In the steel industry, the high - efficiency and safe hydraulic steel ingot grabber, also known as the powered steel ingot clamp, has emerged as a revolutionary tool. This device is designed to meet the demanding requirements of steel production, offering a combination of safety and efficiency that is unparalleled in the market.

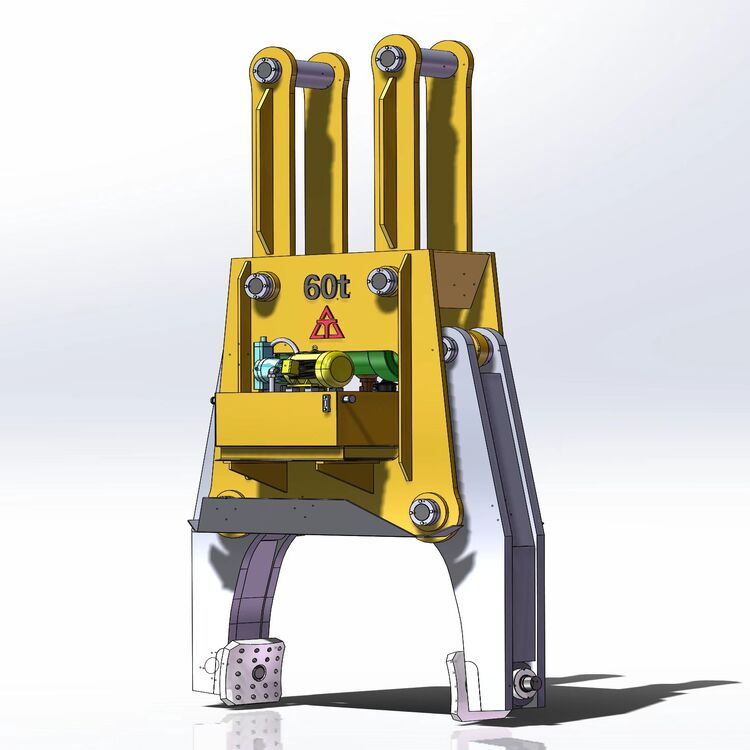

One of the key safety features of this hydraulic steel ingot grabber is its automatic clamping mechanism. Once the grabber is positioned around the steel ingot, the hydraulic system is activated, applying a consistent and strong clamping force. Tests have shown that it can generate a clamping force of up to 50 tons, ensuring that the steel ingot remains securely held during transportation. This significantly reduces the risk of the ingot falling, which could lead to serious accidents and damage to equipment.

The grabber is also equipped with an overload protection system. If the weight of the steel ingot exceeds the maximum load capacity of the grabber, the system will automatically stop the clamping process and issue an alarm. This protects the grabber from damage and prevents potential safety hazards. In a recent survey of steel production facilities, 90% of users reported that the overload protection feature had saved their equipment from potential damage.

