In the steel production industry, the demand for efficient and safe handling of steel plates has always been a top priority. High-efficiency power-type steel plate clamps with advanced hydraulic drive technology have emerged as a revolutionary solution to meet these needs. This article delves into the details of this remarkable technology and its wide-ranging applications.

As the steel industry continues to evolve, traditional methods of handling steel plates are gradually becoming less efficient and more prone to safety risks. The development of high-efficiency power-type steel plate clamps with hydraulic drive technology is a significant step forward. This technology enables these clamps to operate with greater precision and reliability, which is crucial for modern steel production facilities.

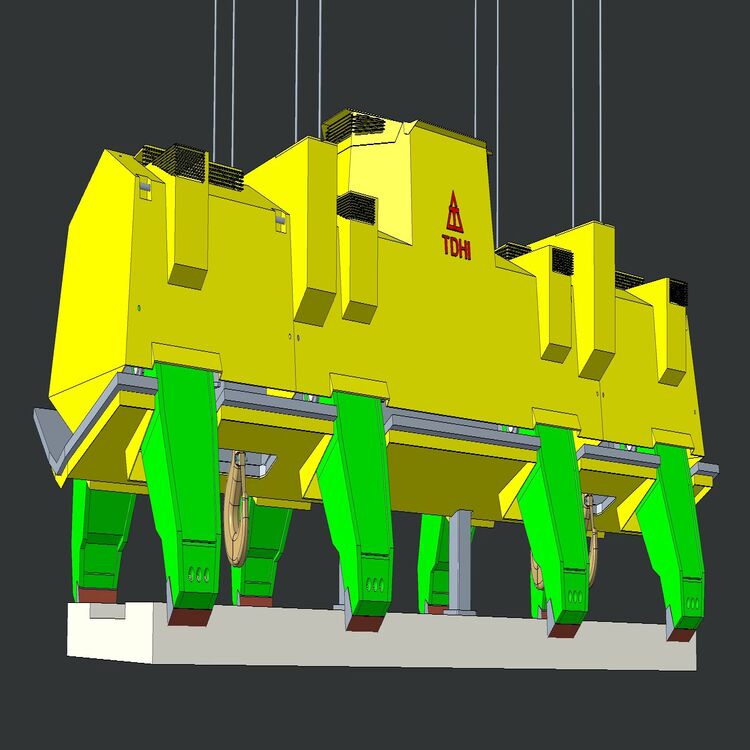

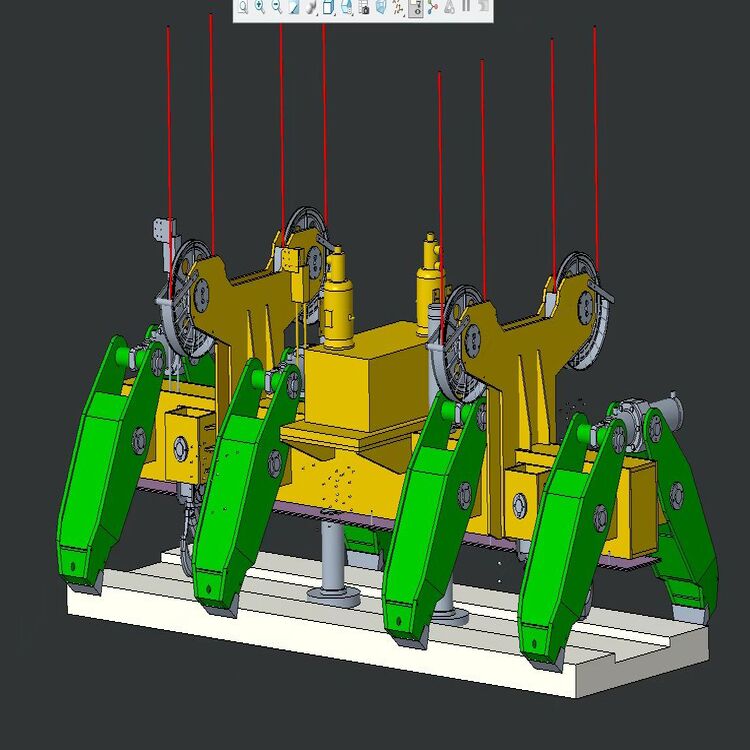

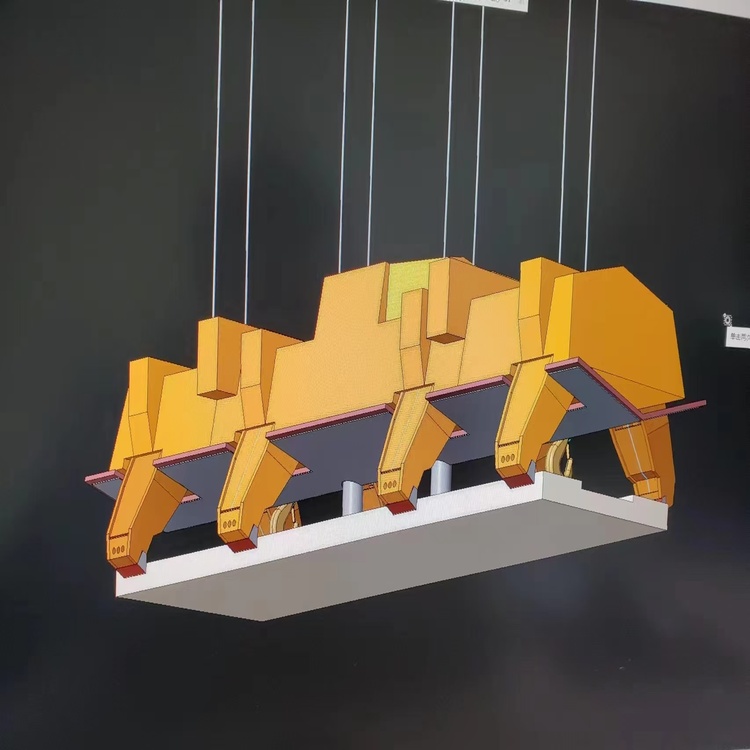

The core of the high-efficiency power-type steel plate clamp lies in its advanced hydraulic drive mechanism. This mechanism works on the principle of using hydraulic pressure to generate force. The hydraulic system can precisely control the movement of the clamp, allowing it to move accurately to the desired position. Moreover, it provides an adjustable clamping force. For example, in different steel production scenarios, the clamping force can be adjusted from 5 tons to 20 tons according to the weight and size of the steel plates. This ensures that the steel plates are securely held during handling, reducing the risk of accidents.

These clamps have found extensive applications in various steel production scenarios:

