Why More Warehousing and Logistics Companies Are Adopting Sliding Plate Ladle Clamps: Industry Trends and Practical Insights

24 08,2025

Industry Experience

This article explores the growing adoption of sliding plate ladle clamps in warehousing and logistics operations. Highlighting their efficient application across steel manufacturing, port transportation, metal processing, and storage environments, it examines how advanced transmission mechanisms, stable gripping performance, and low-maintenance designs significantly enhance handling safety and operational efficiency. Supported by real-world case studies and industry data, the discussion underscores why this innovative clamping solution is becoming indispensable for resolving heavy steel plate handling challenges across multiple sectors.

Why More Warehousing & Logistics Enterprises Choose Translating Plate Slab Clamps: Industry Insights & Practical Experiences

The modern industrial landscape, especially within warehousing and logistics, is increasingly confronting the challenge of handling heavy steel plates effectively and safely. As industries push towards greater automation and efficiency, the demand for reliable, low-maintenance equipment that reduces human error and enhances throughput is higher than ever. Among these innovations, translating plate slab clamps have emerged as pivotal tools that streamline steel handling across diverse sectors including steel manufacturing, shipping ports, metal fabrication, and storage facilities.

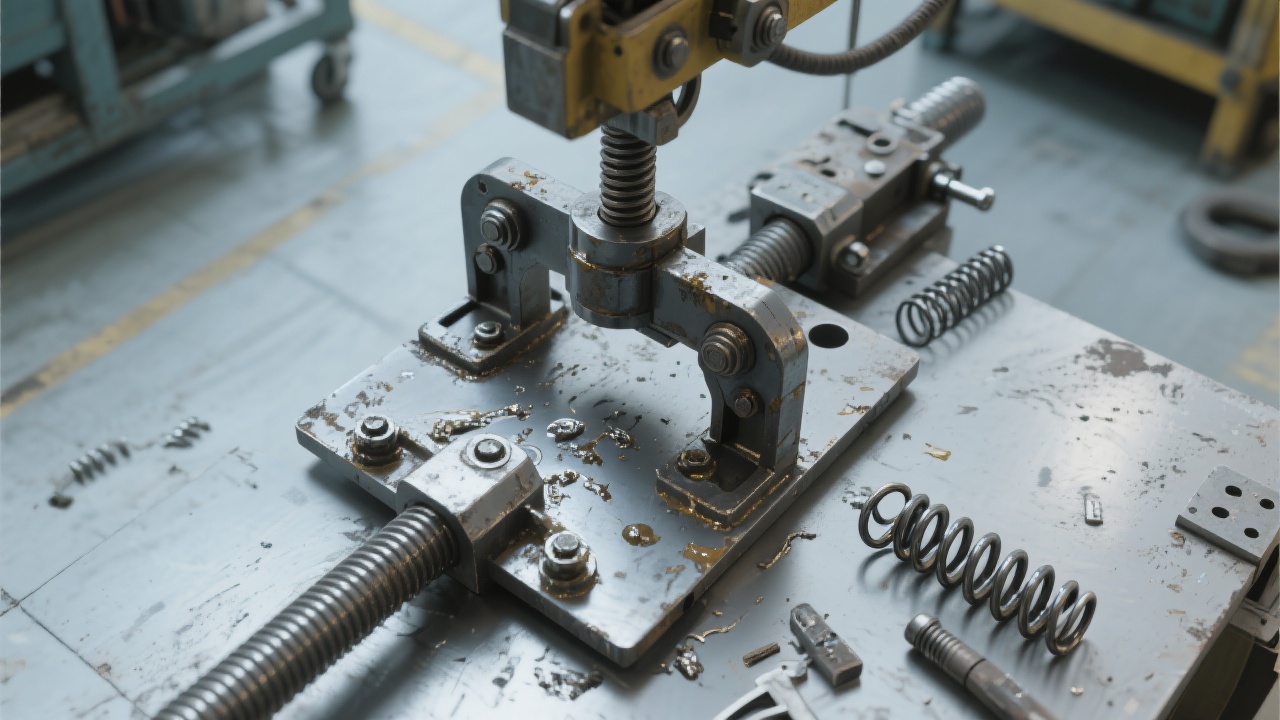

Core Technological Advantages of Translating Plate Slab Clamps

Translating plate slab clamps differentiate themselves by integrating advanced mechanical transmission mechanisms that ensure smooth and precise movement during lifting operations. These clamps are engineered to adapt to a broad range of steel plate thicknesses and dimensions, offering operators exceptional flexibility. Their design emphasizes ease of operation — with user-friendly controls that require minimal training — and significantly reduced maintenance costs due to durable construction materials and simplified components.

