Unveiling Major Challenges in Mining Operations: Comprehensive Analysis of Multi-Functional Lifting Tool Solutions

Mining operations face critical challenges in heavy load handling, including safety risks, extended downtime, and efficiency limitations. The high-altitude heavy load lifting release beam, a multi-functional lifting tool crafted from high-strength, lightweight alloy materials, offers a versatile solution applicable across mining and other industrial sectors. By enhancing operational safety, boosting productivity, and minimizing downtime, this tool addresses key mining pain points effectively. This article provides an in-depth examination of the lifting tool’s features, supported by data and case studies, demonstrating its potential to transform mining workflows by elevating efficiency, reducing risk, and increasing overall profitability.

Unveiling the Core Challenges in Mining Operations and the Multi-Functional Lifting Tool Solution

Mining operations worldwide consistently grapple with significant challenges in heavy load handling—where safety concerns, operation inefficiencies, and extended downtime converge to impact productivity and profitability. According to industry reports, up to 25% of operational delays in underground and open-pit mining stem from material handling inefficiencies and equipment downtime. Addressing these pain points requires innovative tools that not only streamline process workflows but also enhance worker safety and operational reliability.

The Mining Industry’s Persistent Pain Points

Heavy material lifting in mining environments is fraught with risks due to the sheer weight and awkward dimensions of equipment and extracted materials. Common obstacles include:

- Safety Risks: Inadequate lifting tools increase the risk of accidents, resulting in injuries and costly operational halts.

- Efficiency Losses: Traditional lifting methods often require manual intervention and prolonged cycle times.

- Downtime: Mechanical failures or improper rigging can significantly lengthen downtime, reducing overall site productivity.

- Material Damage: Mishandling during lifting can damage expensive mining equipment and extracted minerals, impacting bottom-line returns.

