In the realm of the steel industry's logistics, the high-efficiency steel plate grabber has emerged as a revolutionary tool. This article delves deep into the innovative technologies of its high-strength alloy steel clamps, exploring how they bring significant improvements to the steel logistics process.

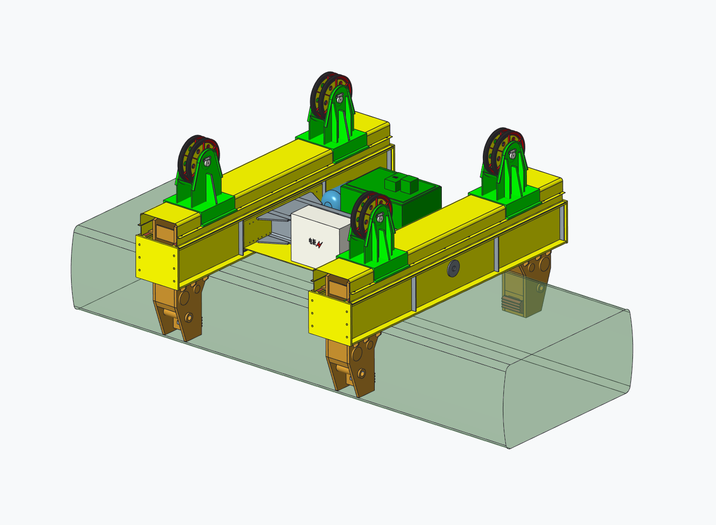

The high-efficiency steel plate grabber has become an indispensable part of the steel industry's logistics chain. In a typical steel manufacturing plant, the transportation and handling of steel plates account for a large proportion of the overall logistics time. Traditional handling methods are not only inefficient but also pose potential safety risks. The high-efficiency steel plate grabber, with its advanced design and high-performance clamps, has changed this situation fundamentally.

The high-strength alloy steel used in the grabber's clamps offers numerous advantages. Firstly, it has excellent strength and toughness. Tests have shown that compared with ordinary steel clamps, high-strength alloy steel clamps can withstand up to 30% more pressure without deformation. This means they can securely hold heavy steel plates during the handling process, reducing the risk of dropping and damage. Secondly, the alloy steel has good corrosion resistance, which is crucial in the often harsh environments of steel factories. A study found that in a humid and corrosive environment, high-strength alloy steel clamps maintained their performance for up to 5 years, while ordinary steel clamps started to show signs of corrosion and reduced functionality within 2 years.

One of the key innovative highlights of the high-strength alloy steel clamps is the application of the lever principle. This design allows the grabber to exert a large clamping force with relatively little input force. By optimizing the lever structure, the clamping force can be increased by up to 40% compared to traditional designs. Moreover, the automatic opening and closing mechanism enhances the operational efficiency significantly. In a steel factory, workers can operate the grabber to open and close the clamps with just a simple button press, reducing the manual labor intensity and saving a lot of time. In actual operations, the time required for each handling cycle has been reduced by about 20% after using the grabber with this mechanism.

The high-efficiency steel plate grabber has a wide range of applications in different scenarios. In steel manufacturing plants, it can quickly and safely transfer steel plates from the production line to the storage area. In hot-rolling mills, it can handle high-temperature steel plates without being affected by the heat. For example, in a large-scale hot-rolling mill, the grabber has been used to handle more than 10,000 steel plates in a month, with an extremely low error rate of less than 0.1%, which fully demonstrates its reliability and efficiency.

Let's take a look at a real - world case. A medium - sized steel company introduced the high - efficiency steel plate grabber. Before using it, the daily handling capacity of steel plates was about 500 tons, and the accident rate was about 1%. After using the grabber, the daily handling capacity increased to 700 tons, an increase of 40%. At the same time, the accident rate dropped to 0.2%, which greatly improved the logistics efficiency and ensured the safety of operations.

In conclusion, the high - efficiency steel plate grabber with its high - strength alloy steel clamps is a game - changer in the steel industry's logistics. It offers significant advantages in terms of material properties, innovative design, and practical applications. The high - strength alloy steel clamps ensure the reliability and durability of the grabber, while the innovative technologies improve the operational efficiency and safety. The high - efficiency steel plate grabber is the top choice for the steel industry to enhance logistics efficiency and ensure operational safety. If you are looking to upgrade your steel logistics operations, don't miss out on this amazing product. Contact us now to learn more!