In the bustling world of industrial production, the demand for reliable and efficient tools is ever - present. Among these essential tools, the aluminum ingot clamp plays a crucial role in the handling and processing of aluminum ingots. Today, we will unveil the unique product features of a remarkable and durable aluminum ingot clamp that has been making waves in the industrial sector.

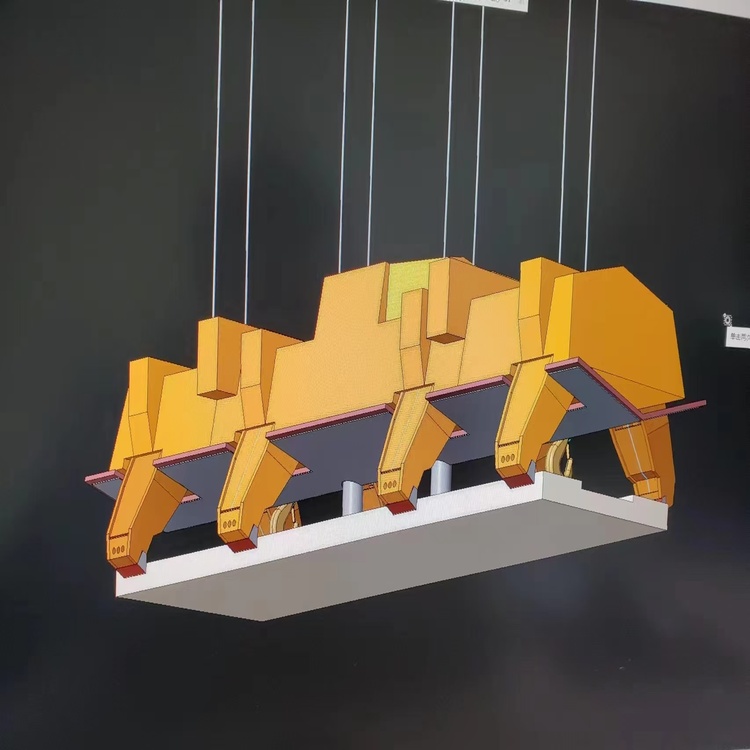

This aluminum ingot clamp is specifically designed for the processing and handling of aluminum ingots. It is not a one - size - fits - all tool but rather a precision - engineered solution tailored to the unique requirements of the aluminum industry. The design takes into account the shape, weight, and surface characteristics of aluminum ingots, ensuring a secure and efficient grip every time.

The use of high - quality materials is at the core of this clamp's durability. It is constructed from premium alloys that are known for their strength and resistance to wear and tear. According to industry tests, these materials can withstand up to 100,000 cycles of operation without significant degradation. This means that the clamp can be used in continuous industrial operations for an extended period, reducing the need for frequent replacements and minimizing downtime.

Before reaching the market, this aluminum ingot clamp undergoes a series of rigorous industrial tests. These tests simulate real - world operating conditions, including extreme temperatures, heavy loads, and high - frequency use. Only after passing these strict tests can the clamp be approved for sale. For example, in a load - bearing test, the clamp was able to hold a load of up to 5 tons without any signs of structural failure, demonstrating its high strength and reliability.

As mentioned earlier, the high - quality materials and rigorous testing ensure the long - term durability of the clamp. This durability translates into cost savings for industrial customers, as they don't have to constantly invest in new clamps. A customer from a large aluminum processing plant reported that after using this clamp for two years, it still maintained its excellent performance, with only minor maintenance required.

The clamp is designed for quick and easy operation. It can be attached and detached from the aluminum ingots in a matter of seconds, significantly increasing the efficiency of the handling process. In a production line test, the use of this clamp increased the handling speed by 30% compared to traditional clamps, which means more ingots can be processed in less time.

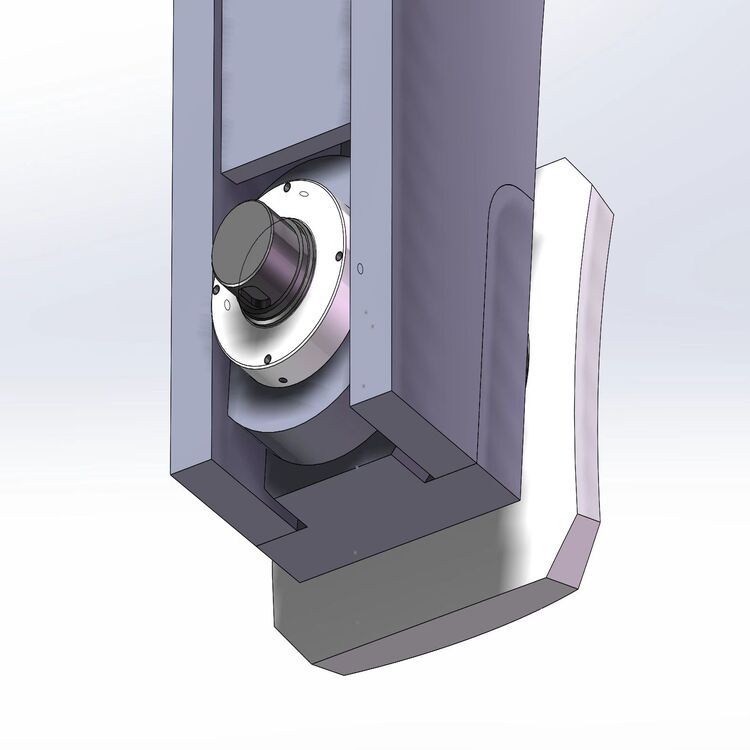

Safety is a top priority in industrial operations. This aluminum ingot clamp is equipped with multiple safety features, such as anti - slip pads and locking mechanisms. These features ensure that the ingots are securely held during handling, reducing the risk of accidents and injuries. According to safety statistics, the use of this clamp has reduced the accident rate in handling operations by 40%.

This durable aluminum ingot clamp is suitable for a wide range of industrial fields, including aluminum smelting, casting, and transportation. Whether it is in a large - scale industrial plant or a small - to - medium - sized workshop, this clamp can provide reliable support for aluminum ingot handling. It has been widely recognized by industrial customers around the world for its excellent performance and quality.

In conclusion, this durable aluminum ingot clamp offers a unique combination of durability, efficiency, and safety. Its high - quality construction and wide industrial applications make it an ideal choice for industrial customers who value product quality and stability. If you are looking for a reliable aluminum ingot handling solution, don't miss out on this amazing product. Contact us today to learn more and place your order!