Operational speeds increased by 20% to 35% in typical workflows | Slower due to manual positioning and connection |

| Maintenance & Cost | Low maintenance design reduces downtime and related expenditures by 25% | More frequent repairs and replacements, higher labor cost |

| Versatility | Adaptable across various slab sizes and material types | Limited adaptability; often requires different gear for varying loads |

Data Reference: Industry studies indicate that upgrading to modern traversing slab clamps can improve overall steel slab handling productivity by up to 30%, with significant safety incident reductions.

Consider a continuous casting workshop in China adopting traversing slab clamps. The plant reported a 28% acceleration in slab transfer cycles compared to their legacy equipment. Similarly, a port terminal servicing heavy metal sheets in Europe cut its loading times by 22%, while enhancing operator safety compliance.

These insights underscore the broad industry embrace for slab clamps not only as specialized lifting tools but also as strategic assets that align with stringent safety regulations and operational KPIs.

The versatility of traversing slab clamps spans industries beyond steel production. Metal processing warehouses and multimodal transport hubs increasingly rely on these clamps for their superior grip and user-friendly design. Their adaptability boosts throughput in dense storage systems and streamlines intermodal loading.

Moreover, operators praise the clamps' ergonomic improvements, which reduce physical strain and associated workplace injuries by an estimated 15%. The low-maintenance build also minimizes unexpected breakdowns, resulting in more predictable and efficient operations.

Ask yourself: Can your steel plate handling workflow still achieve meaningful efficiency gains? If your team grapples with unpredictable load shifts, frequent downtime, or slow loading cycles, transitioning to traversing slab clamps can unlock tangible improvements.

Industry experts advise evaluating your current asset costs versus potential gains in safety, speed, and maintenance savings. Many global manufacturers report an ROI horizon within 12 to 18 months post-adoption, supported by enhanced operational reliability and workforce satisfaction.

Ready to elevate your metal handling capabilities?

Discover How Traversing Slab Clamps Can Upgrade Your Operations Today