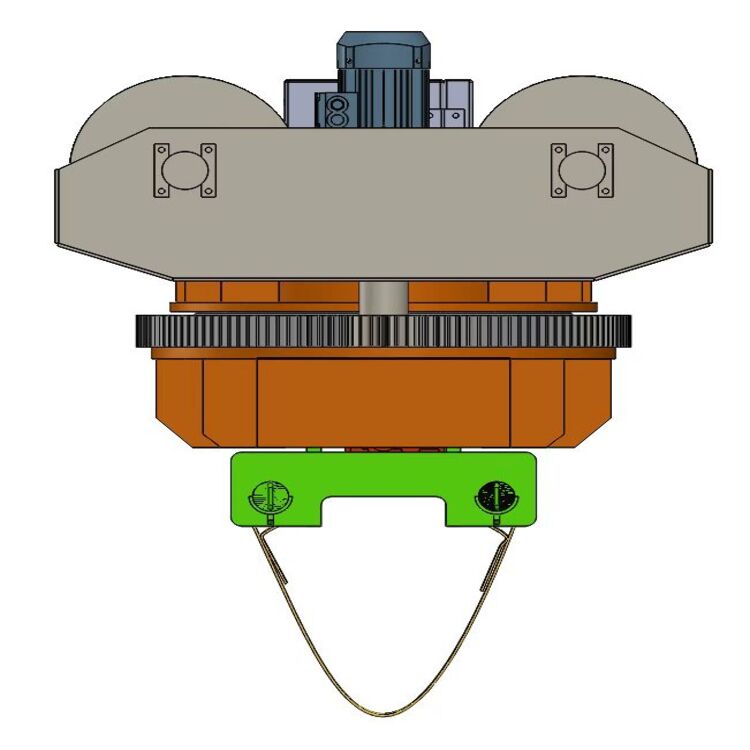

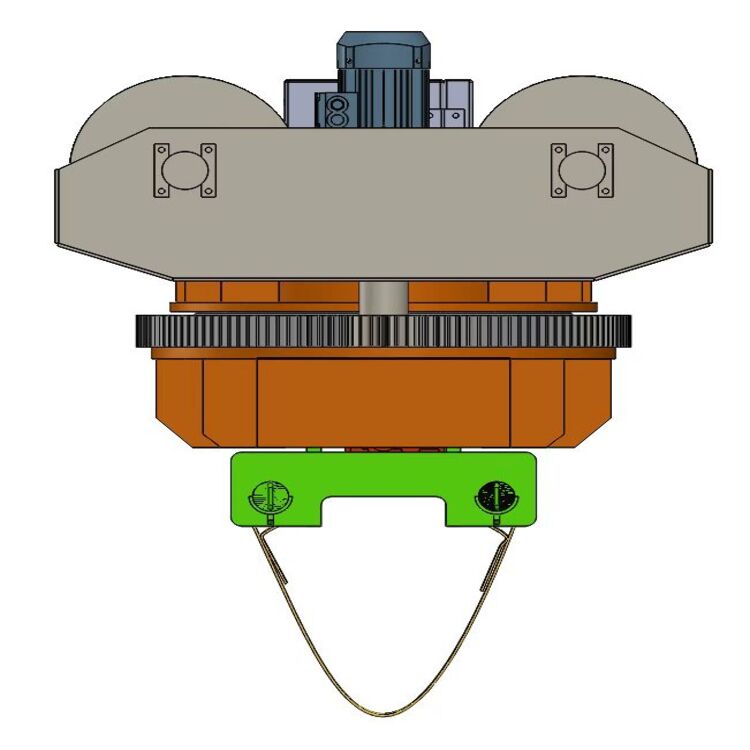

Introducing the High-Altitude Heavy Load Release Beam: A Versatile Lifting Tool for Mining

The high-altitude heavy load release beam emerges as a multi-functional solution designed specifically to meet these challenges. Constructed from advanced high-strength, lightweight alloy materials, this tool delivers exceptional durability without compromising maneuverability—an essential feature in confined or elevated mining environments.

By integrating this release beam into lifting operations, mining companies can:

- Enhance Safety: The tool’s reliable locking and releasing mechanisms ensure secure handling of heavy loads, minimizing human error.

- Boost Efficiency: Quick attachment and release reduce cycle times by up to 30%, accelerating material handling workflows.

- Reduce Downtime: The robust alloy composition provides high resistance against wear and corrosion, lowering maintenance frequency.

- Increase Flexibility: Adaptable for a variety of load shapes and sizes common in mining, including oversized equipment components.

Case Study: Operational Gains from Adopting the Release Beam in Mining Sites

A leading mining operator in South America integrated the high-altitude heavy load release beam into their daily workflows for handling processing equipment. Within six months, they recorded:

| Performance Metric | Pre-Implementation | Post-Implementation |

| Lifting Cycle Time | 45 minutes | 31 minutes (31% reduction) |

| Maintenance Frequency | Monthly inspections and repairs | Quarterly inspections (reduced by 66%) |

| Safety Incidents | 3 reported events in first quarter | 0 incidents recorded |

This case clearly illustrates the release beam’s tangible impact on site safety, operational uptime, and cost-efficiency.

Why Global Procurement Leaders Should Prioritize This Multi-Functional Lifting Tool

Mining procurement professionals face increasing pressure to source innovative solutions that improve productivity while ensuring compliance with evolving safety standards. The high-altitude heavy load release beam aligns with these strategic objectives by offering:

- Proven Safety Enhancements: Solid engineering and stringent quality control ensure trustworthiness under demanding conditions.

- Material Efficiency: Lightweight alloys reduce handling strain, which translates into less worker fatigue and increased operational tempo.

- Multi-Industry Compatibility: Beyond mining, the tool’s design suits construction, energy, and heavy manufacturing sectors, broadening procurement ROI.

- Lifecycle Durability: Corrosion-resistant materials translate to long service life, balancing upfront investment with enduring value.

Ready to elevate your mining operations to new standards of safety and efficiency?

Contact our expert team today to explore how the high-altitude heavy load release beam can reduce downtime, mitigate risk, and boost productivity on your sites.