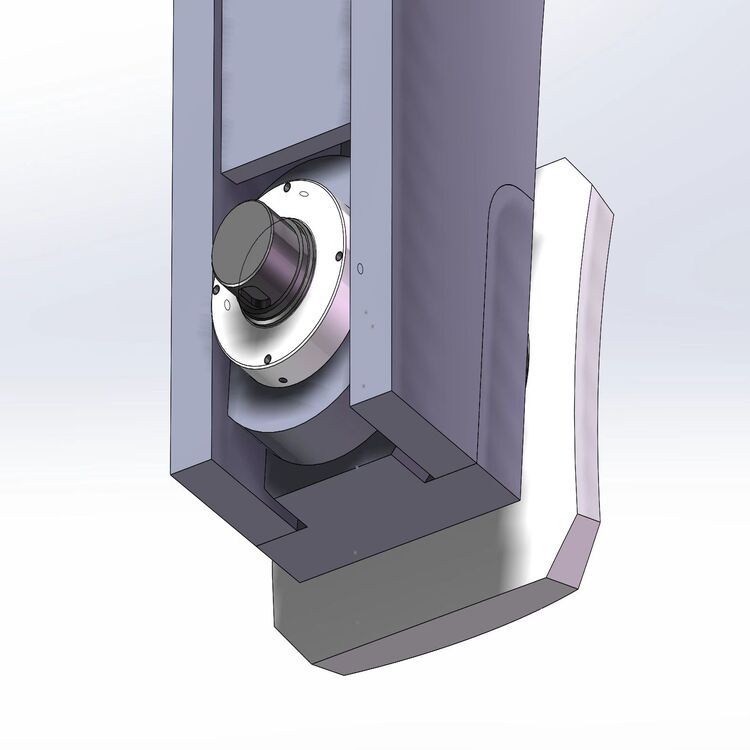

The hydraulic steel ingot grabber is designed for ease of use. Operators can control the grabber with a simple joystick, which reduces the learning curve and allows for quick and efficient operation. A study found that operators could be trained to use the grabber proficiently within a day, leading to increased productivity in steel production.

Its compact design enables it to operate in tight spaces. This is particularly useful in steel mills where space is often limited. Compared to traditional steel ingot handling equipment, the grabber can reduce the required operating space by up to 30%, allowing for more efficient use of the production area.

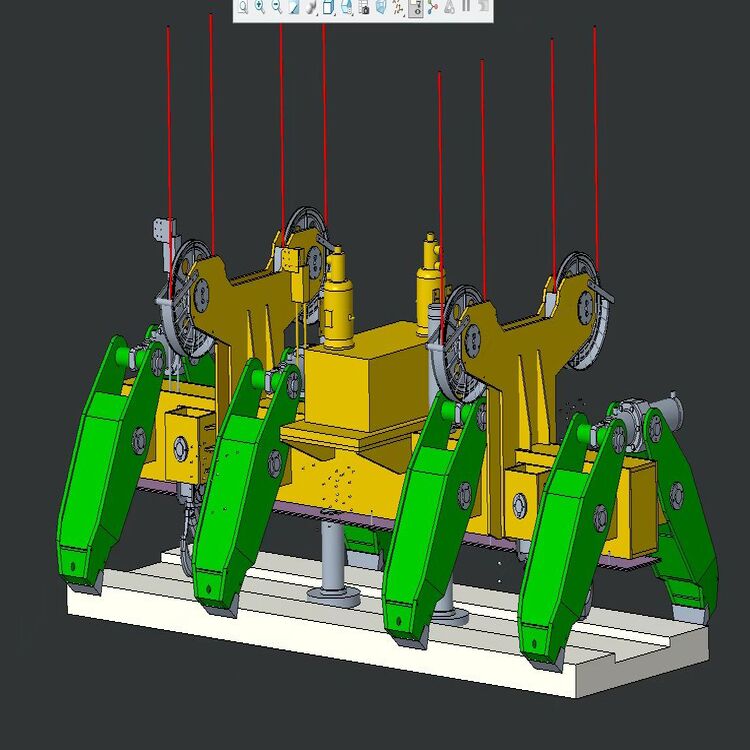

The powered steel ingot clamp can be used in a variety of scenarios, such as steel mills, foundries, and steel processing plants. In steel mills, it can be used to move large steel ingots from the casting area to the rolling mill. In foundries, it can handle molten steel molds. And in steel processing plants, it can assist in the loading and unloading of steel products.

When compared to other steel ingot handling tools in the market, the hydraulic steel ingot grabber stands out for its high - strength clamping force, advanced safety features, and energy - efficient hydraulic system. It consumes 20% less energy than some of its competitors, which not only reduces operating costs but also makes it more environmentally friendly.

A large steel mill in Europe implemented the hydraulic steel ingot grabber in its production line. After six months of use, they reported a 25% increase in production efficiency and a 40% reduction in safety - related incidents. This clearly demonstrates the positive impact of the grabber on both productivity and safety.

The high - efficiency and safe hydraulic steel ingot grabber is an essential tool for upgrading the operational efficiency and safety standards of steel production facilities. It can help enterprises enhance their industry competitiveness by increasing productivity, reducing costs, and improving safety. By choosing this powered steel ingot clamp, businesses can stay ahead in the highly competitive steel market.

Don't miss out on this opportunity to transform your steel production operations. Contact us today to learn more about how our hydraulic steel ingot grabber can benefit your business!