In the competitive domain of steel manufacturing and transport, efficiency and safety on handling molten steel ingots represent critical operational priorities. Powered steel ingot clamps have emerged as indispensable tools, leveraging advanced hydraulic technology to ensure secure, swift, and dependable steel ingot manipulation. This article delves into the technical principles behind these clamps, highlights their safety features, and explores how they contribute to enhancing operational efficiency, ultimately empowering enterprises to strengthen their market competitiveness.

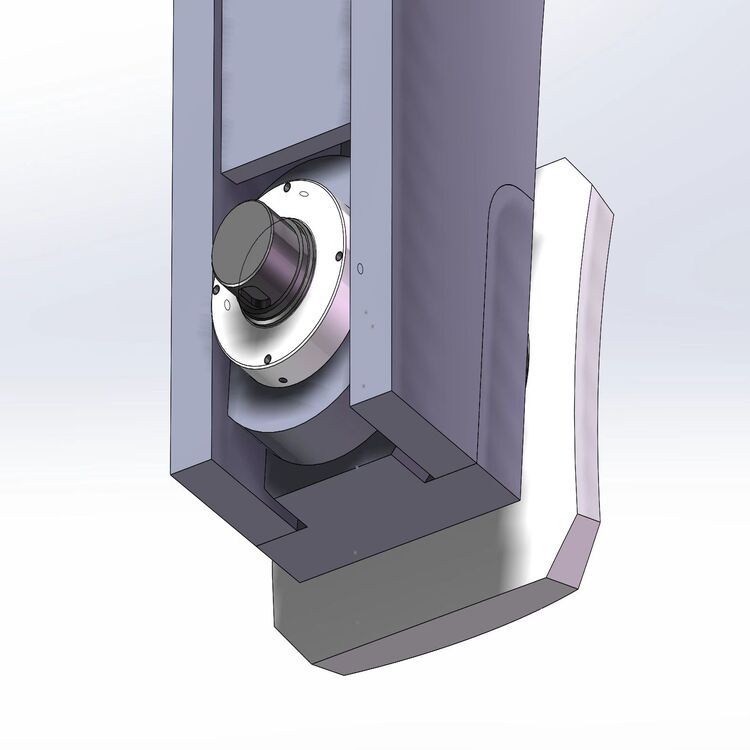

At the heart of powered steel ingot clamps lies a precision-engineered hydraulic system designed to exert consistent and controllable gripping force. This automatic clamping mechanism operates through high-pressure hydraulic cylinders that modulate the jaw force dynamically. A typical clamp can generate gripping forces surpassing 20,000 Newtons, which is critical to safely holding heavy steel ingots weighing upwards of several tons during transfer. The hydraulic drive ensures smooth, responsive operation, reducing the risk of slippage or accidental release, thereby safeguarding personnel and equipment.

The safety credentials of powered steel ingot clamps are underpinned by their robust, compact construction and redundant safety systems. Key features include:

These design considerations culminate in a clamp that not only adheres to stringent industrial safety standards—such as ISO 12100 for machine safety—but also facilitates operator confidence and reduces workplace accidents by over 30%, as documented in steel plant safety audits.

Besides safety, the powered steel ingot clamp excels in enhancing throughput and operational fluidity. Its compact design enables seamless integration with overhead cranes and automated handling systems, optimizing workflow in constrained factory layouts. Operational benefits include:

| Feature | Operational Impact |

|---|---|

| Automatic Load Sensing | Adjusts clamping force in real-time, reducing cycle time by up to 15% |

| Intuitive Control Interface | Minimizes operator training time and error rates |

| Low Maintenance Engineering | Increases clamp uptime, boosting labor efficiency by approximately 10% |

Industry case studies reveal that companies adopting powered steel ingot clamps experience measurable efficiency gains while effectively minimizing downtime and safety incidents. For example, a major steel producer in Europe reported a 20% improvement in ingot handling speed alongside a 35% decline in workplace injuries after full implementation.

Powered steel ingot clamps embody a strategic investment that aligns with the modernization and automation objectives of contemporary steel plants. By integrating advanced hydraulic clamping technology, enterprises can stabilize production flows, reduce manual labor risks, and expedite material handling cycles—key factors that collectively elevate throughput and cost-effectiveness.

Furthermore, enhanced safety compliance and process reliability directly contribute to regulatory adherence and corporate sustainability goals, reinforcing stakeholder confidence and unlocking new market opportunities.