In the industrial heavy-lifting arena, metallurgical plants continually seek reliable, efficient, and safe tools to handle steel coils and heavy rolls. A growing number of these facilities now turn to gravity-operated roll clamps as their go-to equipment for such demanding applications. This article delves into the core mechanics and advantages that position gravity-operated roll clamps as indispensable in modern metal processing environments.

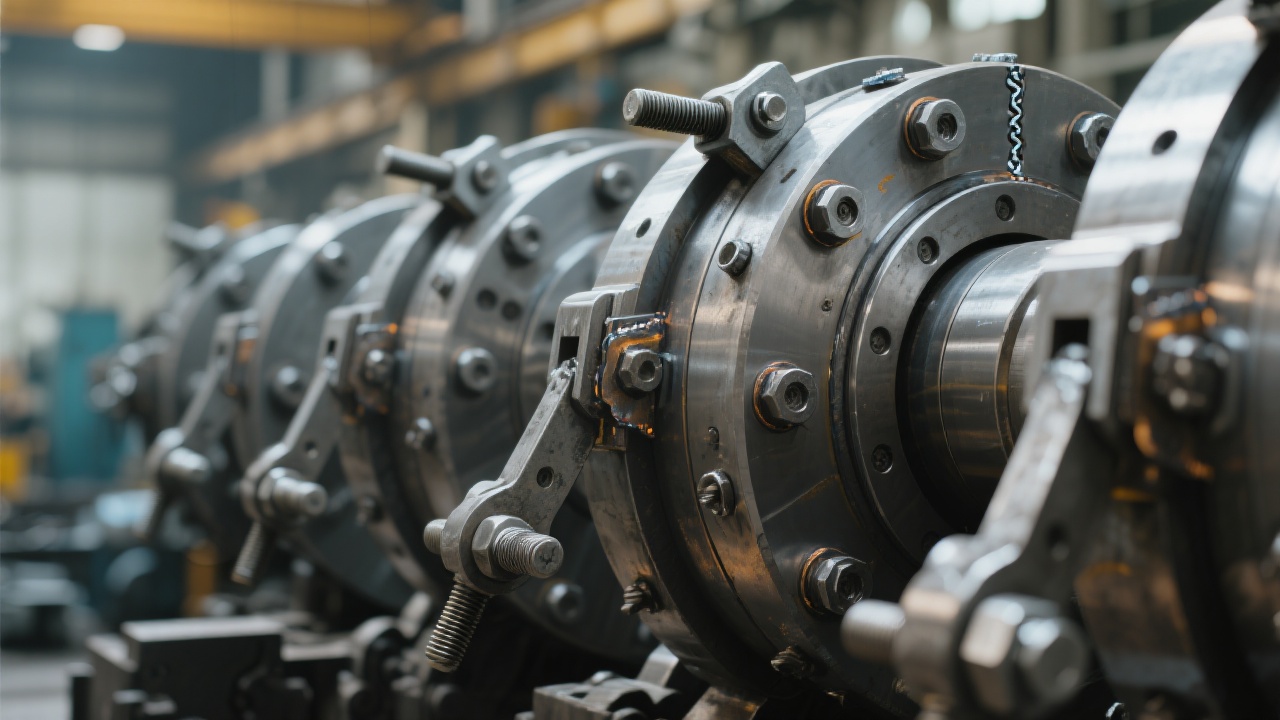

At the heart of the gravity-operated roll clamp’s success lies its ingenious self-activating mechanism. Using the natural force of gravity, the clamp automatically adjusts its gripping pressure according to the coil’s diameter and weight. This eliminates the need for complex hydraulic or pneumatic systems, reducing operational complexity and enhancing reliability.

Such simplicity translates into reduced maintenance downtime. Industry reports show that plants employing gravity-operated clamps have observed up to 20% less operational interruptions compared to traditional hydraulic clamps. This increased uptime directly impacts overall production throughput.