| Feature |

Benefit |

| Stable Transmission Mechanism |

Minimizes slippage and enhances handling precision |

| Compatibility with Multiple Plate Sizes |

Reduces need for multiple tools, streamlining inventory |

| Low Maintenance Requirement |

Cuts operational downtime and maintenance expenses |

| User-Friendly Operation |

Shorter training cycles and enhanced safety compliance |

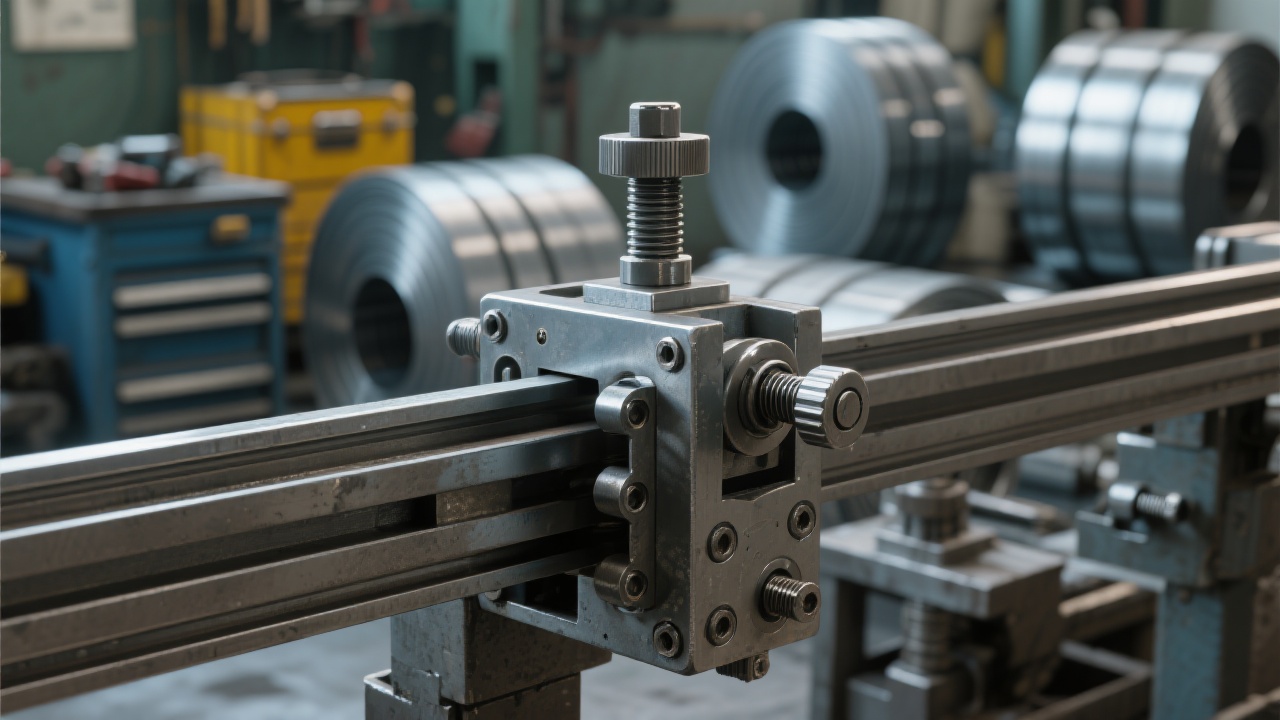

Real-World Applications Across Industries

Various sectors demonstrate increasing adoption of these clamps to optimize steel plate handling workflows:

- Steel Mills & Continuous Casting Plants: Translating plate slab clamps support continuous production lines by ensuring fast, secure transfer of hot slabs with minimal manual intervention.

- Seaports & Freight Terminals: The clamps facilitate rapid loading and unloading of steel cargo, reducing turnaround times in busy docks with a demonstrable 25% increase in handling efficiency.

- Metal Fabrication Factories: Versatile clamp design accommodates various plate thicknesses on assembly lines, streamlining batch processing and reducing operator fatigue.

- Heavy Equipment Transportation & Warehousing: Robust build quality supports repetitive lifting cycles and enhances workplace safety by lowering accident rates by up to 30%, according to independent user surveys.

“Since integrating the translating plate slab clamps, our port operations have seen a remarkable drop in manual mishandling. Not only has safety improved substantially, but the speed of container loading has allowed us to handle more shipments daily.” – Logistics Manager, Major International Seaport

Addressing Traditional Clamp Limitations: Distinctive Value Offered

Conventional clamp systems commonly suffer from unstable gripping, higher failure rates, and significant downtime caused by complex maintenance demands. In contrast, translating plate slab clamps bring tangible improvements:

- Enhanced Safety: Stable gripping mechanisms prevent plate slippage, reducing workplace accidents.

- Increased Uptime: Low-maintenance design permits extended continuous use without unplanned halts.

- Operational Flexibility: Accommodates a variety of plate dimensions, cutting tooling changeover times.

- Human Resource Optimization: Simplified operation reduces reliance on specialized labor, enabling efficient workforce allocation.

Aligning with Industry Trends: From Manual Handling to Intelligent Automation

The warehousing and logistics sectors are undergoing an important shift towards automated and intelligent material handling solutions. Translating plate slab clamps have positioned themselves as indispensable components within this evolution, enabling companies to:

- Enhance Process Reliability: Predictable and repeatable operations ensure higher production yield.

- Reduce Risks: Minimization of human error mitigates costly accidents and damages.

- Boost Throughput: Streamlined handling cycles accelerate overall warehousing and transport timelines.

- Optimize Costs: Lower labor intensity and maintenance expenses deliver stronger ROI.

Forward-looking companies acknowledge that investing in advanced handling equipment is not simply an operational upgrade but a strategic imperative to gain competitive advantages in an increasingly demanding market.

Technical Insights and Maintenance Benefits

Designed with high-strength alloys and precision-engineered moving parts, these clamps minimize wear and tear while maintaining peak gripping power across shifting workload profiles. Comprehensive testing indicates:

| Parameter |

Impact |

| Maintenance Intervals |

Extended by 40% over standard clamps |

| Operational Downtime Reduction |

Reduced by 22% |

| Safety Incident Rate |

Cut by 30% |

By combining mechanical robustness with intelligent design, translating plate slab clamps empower enterprises to pursue sustainable operational excellence without sacrificing safety or efficiency.