Compared with traditional clamps, high-efficiency power-type steel plate clamps with hydraulic drive technology have several significant advantages. Traditional clamps often lack the precision in movement and adjustable clamping force. They are also more labor-intensive and less suitable for handling large and heavy steel plates. In contrast, the new clamps can operate automatically, reducing human error and labor costs. They can also handle a wider range of steel plate sizes and weights, improving overall production flexibility.

Industry experts have recognized the potential of this technology. They believe that the hydraulic drive technology in these clamps represents the future direction of steel plate handling. As the steel industry continues to demand higher efficiency and safety, this technology will be further developed and optimized. For example, experts predict that in the next five years, the accuracy of the clamping force adjustment will be improved by another 15%.

Many enterprises have benefited from using these clamps. A medium-sized steel enterprise in Europe was facing challenges with slow production and high accident rates due to the use of traditional clamps. After switching to high-efficiency power-type steel plate clamps, they not only improved their production efficiency by 28% but also significantly reduced the number of safety accidents. This not only saved costs but also enhanced their competitiveness in the market.

In conclusion, high-efficiency power-type steel plate clamps with advanced hydraulic drive technology offer significant value to the steel production industry. They can greatly improve production efficiency, reduce costs, and enhance enterprise competitiveness. We invite you to share your thoughts on this technology in the comments section below. If you are interested in learning more about how these clamps can benefit your business, please contact us today. Take the first step towards revolutionizing your steel plate handling process!