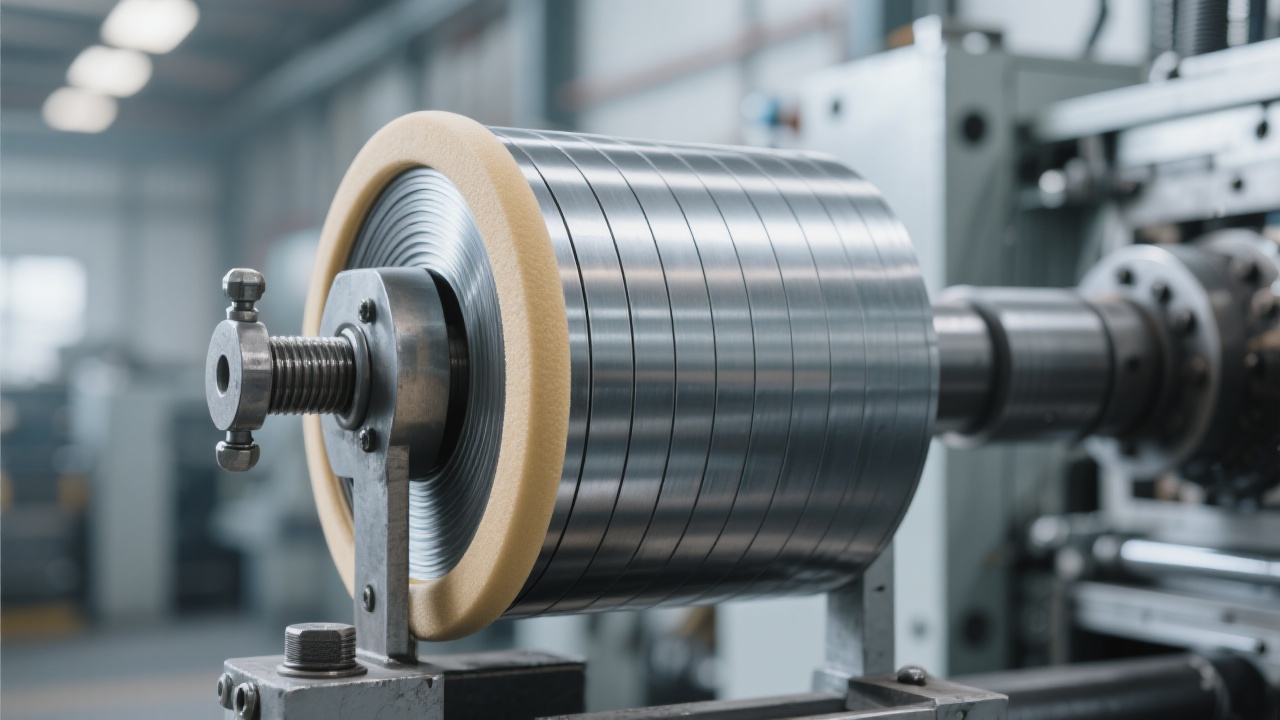

Industrial coils vary widely in diameter and weight. Gravity-operated clamps feature adaptable support arms, often equipped with polyurethane or copper-filled protective pads. These materials cushion the contact points, significantly minimizing surface damage risks to metal coils.

Laboratories within steel plants have confirmed that polyurethane pads reduce coil surface abrasion by up to 35%, preserving product integrity and value. The multirange capability of these clamps supports a broad spectrum of coil sizes, from smaller aluminum rolls as light as 500 kg to heavy steel coils exceeding 15 tons.

The protective efficiency of roll clamps directly correlates with their padding composition. Gravity-operated clamps leverage advanced materials such as copper-filled polyurethane pads that provide excellent shock absorption and resistance to wear.

These materials have industry certifications (e.g., ASTM D3574) indicating superior durability in harsh environments. Our case study with a leading non-ferrous metals processor reported a dramatic drop in coil surface defects—over 40% reduction—after switching to clamps with such padding.

Operational complexity often hinders adoption of new equipment. However, the gravity-operated roll clamp stands out for its intuitive design. Operators can master its use in under an hour without formal technical training. The self-regulating grip mitigates the risk of operator error.

Safety protocols are further enhanced with built-in mechanical stops preventing over-gripping, thus eliminating risks of coil deformation or accidental drops. Occupational safety data from steel mills show a significant decline in handling incidents following the adoption of this technology.

| Plant Type | Before Gravity Clamp | After Gravity Clamp | Key Improvements |

|---|---|---|---|

| Steel Rolling Mill | 45 mins downtime daily | 35 mins downtime daily | 22% reduction in downtime |

| Non-Ferrous Metal Processor | 12% coil damage rate | 7% coil damage rate | 42% fewer surface defects |

| Heavy Machinery Manufacturer | Complex operator training needed | Reduced to 1-hour orientation | Improved safety & faster onboarding |

With proven gains in efficiency, safety, and product protection, gravity-operated roll clamps clearly meet the pressing needs of today’s metallurgical plants and heavy industry operators. Their adoption represents a strategic investment in performance sustainability and operational excellence.

Discover How Gravity-Operated Roll Clamps Can Transform Your Heavy Lifting Today