In the metal processing industry, the efficiency of steel plate handling directly impacts the smoothness of the cutting process and production safety. This article delves into how the high - efficiency translational slab clamp optimizes the entire handling operation from storage to pre - cutting through its advanced transmission mechanism, stable gripping ability, and user - friendly design. Whether in steel mills, manufacturing workshops, or port yards, it can significantly reduce downtime, enhance operational safety, and improve job flexibility. It is a cost - effective solution for multiple industries.

The translational slab clamp has a wide range of applications. In hot - rolling mills, it is used to transfer large - scale steel slabs from the production line to the storage area. At docks, it helps load and unload steel plates from ships, ensuring the rapid and safe movement of goods. In processing workshops, it can quickly move steel plates to the cutting area, improving the overall processing efficiency.

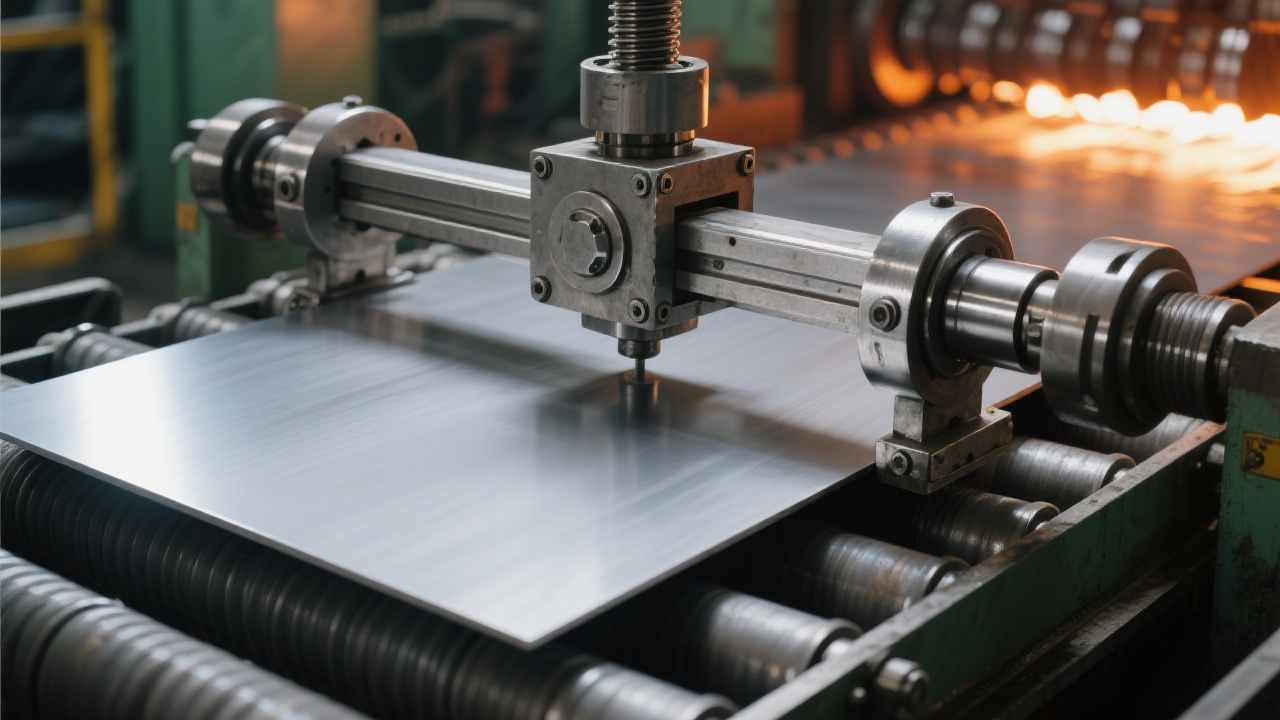

Traditional clamps often suffer from several pain points. They are prone to slippage, which can lead to safety accidents. The adjustment process is slow, causing long downtime during operation. Frequent maintenance is also required, increasing the overall cost. In contrast, the translational slab clamp has made significant technical breakthroughs. It uses an advanced transmission mechanism that provides a stable and strong gripping force, effectively preventing slippage. The adjustment is quick and easy, reducing the time wasted on setup.  A comparison chart (as shown in the figure) clearly shows the advantages of the new clamp over traditional ones.

A comparison chart (as shown in the figure) clearly shows the advantages of the new clamp over traditional ones.

Let's look at some real - life cases. A steel processing plant in [Location] adopted the translational slab clamp and saw a 30% increase in handling efficiency. The accident rate decreased by 40% because of the stable gripping and improved safety features. According to a customer feedback quote: "Since we started using the translational slab clamp, our production line has become much more efficient, and the number of safety incidents has dropped significantly." These data and real - life examples demonstrate the effectiveness of the product in improving efficiency and reducing risks.

This clamp can adapt to a wide range of steel plate specifications. Its unique design allows it to adjust to different plate thicknesses and widths without complex settings. This means that operators can quickly master the operation of the clamp, reducing the training cost. In fact, the training time for new operators has been reduced by 50% compared to using traditional clamps.

To help readers evaluate their own handling process bottlenecks, here are some actionable improvement suggestions. First, conduct a detailed analysis of the current handling process, including the time taken for each step, the frequency of accidents, and the types of steel plates handled. Then, compare the performance of the current clamps with the translational slab clamp. If the current clamps have the problems mentioned above, it is time to consider an upgrade. You can also calculate the potential cost savings and efficiency improvements based on the data provided in this article. By doing so, you can make an informed decision to optimize your steel plate handling process.

In conclusion, the translational slab clamp is a solution that can solve the pain points in steel plate handling, save time, and improve safety. It is suitable for multiple industries and can bring significant benefits to metal processing enterprises. If you want to optimize your steel plate handling process, click here to learn more about this amazing product.